Laminate for printing, printing method and printed matter using the same

一种层压体、下层的技术,应用在印刷的后处理、印刷、分层产品等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0083]Into a four-neck flask equipped with a stirring device, a thermometer, an inert gas inlet, and a condenser, 1000 parts of n-butyl acetate was added, and the temperature was raised to 110°C. Then at 110°C, 650 parts of methyl methacrylate, 245 parts of n-butyl methacrylate, 100 parts of 2-hydroxyethyl methacrylate, 5 parts of methacrylic acid, 15 parts of tert-butyl were added dropwise within 4 hours. base peroxy 2-ethylhexanoic acid ester, after the dropwise addition, the temperature was kept at 110° C. to continue the reaction for 6 hours to obtain a vinyl copolymer (a-1) with a non-volatile content of about 50%. The vinyl copolymer (a-1) was dried, and the SP value was measured to be 10.16.

[0084] (Reference example 2~6)

[0085] Vinyl copolymers (a-2) to (a-6) were obtained in the same manner as in Example 1 except that the ratio of the vinyl monomers was changed as shown in Table 1. The results of further drying and measuring SP are shown in Table 1.

[0086] ...

Embodiment 1

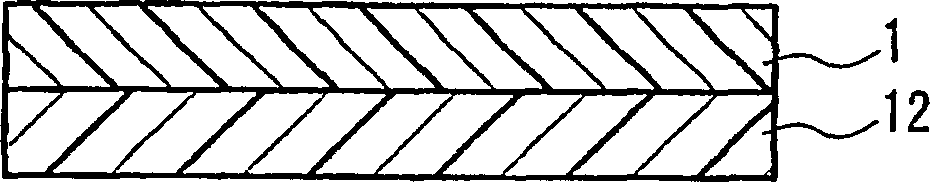

[0165] For example figure 1 When preparing the resin composition for the surface resin layer 1 shown, about 100 parts by weight of hexafluoropropylene / ethyl vinyl alcohol / VEOVA9 / adipic acid mono- Copolymer solution of vinyl ester=50 / 15 / 20 / 15 (weight ratio) ("VEOVA9": trade name manufactured by Japan Epoxy Resin Co., Ltd., vinyl ester of branched chain fatty acid, solvent is toluene / n-propanol=70 / 30 weight ratio mixed solvent, non-volatile content about 50%), about 7.4 parts of sorbitan polyglycidyl ether with an epoxy equivalent of 170, about 0.6 part of diazabicyclooctane, about 1 part of TINUVIN 900 (manufactured by Ciba Specialty Chemicals Inc., benzotriazole UV absorber), about 1 part of TINUVIN 292 (manufactured by Ciba Specialty Chemicals Inc., hindered amine light stabilizer) resin composition coated on the polyester film , and heat-dried at about 140° C. for about 10 minutes to make a dry film thickness of about 20 μm to obtain a surface resin layer 1 . Then, on the...

Embodiment 2

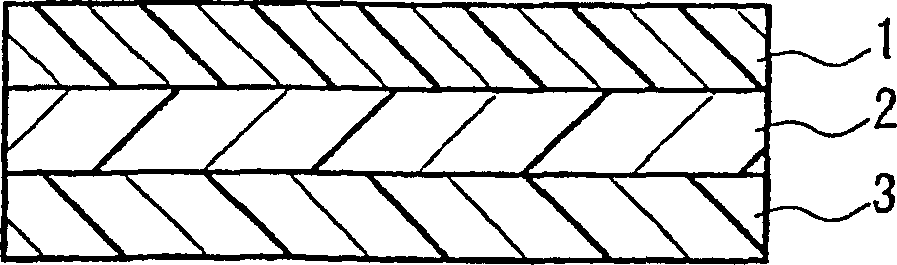

[0168] For example figure 2 When preparing the resin composition for the surface resin layer 1 shown, FLUONATE K-703 (manufactured by Dainippon Ink Chemical Industry Co., Ltd., weight average molecular weight 40000, solid component hydroxyl value 72, non-volatile component about 60%) was used. BURNOCK DN-950 is used as hardener and TINUVIN 292 is used as antioxidant. In Example 2, the mixing ratio of the resin composition for the surface resin layer 1 is about 100 parts for FLUONATE K-703, about 25 parts for BURNOCK DN-950, about 1 part for TINUVIN 900, and about 1 part for TINUVIN 292 . Then, the aforementioned composition was coated on a polyester film, and heated and dried at about 140° C. for about 10 minutes to obtain a dry film thickness of about 20 μm to obtain a surface resin layer 1 . Then use polycarbonate non-yellowing type polyurethane resin NY-331 (manufactured by Dainippon Ink Chemical Industry Co., Ltd., about 25% of non-volatile components, solvent DMF, abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com