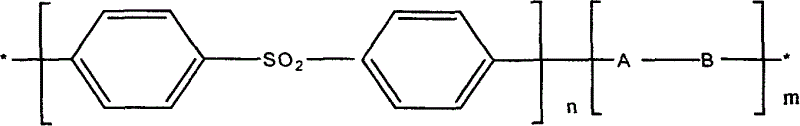

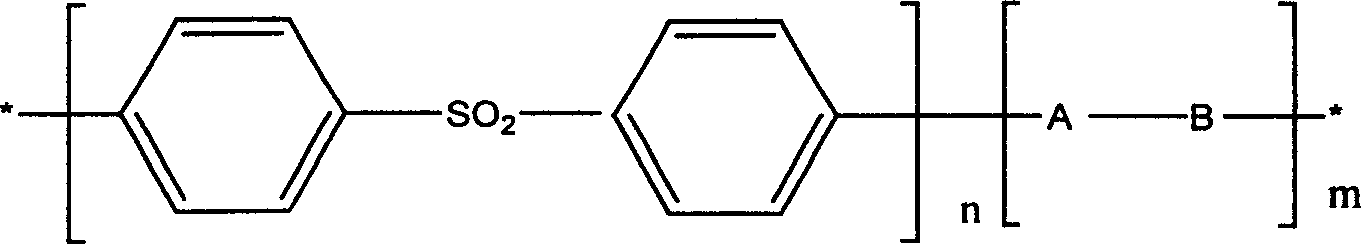

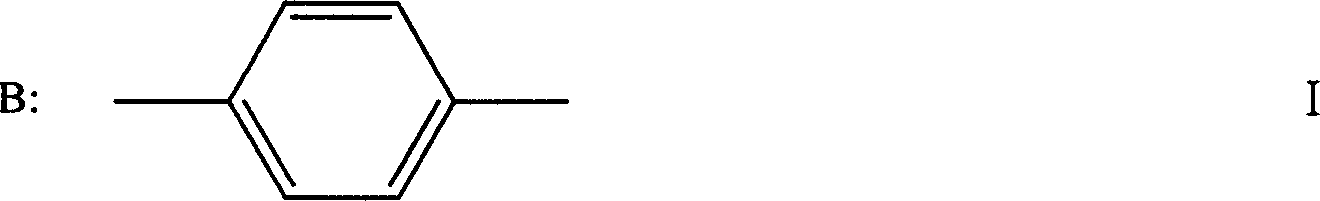

Aqueous polyarylethersulphones dispersion liquid and process for preparing same

A technology of polyarylether sulfone and polyarylene ether sulfone, which is applied in the field of water-based polyarylether sulfone dispersion liquid and its preparation, can solve the problem of not completely water-based, low content of polyarylene ether sulfone, and unfavorable environmental protection and other issues to achieve the effect of avoiding pollution and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Thoroughly mix 240ml of chloroform with 30ml of methanol, dissolve 4g of polyvinylpyrrolidone (PVP) in the above solution, and dissolve 140g of polyethersulfone in the above mixed solution to prepare a polyethersulfone solution.

[0035] Dissolve 8g of sodium dodecylbenzenesulfonate in 280ml of deionized water; pour the aqueous solution of sodium dodecylbenzenesulfonate into the colloid mill, then slowly add the polyethersulfone solution into the colloid mill, disperse, and obtain poly ether sulfone emulsion.

[0036] Pour the prepared polyethersulfone emulsion containing organic solvent into a 1000 ml three-necked flask equipped with a stirring device and a condensing device, heat it in a water bath, and control the temperature at 55°C for 3 hours and 65°C for 3 hours until no solvent evaporates , and then heated to 85 ° C for 30 minutes. Stop stirring and stop heating to obtain a water-based polyethersulfone dispersion.

Embodiment 2

[0038] Thoroughly mix 240ml of chloroform and 20ml of methanol, and dissolve 90g of polyethersulfone in the above mixed solution to prepare a polyethersulfone solution.

[0039] Dissolve 8 g of sodium dodecylbenzenesulfonate in 280 ml of deionized water. . Pour the aqueous solution of sodium dodecylbenzenesulfonate into the colloid mill, then slowly add the polyethersulfone solution into the colloid mill, and disperse to prepare the polyethersulfone emulsion.

[0040] Pour the prepared polyethersulfone emulsion containing organic solvent into a 1000 ml three-necked flask equipped with a stirring device and a condensing device, heat it in a water bath, and control the temperature at 55°C for 3 hours and 65°C for 3 hours until no solvent evaporates , and then heated to 85 ° C for 30 minutes. Stop stirring and stop heating to obtain a water-based polyethersulfone dispersion.

Embodiment 3

[0042] Thoroughly mix 240ml of chloroform and 10ml of methanol, and dissolve 90g of polyethersulfone in the above mixed solution.

[0043] Dissolve 6 g of sodium dodecylbenzenesulfonate in 280 ml of deionized water. Pour the sodium dodecylbenzenesulfonate aqueous solution into the colloid mill, then slowly add the polyethersulfone solution into the colloid mill for dispersion.

[0044] Pour the prepared polyethersulfone emulsion containing an organic solvent into a 1000 ml three-neck flask equipped with a stirring device and a condensing device, and heat it in a water bath. The temperature control range is 55°C for 2 hours, and 65°C for 3 hours until no solvent evaporates. Then, the temperature was raised to 80°C for 30 minutes. Stop stirring and stop heating to obtain a water-based polyethersulfone dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com