Shallow junction shield groove technique for protecting active region area

A technology for isolating trenches and active areas, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as reducing the effective area of the active area, affecting the high density of devices and CD control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

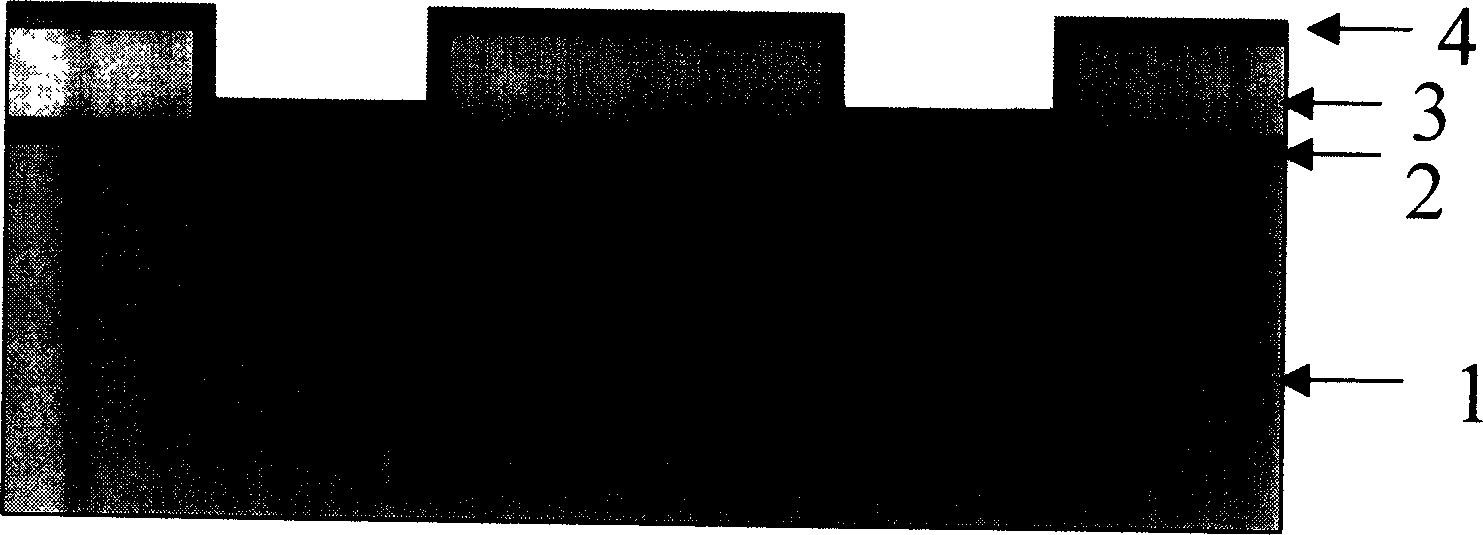

[0031] The present invention is in conventional STI process, reaches the above-mentioned object by the method for increasing a MASK and relevant process step, therefore, the main process step of process method of the present invention is listed below (particularly different from conventional STI process flow The process steps), that is, in the STI process flow, the process before the STI planarization, and the subsequent processes are consistent with the processes in other conventional STI processes, and will not be repeated here.

[0032] The following is the process steps before STI CMP in the process flow of this STI (see the description of the drawings):

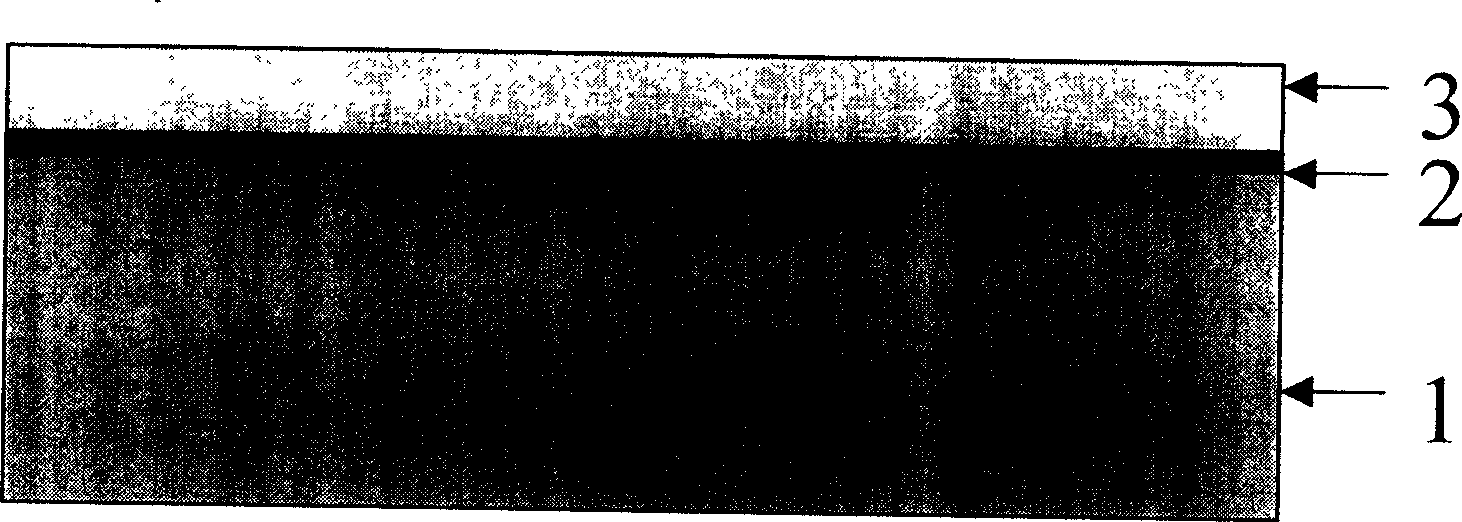

[0033] 1. Deposit silicon oxide and silicon nitride layers, as the HARD MASK defined by STI, the thicknesses are silicon oxide: 10nm; silicon nitride: 200nm; ( figure 1 )

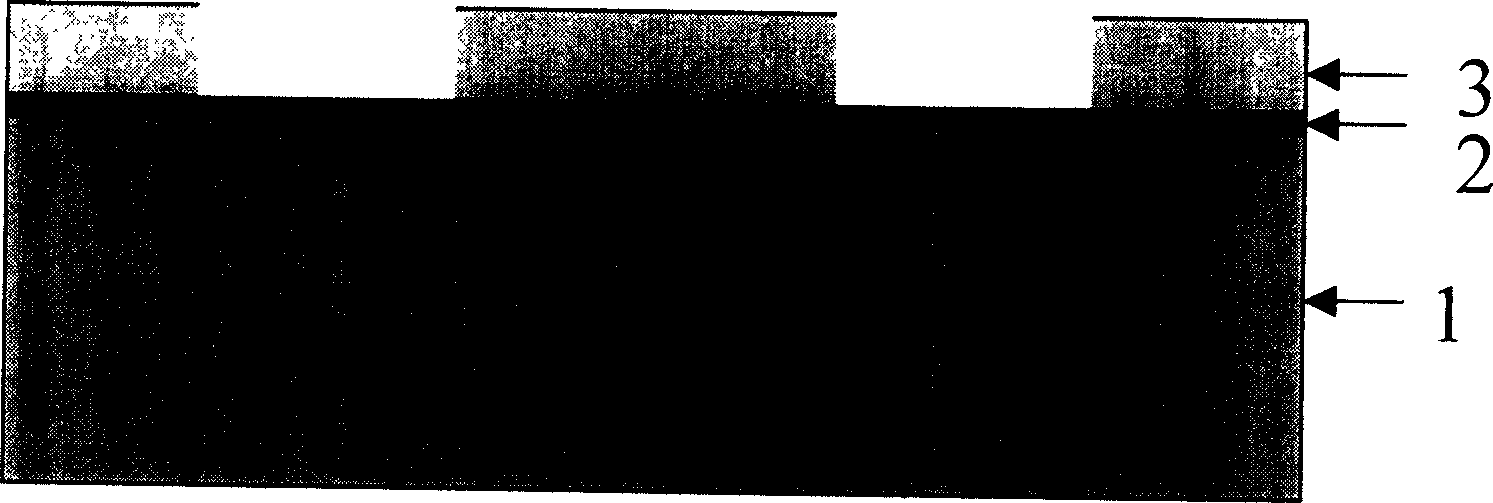

[0034] 2. Use STI MASK to define the STI and active area, that is, the photolithography process

[0035] 3. Etching silicon oxide to expose the STI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com