Optical recording material and optical recording medium

A technology for optical recording media and optical recording materials, applied in the direction of optical recording media, recording carrier materials, optical recording/reproduction, etc., capable of solving problems such as insufficient solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

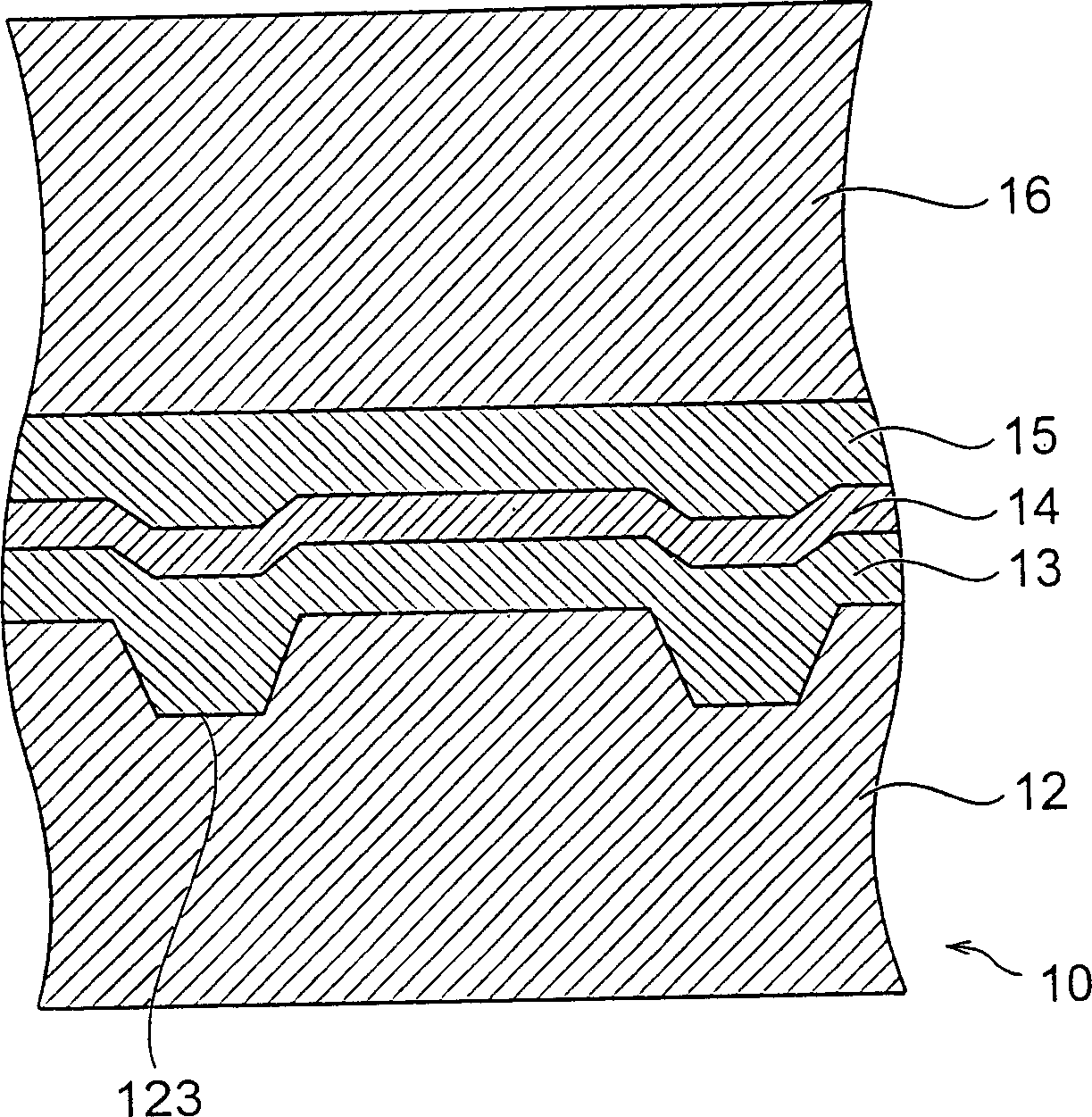

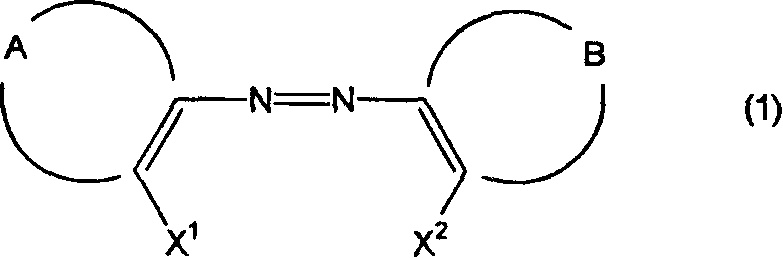

[0126] A polycarbonate resin substrate having a diameter of 120 mm and a thickness of 0.6 mm having pregrooves (180 nm in depth, 0.30 μm in width, and 0.74 μm in pitch) on one side was prepared. Separately, salt-forming dye 1 represented by the following general formula (3) was added to 2,2,3,3-tetrafluoropropanol to prepare a recording layer coating solution having a content of 1.0% by weight.

[0127]

[0128] The obtained coating solution was applied to the surface of the polycarbonate resin substrate on which the pregroove was formed, and dried to form a recording layer (thickness: 100 nm).

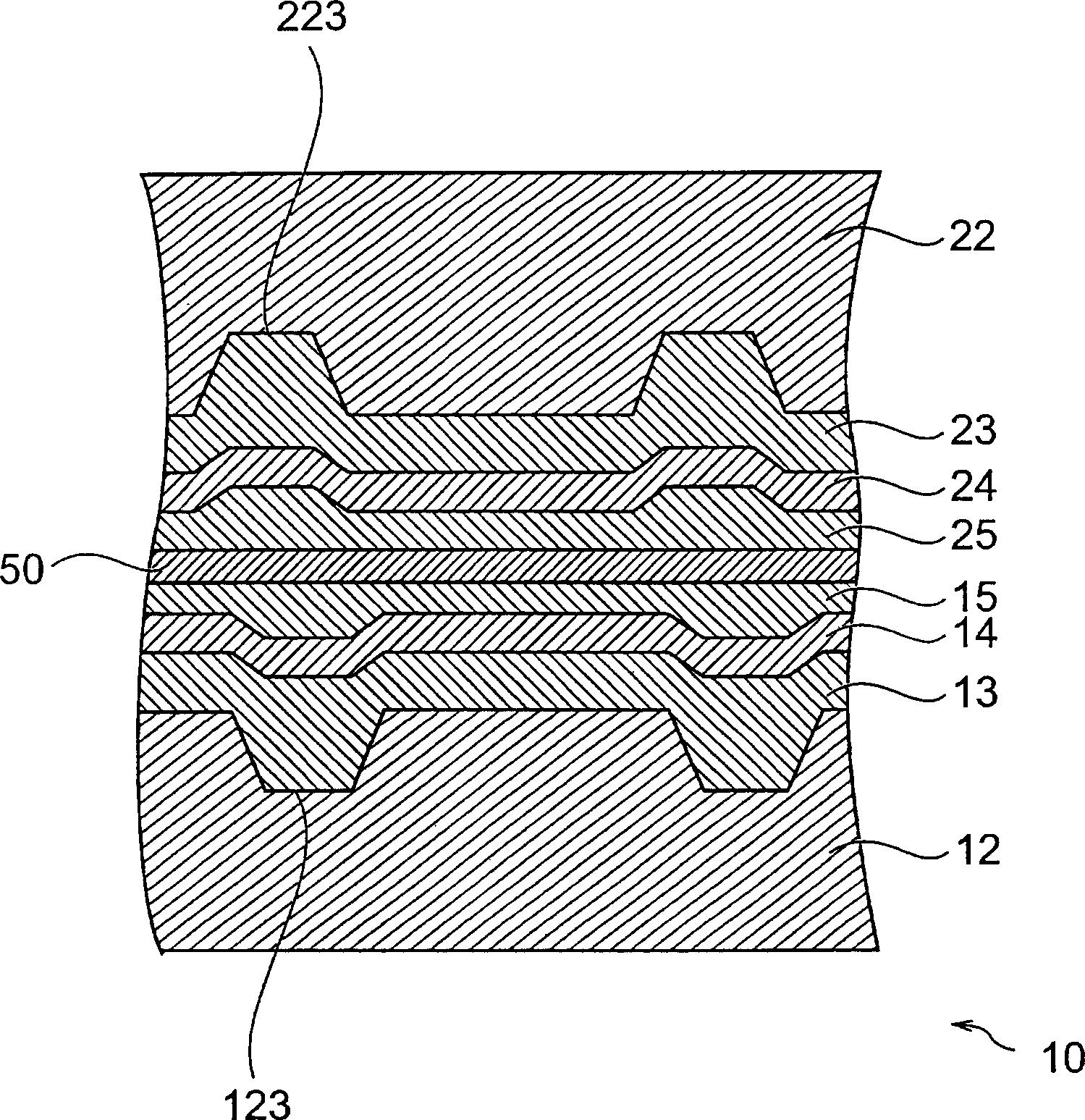

[0129] Then, an Ag reflective layer (85 nm thick) was formed by sputtering on the recording layer, and a transparent protective layer (5 μm thick) made of ultraviolet curable acrylic resin was formed on the Ag reflective layer to obtain a laminated structure. Two pieces of this laminated structure are produced, with the protective layer as the inner side, and they are pasted with a...

Embodiment 2

[0131] An optical recording disc was produced in the same manner as in Example 1 except that the salt-forming dye 2 represented by the following general formula (74) was used instead of the salt-forming dye 1 in Example 1.

[0132]

Embodiment 3~13、 comparative example 1~3

[0134] In Examples 3 to 13 and Comparative Examples 1 to 3, optical recording disks were produced in the same manner as in Example 1 except that dye compositions 3 to 13 shown in Table 1 were used instead of salt dye 1, respectively. In Table 1, numbers in parentheses represent symbols of the above-mentioned and following chemical structural formulas.

[0135] Salt

Cyanoin dye

Composition (weight%)

Composition (weight%)

Example 3

(73)

40

(61)

60

Example 4

(73)

50

(61)

50

Example 5

(74)

40

(65)

60

Example 6

(74)

40

(66)

60

Example 7

(74)

40

(67)

60

Example 8

(74)

40

(68)

60

Example 9

(73)

30

(61)

70

Example 10

(73)

60

(61)

40

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com