Method for preparing light aggregate through burning fly ash by using garbage

A waste incineration fly ash and lightweight aggregate technology, applied in the direction of solid waste removal, sustainable waste treatment, solid waste management, etc., can solve the problem of quality decline of sintered products, affecting the effect of secondary pollution control, and dioxin control Difficulties and other problems, to achieve the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

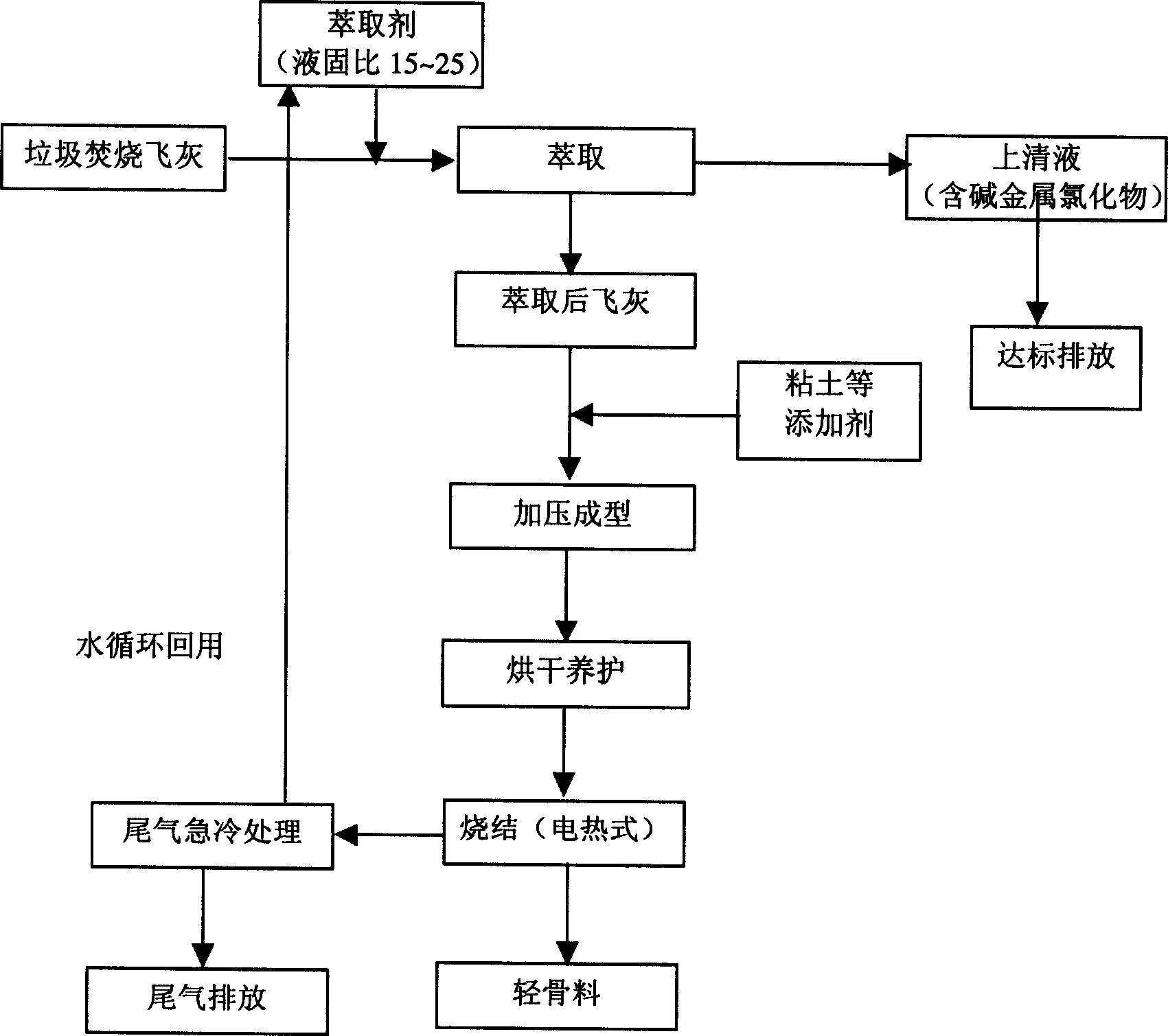

Method used

Image

Examples

example 1

[0030] Fly ash collected by a grate-type garbage incinerator bag filter in Shanghai was extracted with 15 times of water for 60 minutes. The kneading molding equipment produces cylindrical particles with a diameter of 20mm and a length of about 20mm, and enters the integrated electric heating sintering furnace for curing and sintering for about 8 hours. The temperature in the sintering zone is 1100°C. The material coming out of the sintering furnace is light aggregate with a density of 880kg. / m3, the compressive strength is 15.5Mpa, and the mechanical strength and pollutant indicators such as heavy metals all meet the requirements of building lightweight aggregate. The decomposition rate of dioxin in the fly ash reaches 98%. The leaching test of the product shows that the heavy metal meets the relevant standards, and the wastewater and waste gas discharged during the whole process meet the requirements of relevant regulations.

example 2

[0032] The fly ash collected by a grate-type garbage incinerator bag filter in Shanghai was extracted with 25 times of water for 45 minutes. The kneading molding equipment produces cylindrical particles with a diameter of 10mm and a length of about 10mm, and enters the integrated electric heating sintering furnace for curing and sintering for about 7 hours. The temperature in the sintering zone is 1080°C. The material coming out of the sintering furnace is light aggregate with a density of 900kg. / m3, compressive strength 14.6Mpa, mechanical strength and pollutant indicators such as heavy metals all meet the requirements of building lightweight aggregate. The decomposition rate of dioxin in the fly ash reaches 98%. The leaching test of the product shows that the heavy metal meets the relevant standards, and the wastewater and waste gas discharged during the whole process meet the requirements of relevant regulations.

example 3

[0034] The fly ash collected by a grate-type garbage incinerator bag filter in Shanghai was extracted with 25 times of water for 45 minutes. The kneading molding equipment produces cylindrical particles with a diameter of 10mm and a length of about 10mm, and enters the integrated electric heating sintering furnace for curing and sintering for about 9 hours. The temperature in the sintering zone is 1000°C. The material coming out of the sintering furnace is light aggregate with a density of 880kg. / m3, the compressive strength is 14.0Mpa, and the mechanical strength and pollutant indicators such as heavy metals all meet the requirements of building lightweight aggregate. The decomposition rate of dioxin in the fly ash reaches 98%. The leaching test of the product shows that the heavy metal meets the relevant standards, and the wastewater and waste gas discharged during the whole process meet the requirements of relevant regulations.

[0035] Compared with the existing waste inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com