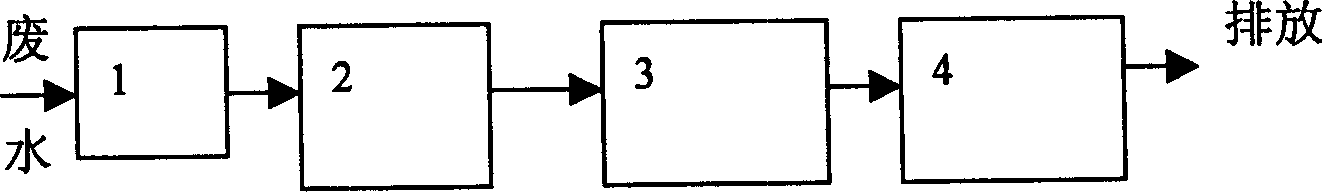

Combined effluent treating process of photooxidizing Fenton's reaction, flocculation and microbial degradation

A technology of microbial degradation and Fenton reaction, applied in flocculation/sedimentation water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc., can solve problems such as high cost, large amount of reagents, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The treatment object of the present invention is phenol and carbendazim pesticide wastewater: the values of COD before treatment are 1500mg / L and 20000mg / L respectively.

[0033] Light-assisted Fenton reaction conditions: Add 12.4mL H to 1 liter of wastewater 2 o 2 , 8mL 1mol / L FeSO 4 solution. A light source with 1-3 low-pressure mercury lamps and 1-3 medium-pressure mercury lamps connected in series is used, and the light source is installed in parallel in the photochemical reaction pool. The light source is placed in the quartz sleeve, and the two ends of the quartz sleeve are fixed and sealed on the photochemical reaction tank. The waste water flows into the box from the lower part of the photochemical reaction tank, and can also flow out from the upper part and then flow back into the prereactor. The waste water is photochemically processed in the reaction tank. Help Fenton reaction; react in the presence of light for 0.5-2 hours;

[0034] After the reaction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com