Member for semiconductor device

A semiconductor and device technology, applied in the field of semiconductor devices, can solve the problems of low resin bonding strength, inability to achieve resin bonding strength, insufficient bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

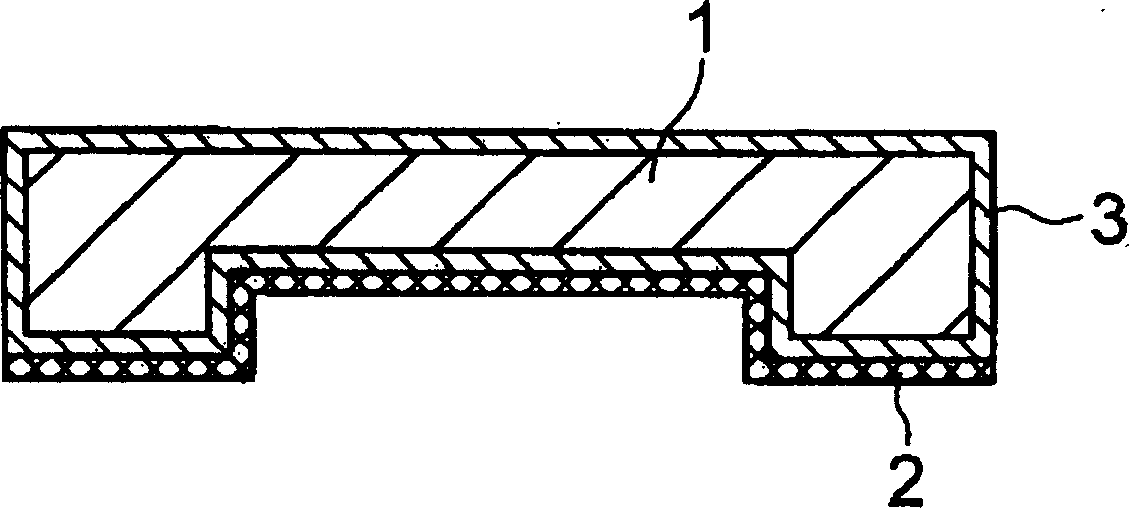

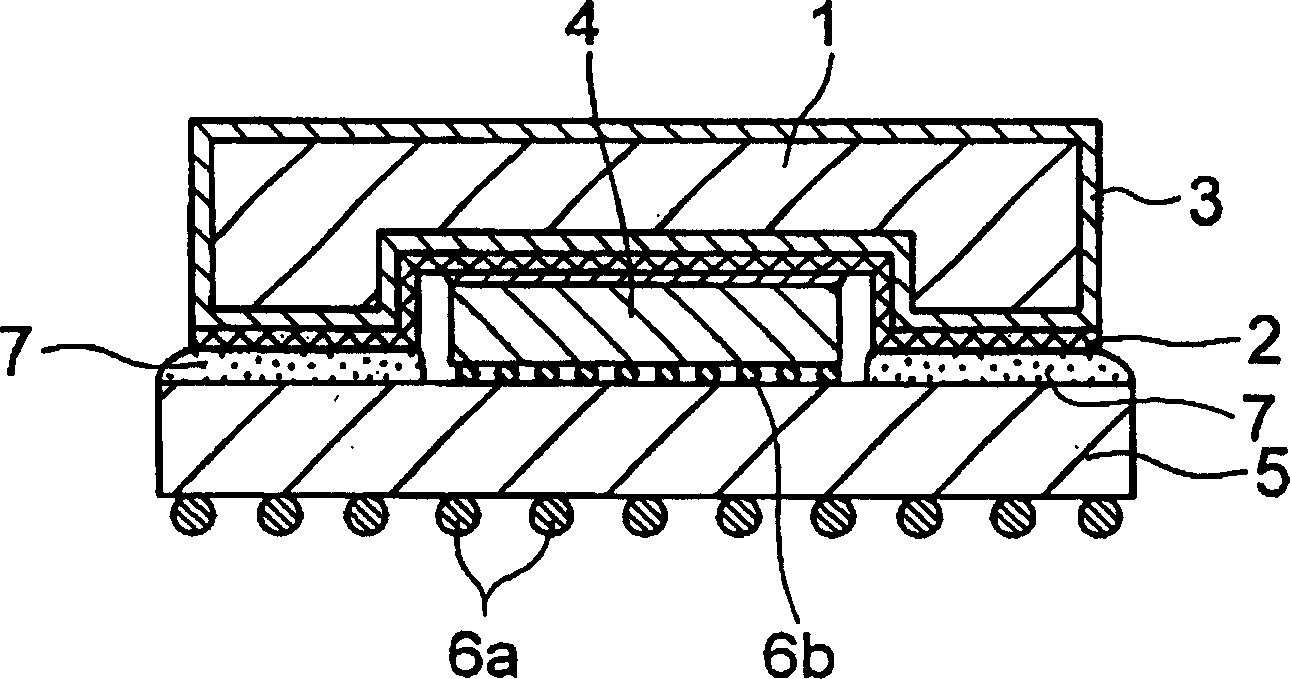

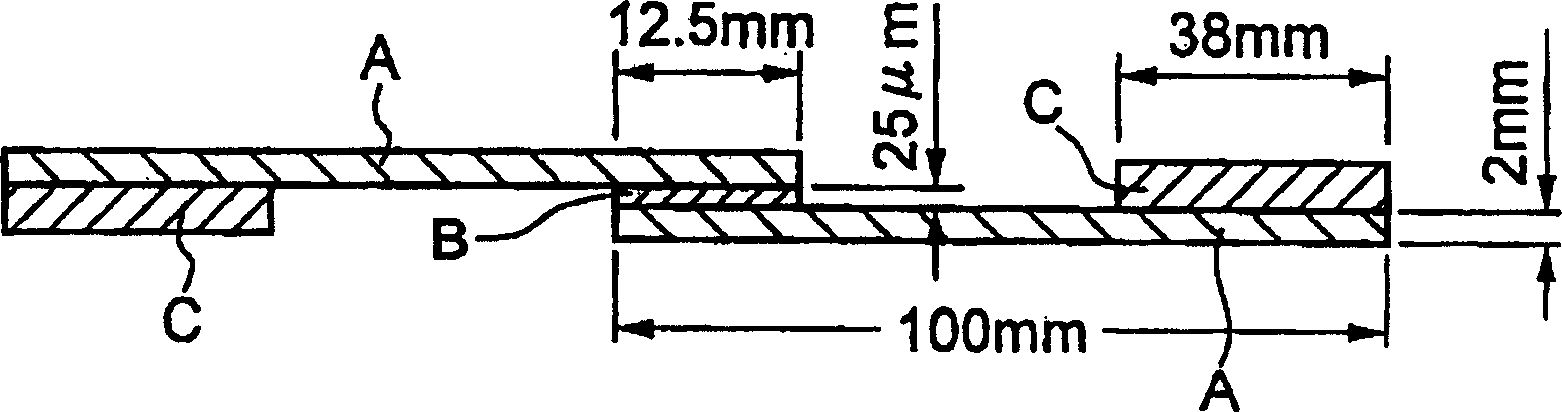

[0026] According to the present invention, the basic parts of parts used in semiconductor devices are made of alloys or composites mainly containing Cu and W and / or Mo, alloys or composites mainly containing Al-SiC, and alloys or composites mainly containing Si-SiC become. These alloys or composites have thermal expansion coefficients close to those of semiconductor components and packaging materials, and have excellent thermal conductivity. According to the present invention, when a part for a semiconductor device including a basic part made of these alloys or composites is bonded with other parts, such as a package, with resin, at least one surface of said basic part to be bonded by resin is provided A coating made of a thin film of solid carbon particles so that the bond strength of the resin can be increased.

[0027] The solid carbon particle film is amorphous carbon called diamond-like carbon, amorphous carbon, i-C or DLC (diamond carbon). Films of solid carbon particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com