Method and apparatus for releasing metal-resin joint

A joint, metal technology, applied in the direction of solid waste removal, household components, applications, etc., can solve the problems of unsuitable composite materials, metal-resin joints, object damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (i) Fabrication of Sample 1

[0076] A steel plate having a thickness of 0.10 mm, a length of 50 mm, and a width of 30 mm was prepared. On one side of the steel plate, an adhesive (quick-drying adhesive G17 manufactured by Konishi Co., Ltd.) made of synthetic rubber dissolved in a solvent is coated, and a 50 mm long, 30 mm wide, and 2 mm thick steel sheet is placed on it. An acrylic sheet made of polymethyl methacrylate so that it is superimposed on the steel sheet. In this way, five similar samples 1a, 1b...1e having junctions of the steel plate and the acrylic plate were prepared.

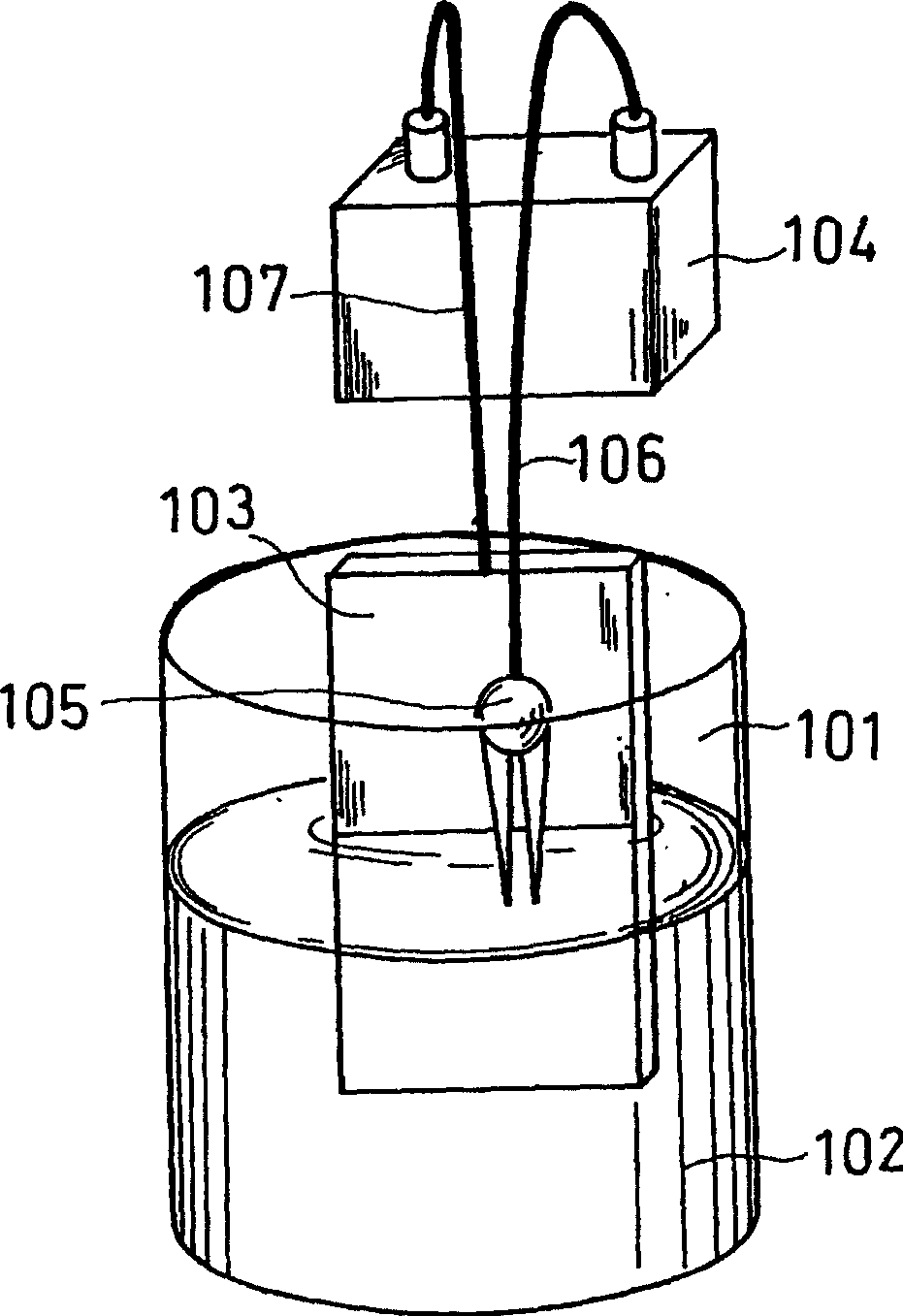

[0077] (ii) Assembly of the stripping device

[0078] First, five 100-ml beakers made of tetrafluoroethylene were prepared, and 100 ml of 0.01M, 0.1M, 3M, 7M, and 15M aqueous sodium hydroxide solutions (25° C.) were filled therein. These beakers are referred to as 2a, 2b, 2c, 2d and 2e, respectively. A nickel plate (50 mm in length, 30 mm in width, and 0.5 mm in thickness) as a counter...

Embodiment 2

[0091] Then, four sets of devices identical to those of the test device of sample 1d were fabricated. Then, at room temperature, the value of the electric current passed between the sample and the counter electrode was changed, and the change in the time required for peeling was checked. The results are shown in Table 2 together with the potential of the metal part of the sample with respect to the standard hydrogen electrode.

[0092]

Current value (mA)

metal part relative to the standard hydrogen

Electrode Potential (V)

Time until confirmation of detachment

(h)

1

-1.10

6

10

-1.23

4

100

-1.37

3.5

500

-1.61

3.5

800

-1.81

3.5

1000

-1.94

3.5

[0093] At a current value of 1 mA, although generat...

Embodiment 3

[0096] Five sets of devices identical to the test device of sample 1d were produced. Then, the beakers were immersed in hot water baths of various temperatures, and the peeling test of the metal-resin junction of the samples was performed in aqueous sodium hydroxide solutions of various temperatures. The current value passed between the metal portion of the metal-resin junction and the counter electrode was 10 mA.

[0097] For the three samples, the temperature of the hot water bath was set to 25°C, 45°C, and 65°C, respectively, and the same peeling test as in Example 1 was performed.

[0098] For one sample, the beaker was immersed in an ultrasonic cleaner (40 kHz, output 200 W) filled with 25° C. water, and the same peeling test as in Example 1 was performed.

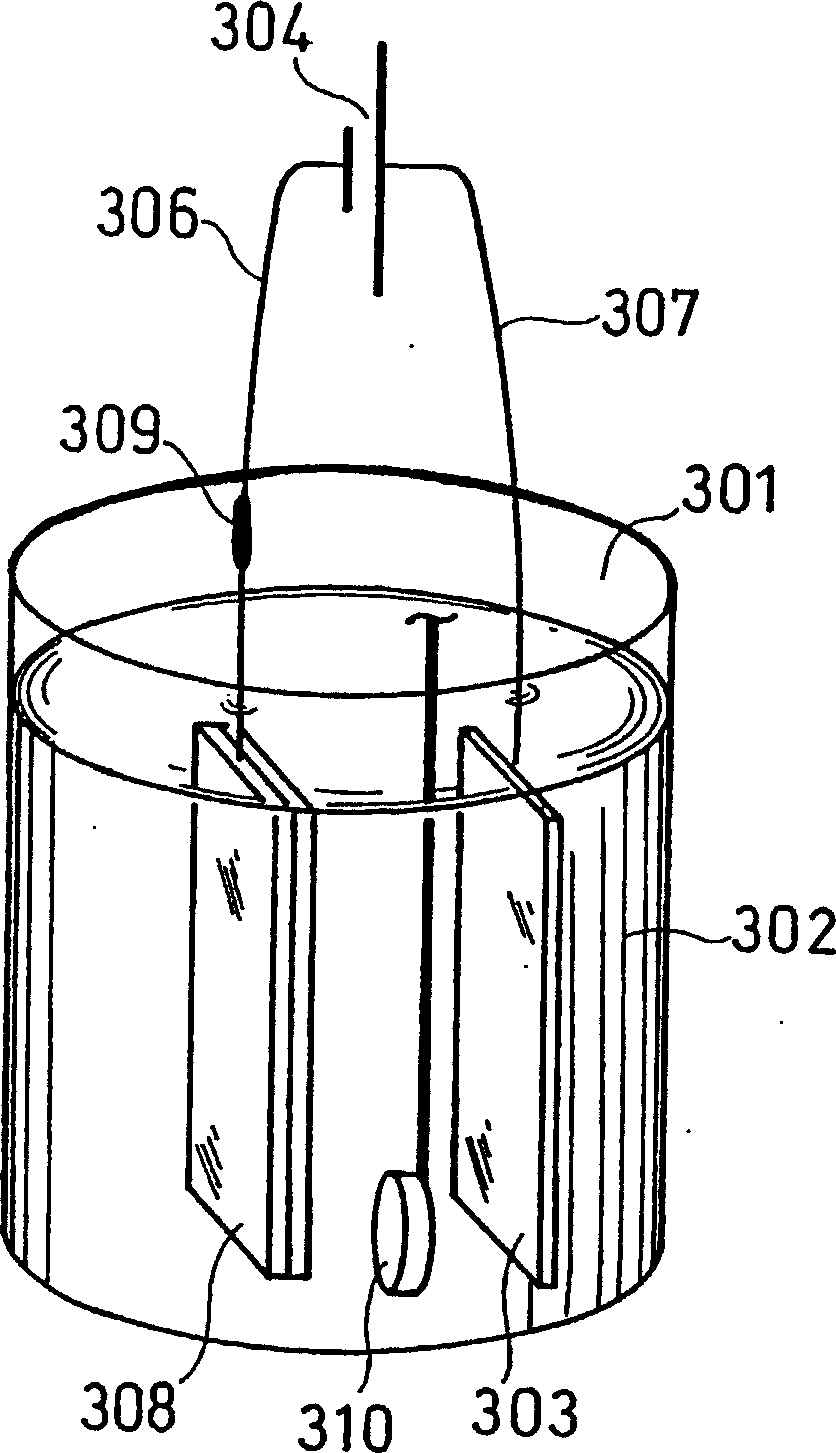

[0099] The remaining one sample was processed as follows. Its floor plan is shown in Figure 4 . also, Figure 4 The I-I line section diagram in Figure 5 .

[0100] First, an ear portion 402 also made of a ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com