Drying method for superfine aluminium hydroxide

A technology of ultra-fine aluminum hydroxide and drying method, which is applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc. It can solve problems such as poor fluidity, inability to use drying methods, and high initial viscosity, so as to ensure product quality and simplify operation , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

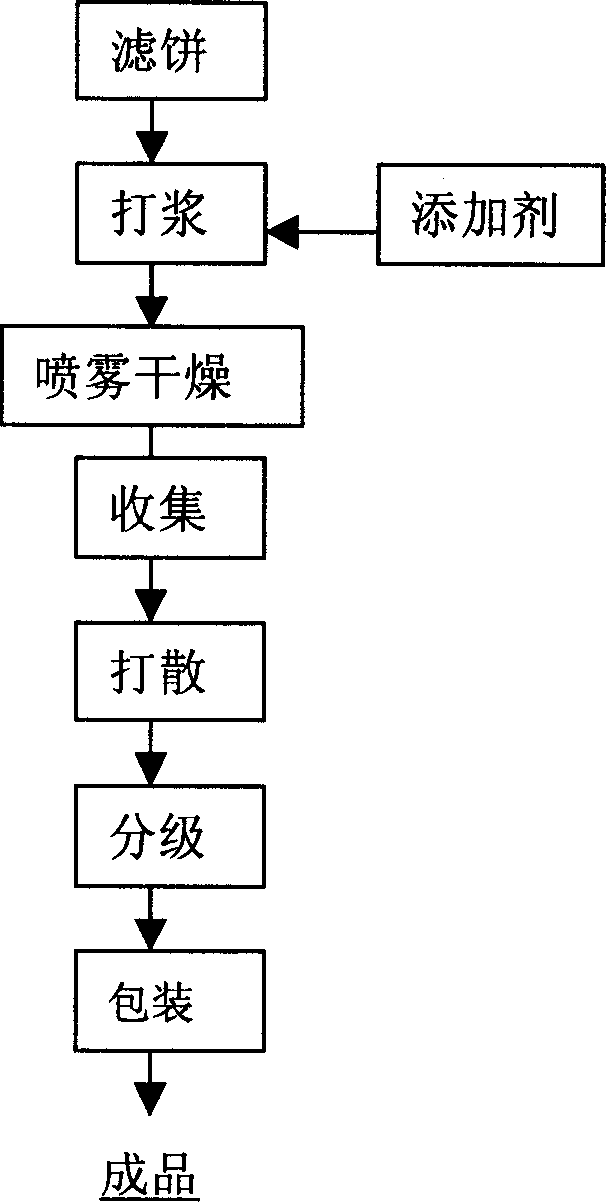

Image

Examples

Embodiment 1

[0014] Send the ultra-fine aluminum hydroxide filter cake with a water content of 40% at 40°C to the beating tank, add ammonium polyacrylate with a weight of 0.36% on a dry basis of ultra-fine aluminum hydroxide, stir to make the filter cake become an easy-flowing slurry, and then The pump pumps it to the top of the drying tower (hot air inlet temperature 340°C) for atomization, and at the same time contacts with hot air for instant drying, and the dry material flows out from the bottom of the tower (outlet temperature 115°C), and the product is obtained after being dispersed, classified, and collected. Its moisture content is 0.08%.

Embodiment 2

[0016] Send the ultra-fine aluminum hydroxide filter cake with a water content of 45% at 35°C to the beating tank, add 0.42% ammonium polyacrylate of the ultra-fine aluminum hydroxide dry weight, stir to make the filter cake become an easy-flowing slurry, and then Pump it to the top of the drying tower (hot air inlet temperature 360°C) for atomization, and at the same time contact with hot air for instant drying, the dry material flows out from the bottom of the tower (outlet temperature 123°C), add 0.5% KH570 silane to the disperser , and then collected by classification, the product has a moisture content of 0.057%.

Embodiment 3

[0018] Send the ultra-fine aluminum hydroxide filter cake with a water content of 50% at 42°C to the beating tank, add 0.28% ammonium polyacrylate and 0.5% titanate based on the dry weight of ultra-fine aluminum hydroxide, and stir to make the filter cake easy The flowing slurry is then pumped to the top of the drying tower (hot air inlet temperature 370°C) for atomization, and at the same time it is in contact with hot air for instant drying, and the dry material flows out from the bottom of the tower (outlet temperature 120°C), after being dispersed and classified 1. The captured product has a water content of 0.067%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com