Process for producing carbonyl compound

A technology of carbonyl compounds and compounds, applied in the field of production of carbonyl compounds, which can solve the problems of low reactivity and inability to obtain favorable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

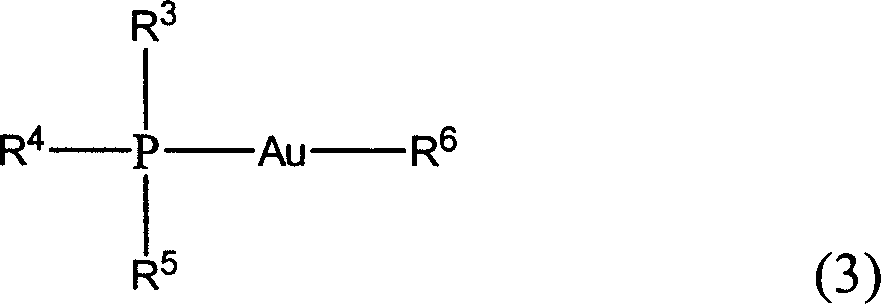

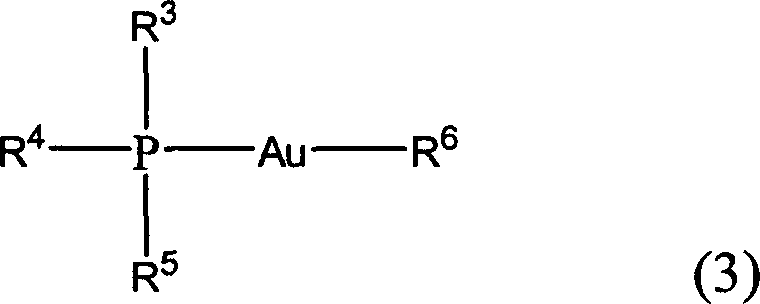

[0088] 0.005g methyl (triphenylphosphine) gold (0.01mmol) is dissolved in 1ml and forms a solution in the solvent shown in table 1, adds the 1-octyne (1mmol) of 0.11g in this solution and by the concentrated sulfuric acid ( 0.5mmol) dissolved in 0.5ml of water to form an aqueous solution. Table 1 summarizes the yield of 2-octanone after stirring at 70 °C for 1 hour.

[0089] Table 1

[0090] Example

Embodiment 5

[0092] The reaction was performed in the same manner as in Example 1 except that 1-butyl-3-methylimidazolium hexafluorophosphate was used as a solvent. As a result, 2-octanone was obtained in a yield of 89%.

Embodiment 6

[0094] The reaction was performed in the same manner as in Example 5 except that 0.01 g of methyl(triphenylphosphine)gold (0.02 mmol) was used. As a result, 2-octanone was obtained in a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com