Photoetching imaging polarized controller with high value aperture

A technology with high numerical aperture and polarization control, which is applied in photolithographic exposure devices, micro-lithography exposure equipment, optics, etc., can solve the problems of large influence of lithography graphics and shortening of exposure wavelength, and achieve simple and convenient design and improved resolution Power and depth of focus, the effect of improving imaging contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

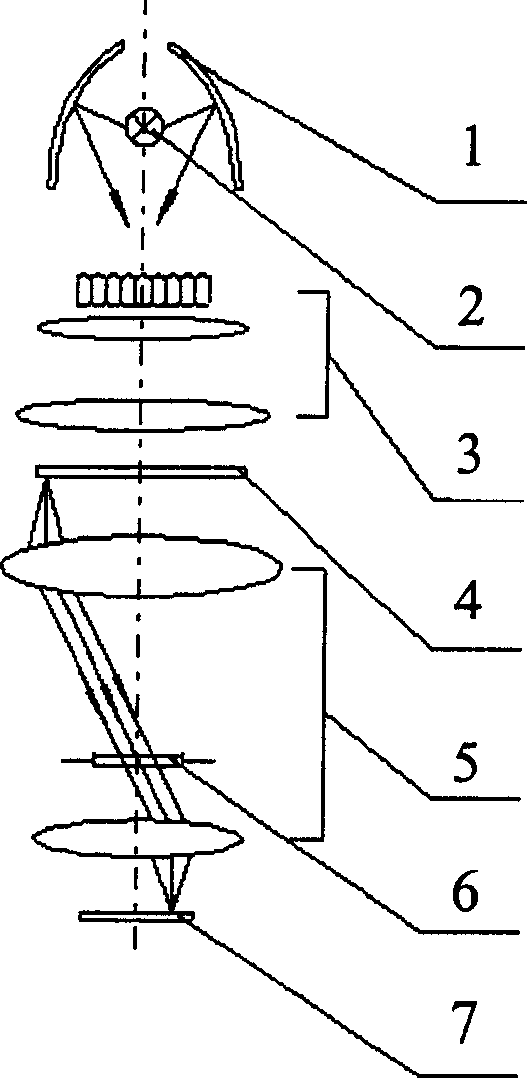

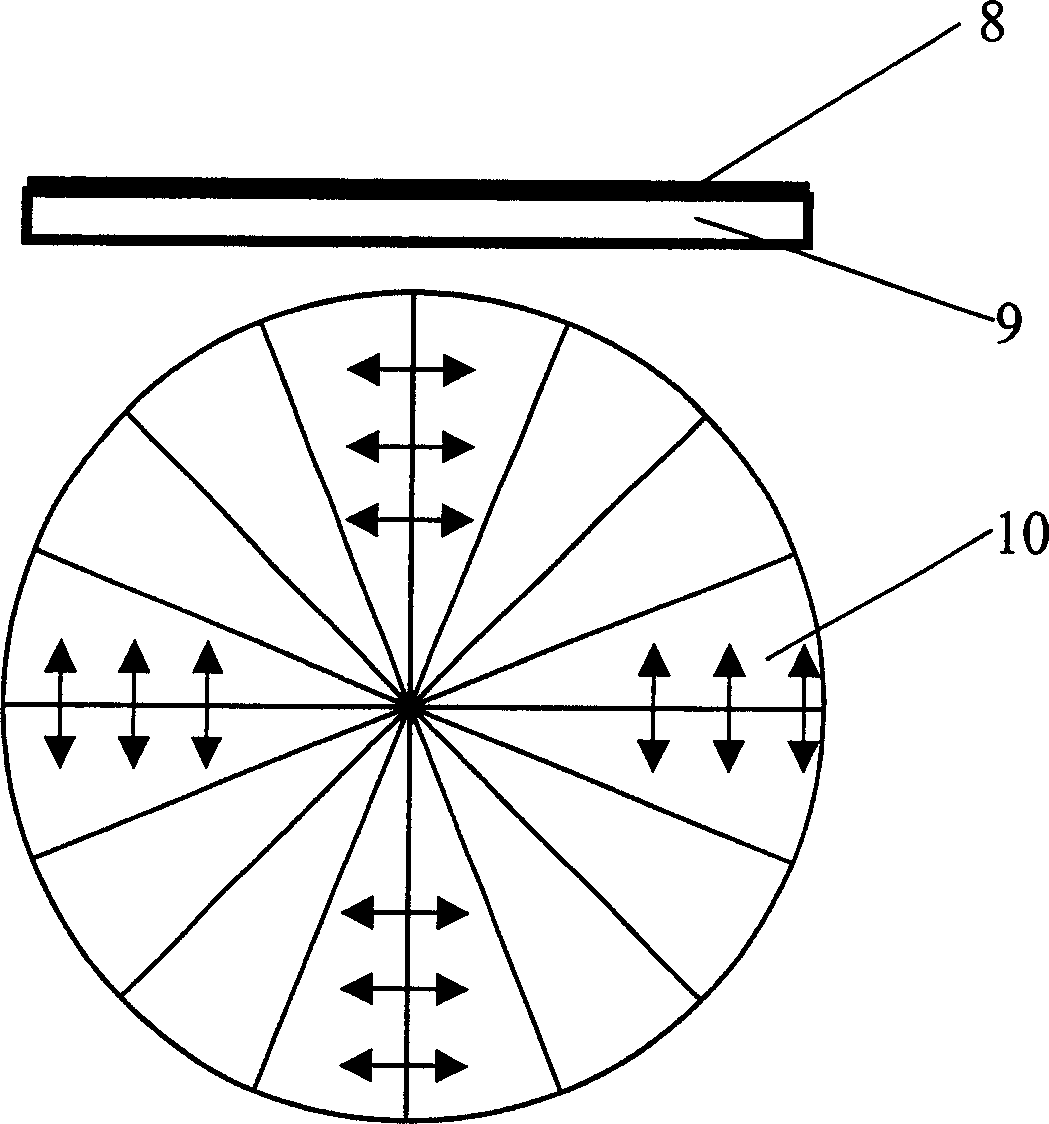

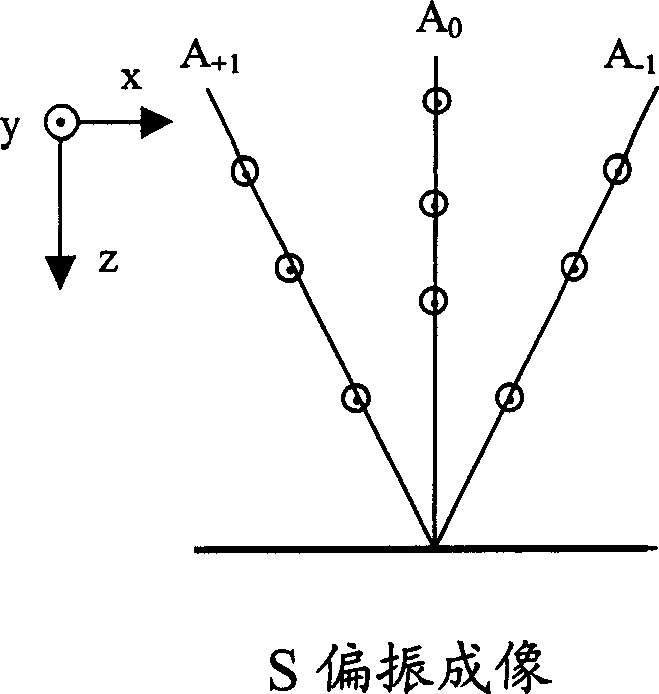

[0016] Such as figure 1 As shown, the present invention is composed of an ellipsoid mirror 1, a light source 2, a high-energy and high-uniform illumination component 3, a mask plate 4, a projection lithography objective lens 5, a polarization pupil device 6, and a silicon wafer 7. The light emitted by the light source 2 is collected by the ellipsoidal mirror 1, and the light is gathered through the high-energy and high-uniform illumination component 3 (the uniformity can reach ±2.5%) to illuminate the mask plate 4, and the ultra-fine feature patterns on the mask plate 4 are projected The lithography objective lens 5 projects an image onto the silicon wafer 7 . A polarization pupil device for controlling the polarization of the imaging beam is placed on the pupil plane of the projection lithography objective lens. The polarization pupil device makes the imaging beam unobstructed, changes the pupil function of the projection optics lithography imaging optical system, and the tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap