System and method of water treatment

A water treatment system and ejector technology, applied in water treatment devices, natural water treatment, water/sewage treatment, etc., to achieve the effect of inhibiting erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

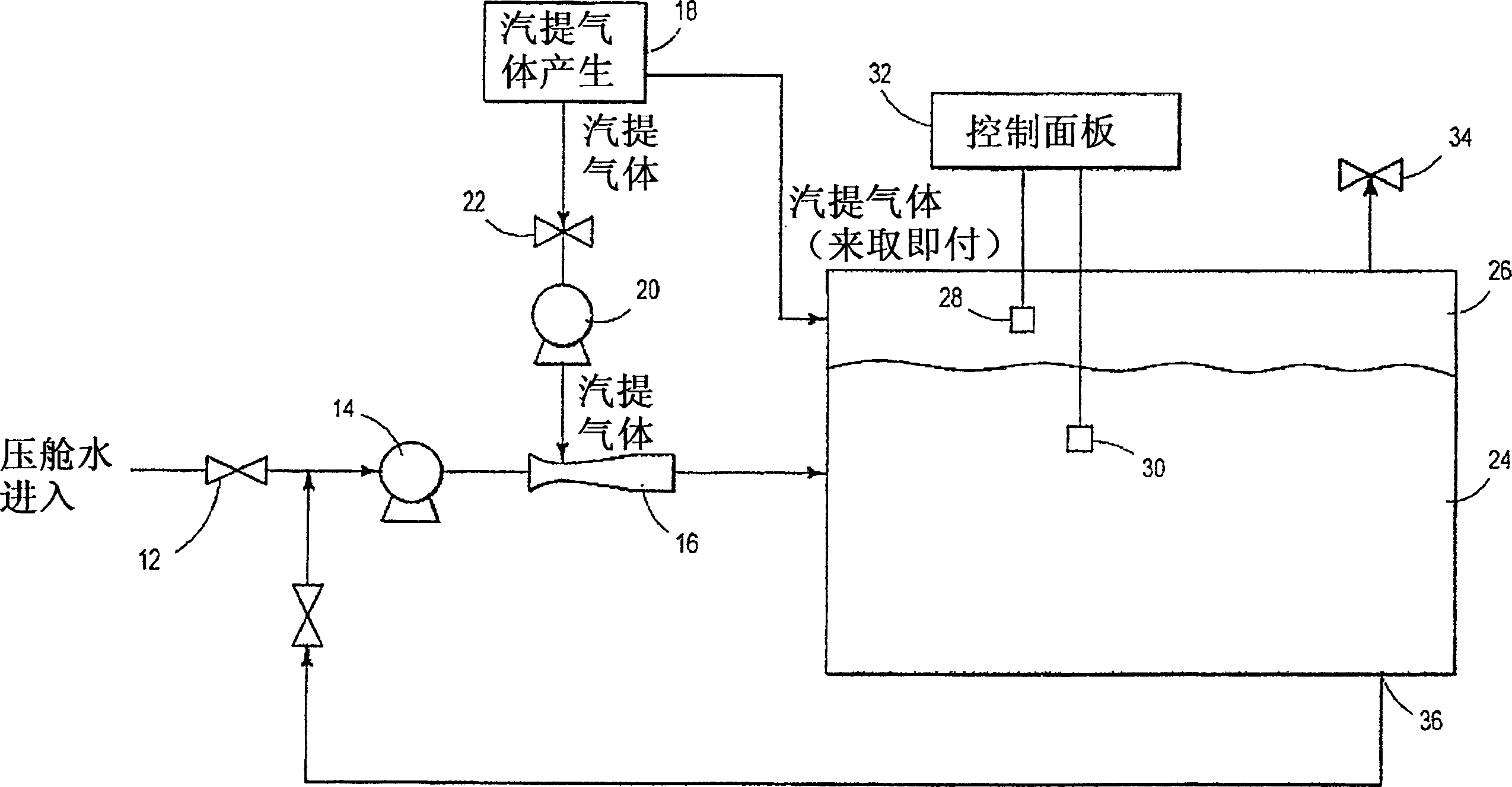

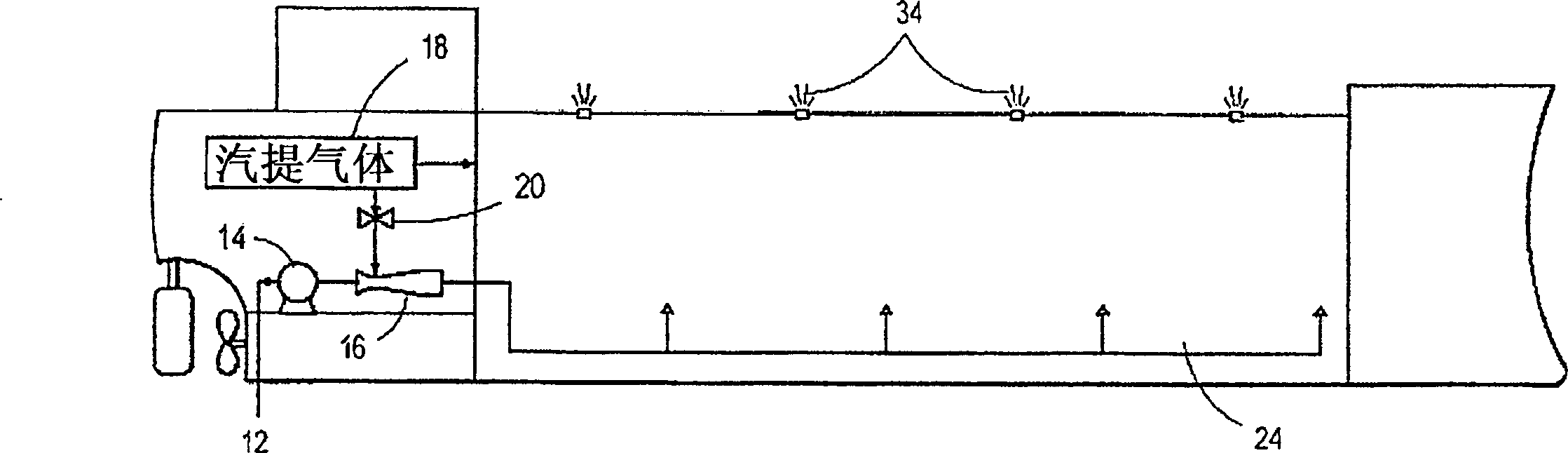

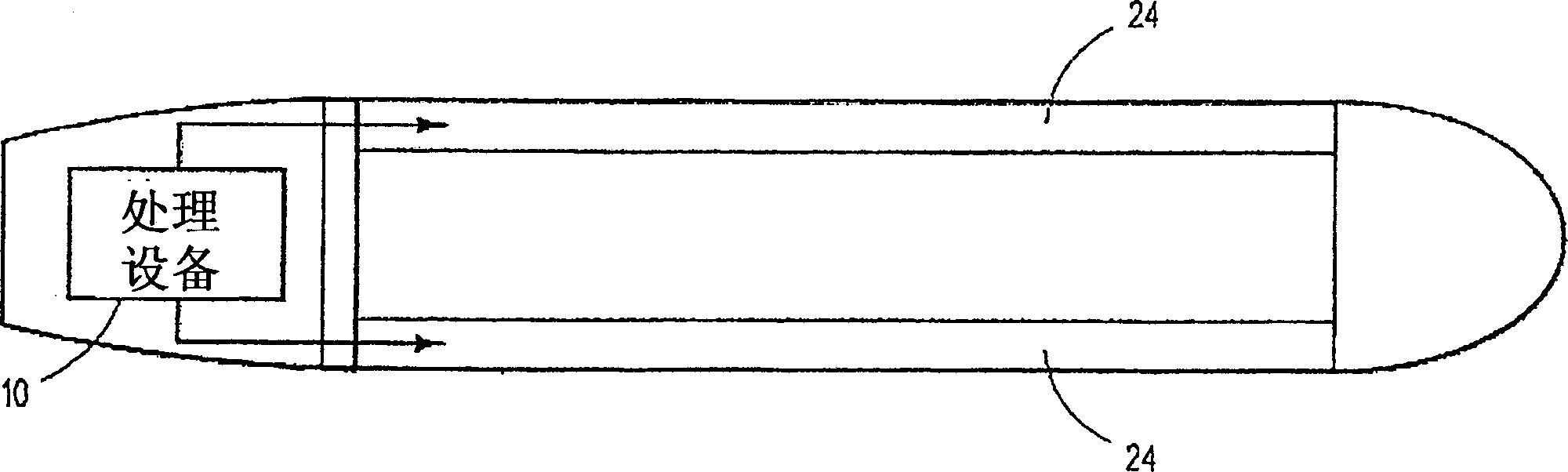

[0042] Referring now to the accompanying drawings, in particular Figures 1 to 5 , a present embodiment of the water treatment system and method of the present invention generally designated by reference numeral 10 is shown.

[0043] exist figure 1 , a basic flow diagram of an innovative water treatment system 10 using stripping gas deoxygenation described below is shown, which allows a ship to treat water being transported from one port area to another while providing erosion inhibition. water. More particularly, the water treatment system 10 using stripping gas deoxygenation has a water intake mechanism 12 for supplying water into the ship from the outside. The water is then pumped via a pump mechanism such as, but not limited to, a ballast pump 14 , such as on a venturi injector, into the inlet port of the injector mechanism 16 . Oxygen stripping gas obtained from stripping gas source 18 is delivered to the inlet port of injector mechanism 16, which is propelled by boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com