Release controlled coated fertilizer and its composition and preparation method

A technology for controlled-release fertilizers and fertilizers, which is applied in fertilizer mixtures, fertilizer forms, and fertilization devices, etc., can solve the problems of high cost, cumbersome process, and excessive film thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

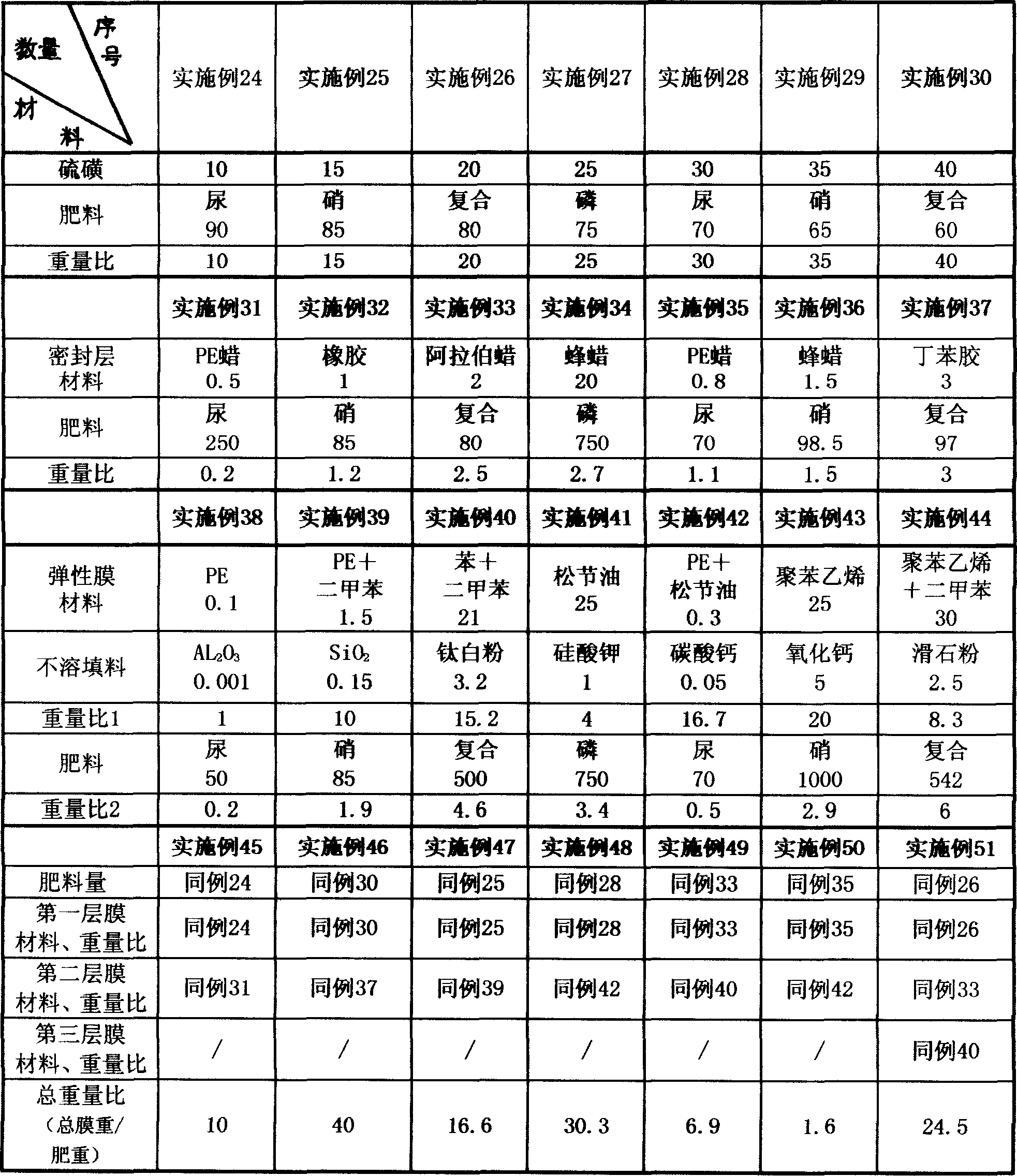

Examples

Embodiment 1

[0065] Embodiment 1: monolayer film

[0066] Weigh 36 parts of urea granule fertilizer as the core, weigh 4 parts of sulfur, heat to 150°C, and melt slowly. On the granular urea, a coated urea fertilizer is obtained; after drying, the weight of the coated layer is 10% of the total weight of the coated fertilizer.

Embodiment 2

[0067] Embodiment 2: monolayer film

[0068] Take 60 parts of compound fertilizer as the core, weigh 40 parts of sulfur, heat to 165 ° C, and slowly melt, after all of them are melted into liquid, use compressed air to spray the spray liquid on the granular fertilizer with a sprayer to obtain A layer of coated compound fertilizer; after drying, the weight of the coated layer is 40% of the total weight of the coated fertilizer.

Embodiment 3

[0069] Embodiment 3: monolayer film

[0070] Weigh 28 parts of diammonium phosphate as the core, weigh 7 parts of sulfur, heat to 130°C, and melt slowly. After all of them are melted into liquid, spray the spray liquid on the granular urea with a sprayer using compressed air , to obtain coated urea fertilizer; after drying, the weight of the coated layer is 20% of the total weight of the coated fertilizer.

[0071] Effect: Weigh 100 grams of uncoated common urea in this example and put it into 1000 milliliters of water for dissolution test. At the same time, weigh 100 grams of coated urea prepared in this embodiment of the present invention, put it into 1000 milliliters of water under the same room temperature condition, and measure the urea concentration in water after different time. The results show that the time for the coated urea of the present invention to completely dissolve is 29,000 times longer than that of ordinary urea.

[0072] Field tests show that compared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com