Small size core free motor and wireless operating model game apparatus

A coreless, motor technology, applied in toys, remote control toys, electromechanical devices, etc., can solve the problems of coil size deformation, poor thermal conductivity, heat accumulation, etc., and achieve the effects of suppressing size deformation, improving heat resistance, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

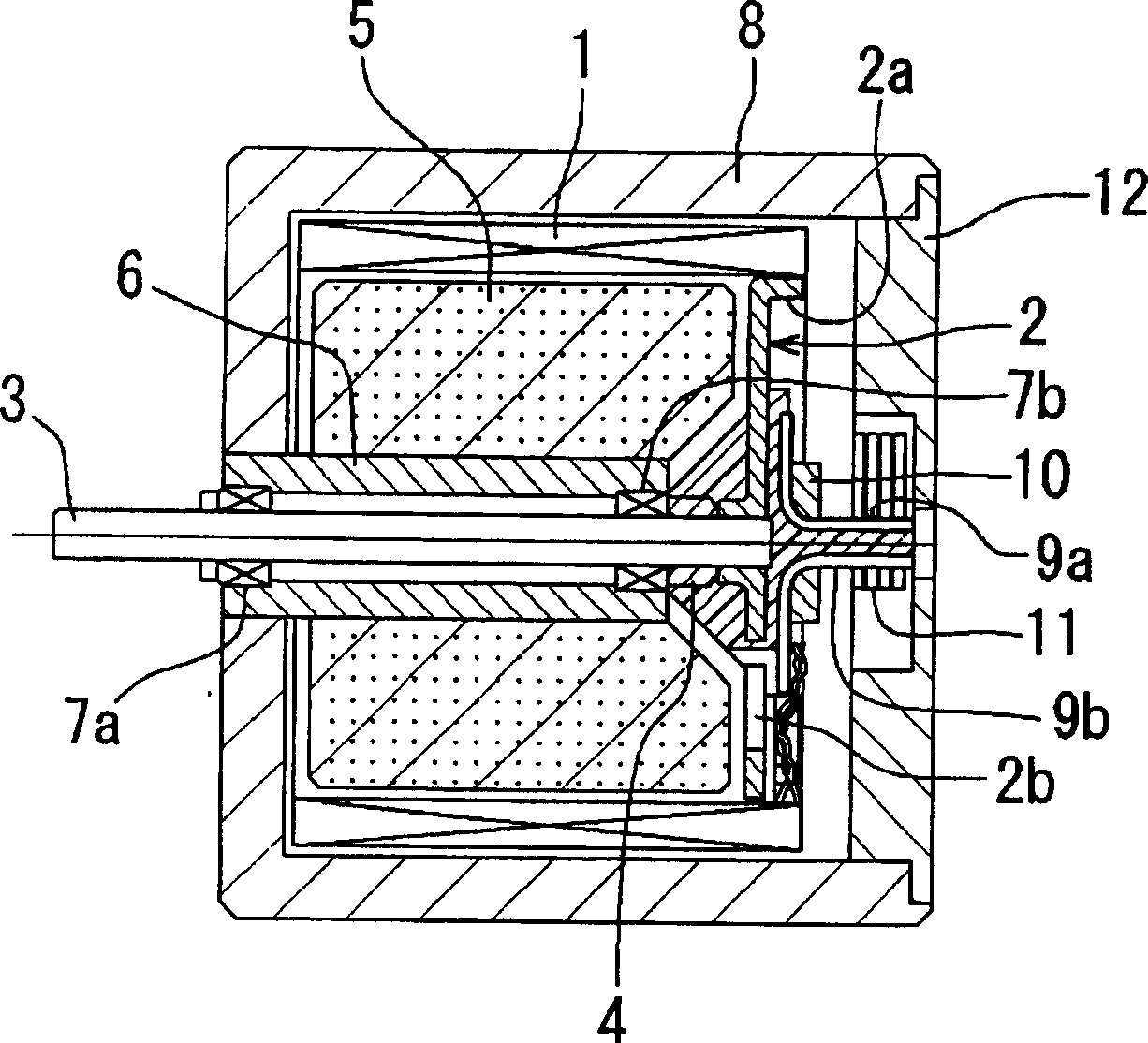

[0019] figure 1 A small coreless motor according to an example of the present invention is shown in cross section. In the figure, reference numeral 1 denotes a cylindrical coil, 2 denotes a hub for holding the coil 1, 3 denotes a rotating shaft for holding the hub 2, 4 denotes a stop ring of the hub 2, and 5 denotes a hub for holding the coil 1. 6 is a bearing box, 7a, 7b is a bearing, 8 is a housing, 9a, 9b is a rectifier, 10 is a rectifier stand, 11 is a brush, and 12 is a brush stand.

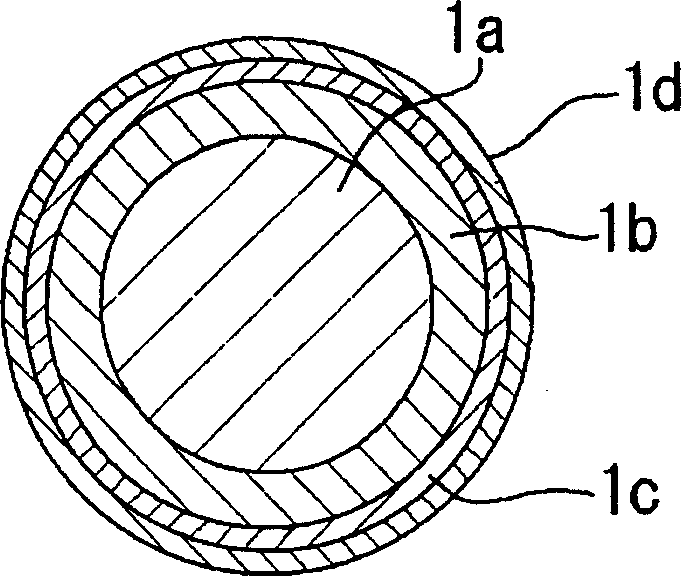

[0020] In this structure, in a preferable embodiment, the coil 1 is formed into a cylindrical shape by winding a copper-clad aluminum wire. Such as figure 2 As shown, the copper-clad aluminum wire is formed in the following manner: a core 1a is made of aluminum or an aluminum alloy with a small specific gravity, a copper film 1b is coated on the outer periphery of the core 1a, and an insulating coating 1c is coated on the copper film 1b On the outer periphery of the insulating coating 1c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com