Ion source device for low-energy ion beam material preparing method

A low-energy ion beam and ion source technology, applied in the field of ion beams, can solve problems such as poor beam quality and ionization efficiency, high thermal power of ion sources, and affecting work stability, etc., to achieve simple and practical structure, improve ionization The effect of chemical efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

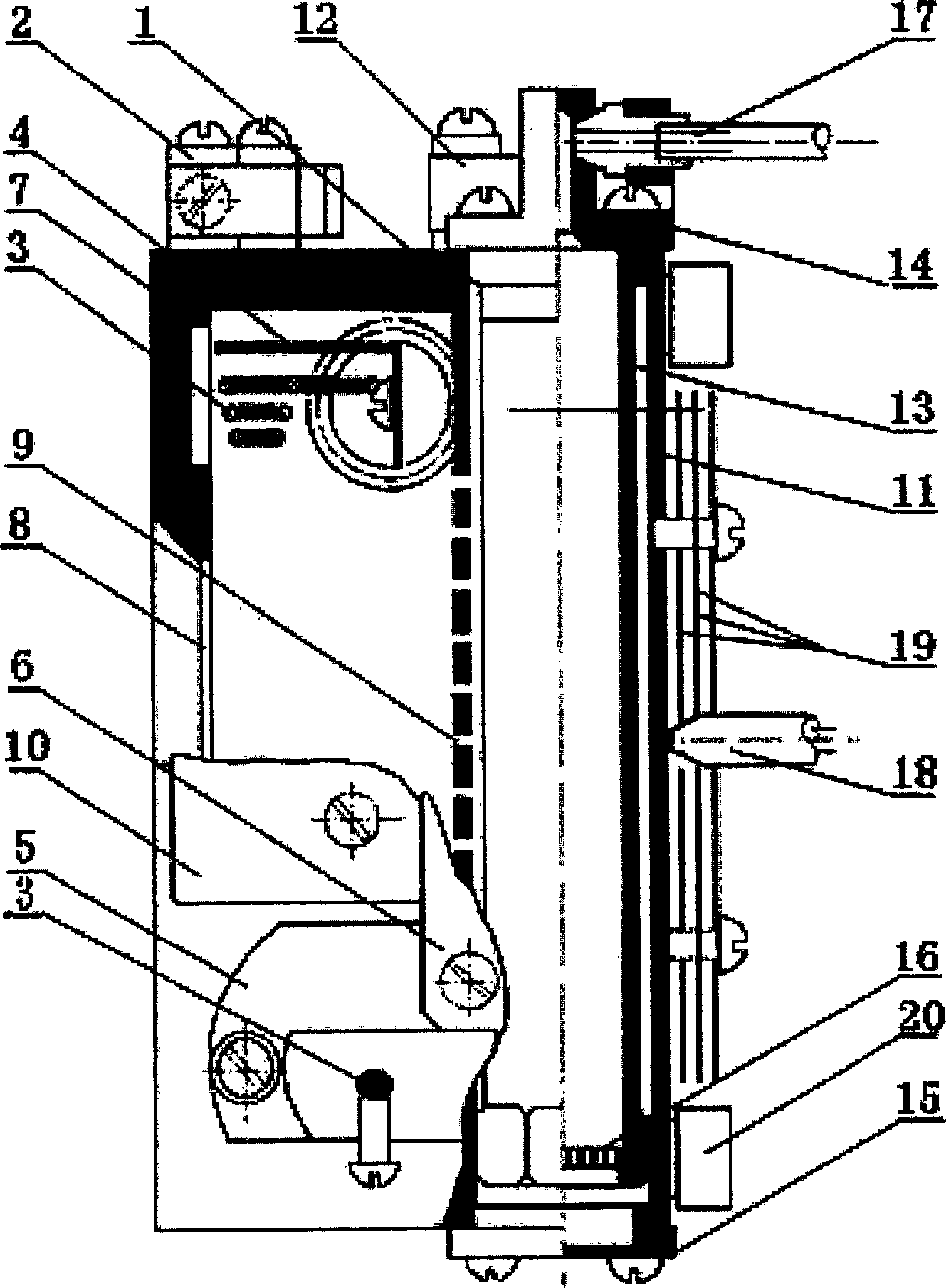

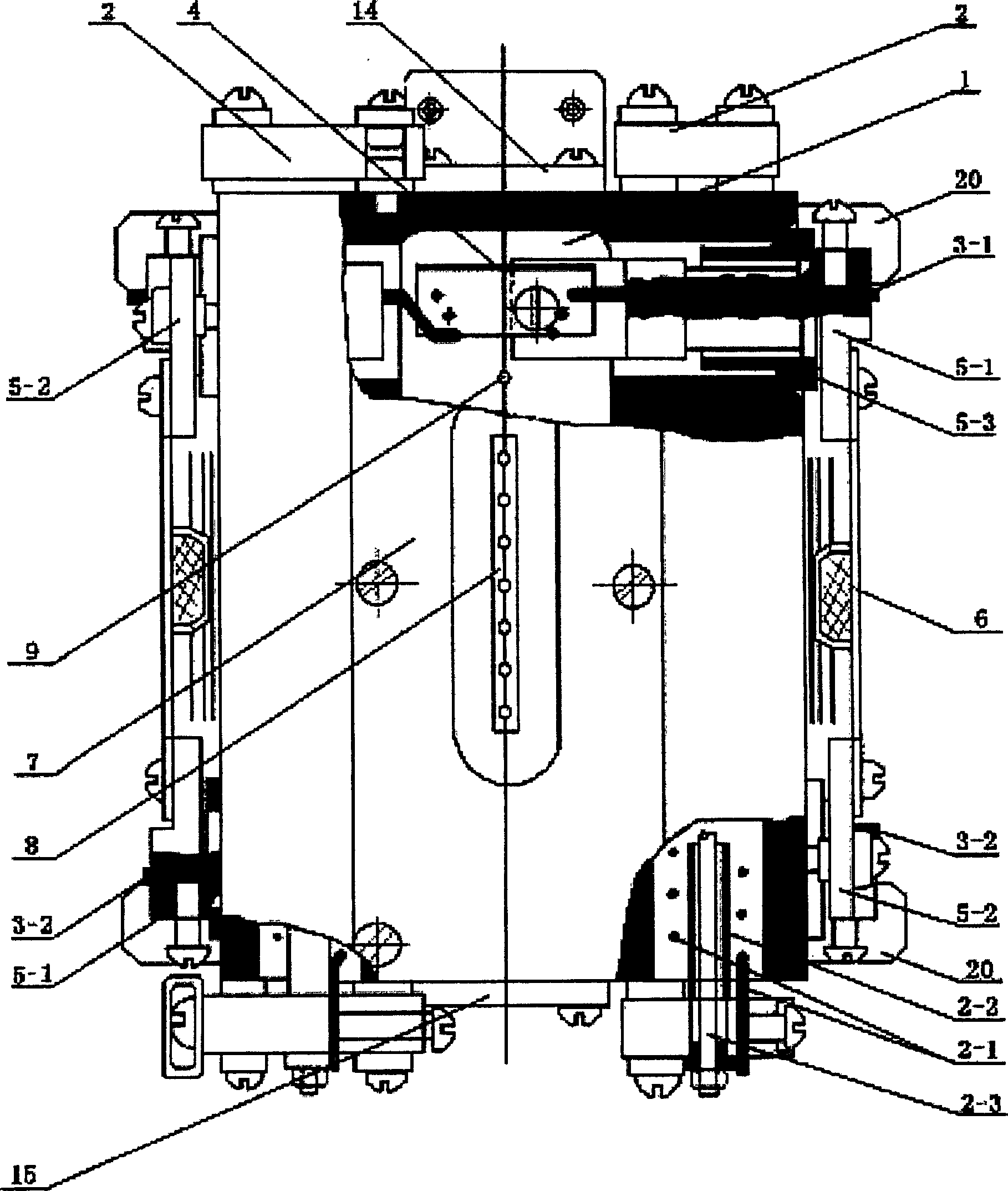

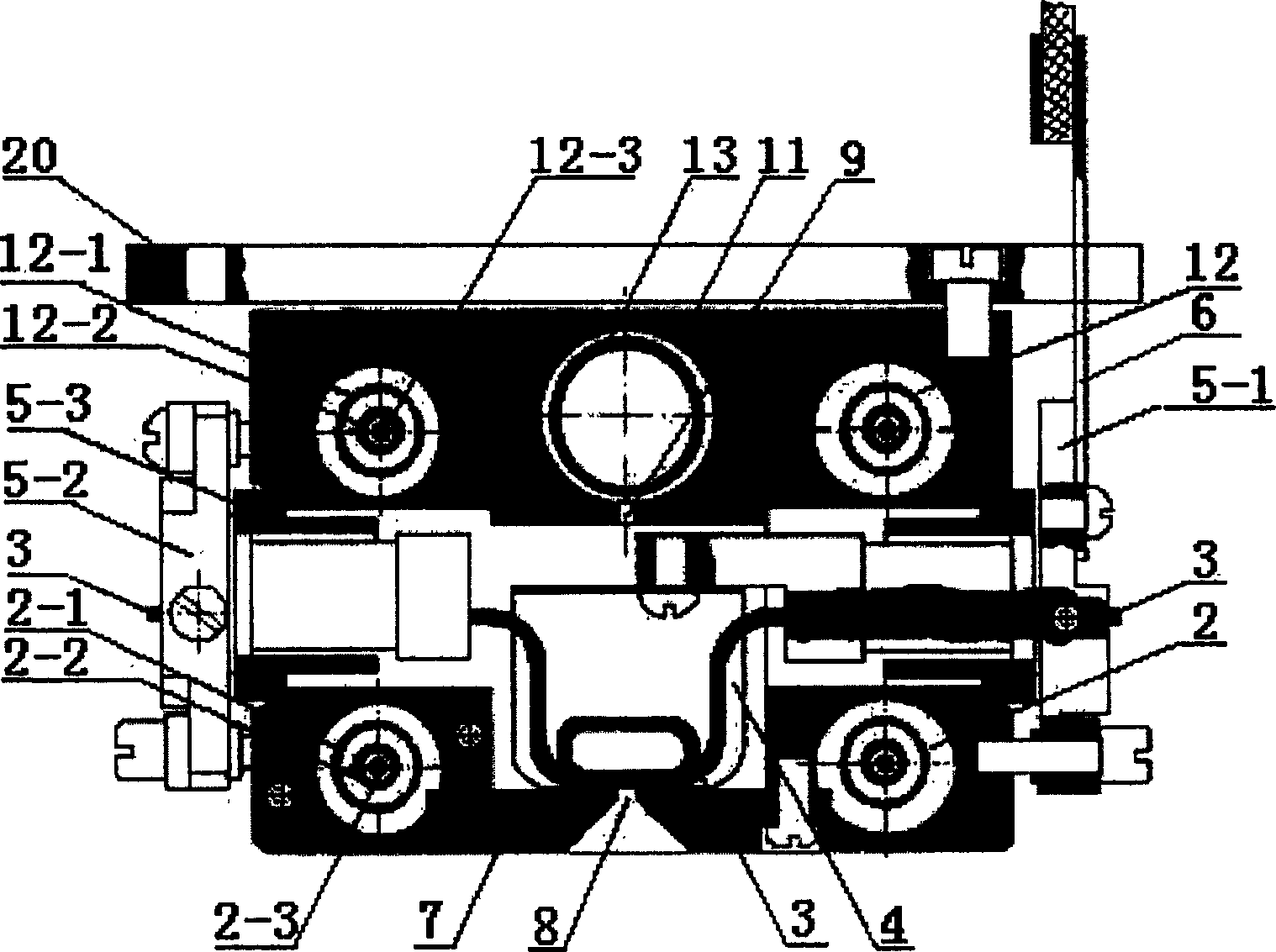

[0035] The structure and circuit diagram of the ion source device of the present invention are shown in FIG. 1 .

[0036]The ion source device includes two parts: an arc chamber body 1 and a crucible 11 , and each part is equipped with an auxiliary heating device: an arc chamber heating device 2 and a crucible heating device 12 . The arc chamber body 1 and the crucible 11 are designed to be integrated and separated from the front and back, and there is an exhaust air hole 9 communicating between them. The inner cavity of the arc chamber body 1 is also called an arc chamber or a vacuum discharge chamber, and there are upper and lower double helical filaments 3 (directly heated cathode) and a reflector 4 in the arc chamber. The wall of the arc chamber is at the anode potential, also known as the anode wall. The rear wall has exhaust air holes 9 communicating with the crucible 11, and the front cover plate 7 of the front wall has ion extraction slits 8. The double-helical filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com