Mine gas anti-knock additive and its preparing method

An anti-explosion agent and gas technology, which is applied in mining equipment, dustproof, earth-moving drilling and mining, etc., can solve the problems of inability to eliminate gas, gas life safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

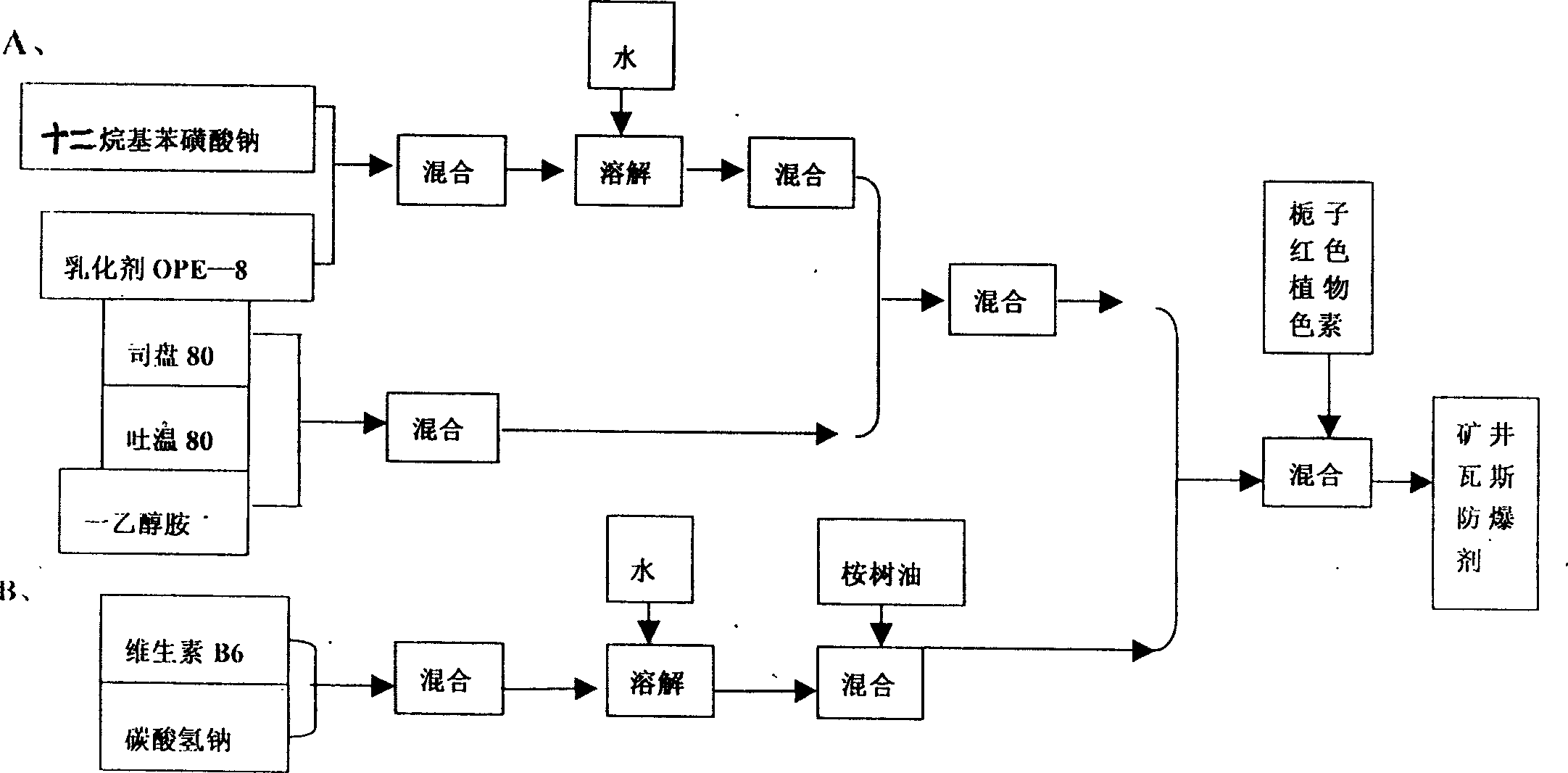

[0027] The composition of mine gas anti-explosion agent of the present invention and the processing step of preparation method thereof:

[0028] The formula of mine gas anti-explosion agent is made up of A and B two components, according to the following weight ratio relationship of each component in the two components, each component is weighed for future use:

[0029] The ingredients and parts by weight of component A are: Span 80---6, Tween 80--6, monoethanolamine--4, sodium dodecylbenzenesulfonate--66, emulsifier OPE-8- -12, water -100;

[0030] The components and parts by weight of component B are: vitamin B6-1, sodium bicarbonate-16, eucalyptus oil-3, gardenia red plant pigment-0.5, water-170.

[0031] a. Preparation of component A: Weigh sodium dodecylbenzenesulfonate and emulsifier OPE-8 according to the weight of the formula, release the container, mix them uniformly, add water to dissolve and mix uniformly to obtain component A1; Parts by weight of the formula Weig...

Embodiment 2

[0036] The composition of mine gas anti-explosion agent of the present invention and the processing step of preparation method thereof:

[0037] The formula of mine gas anti-explosion agent is made up of A and B two components, according to the following weight ratio relationship of each component in the two components, each component is weighed for future use:

[0038] The ingredients and parts by weight of component A are: Span 80---29, Tween 80--29, monoethanolamine--19, sodium dodecylbenzenesulfonate--330, emulsifier OPE-8- -59, water -390;

[0039] The components and parts by weight of component B are: vitamin B6-5, sodium bicarbonate-14, eucalyptus oil-79, gardenia red plant pigment-2, water-900.

[0040] According to above-mentioned formula, the preparation method of this mine gas explosion-proof agent is the same as embodiment 1.

Embodiment 3

[0042] The composition of mine gas anti-explosion agent of the present invention and the processing step of preparation method thereof:

[0043] The formula of mine gas anti-explosion agent is made up of A and B two components, according to the following weight ratio relationship of each component in the two components, each component is weighed for future use:

[0044] The ingredients and parts by weight of component A are: Span 80---14, Tween 80--14, monoethanolamine--12, sodium dodecylbenzenesulfonate--74, emulsifier OPE-8- -20, water -180;

[0045] The ingredients and parts by weight of component B are: vitamin B6-1.8, sodium bicarbonate-26, eucalyptus oil-11, gardenia red plant pigment-1.3, water-250.

[0046] According to above-mentioned formula, the preparation method of this mine gas explosion-proof agent is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com