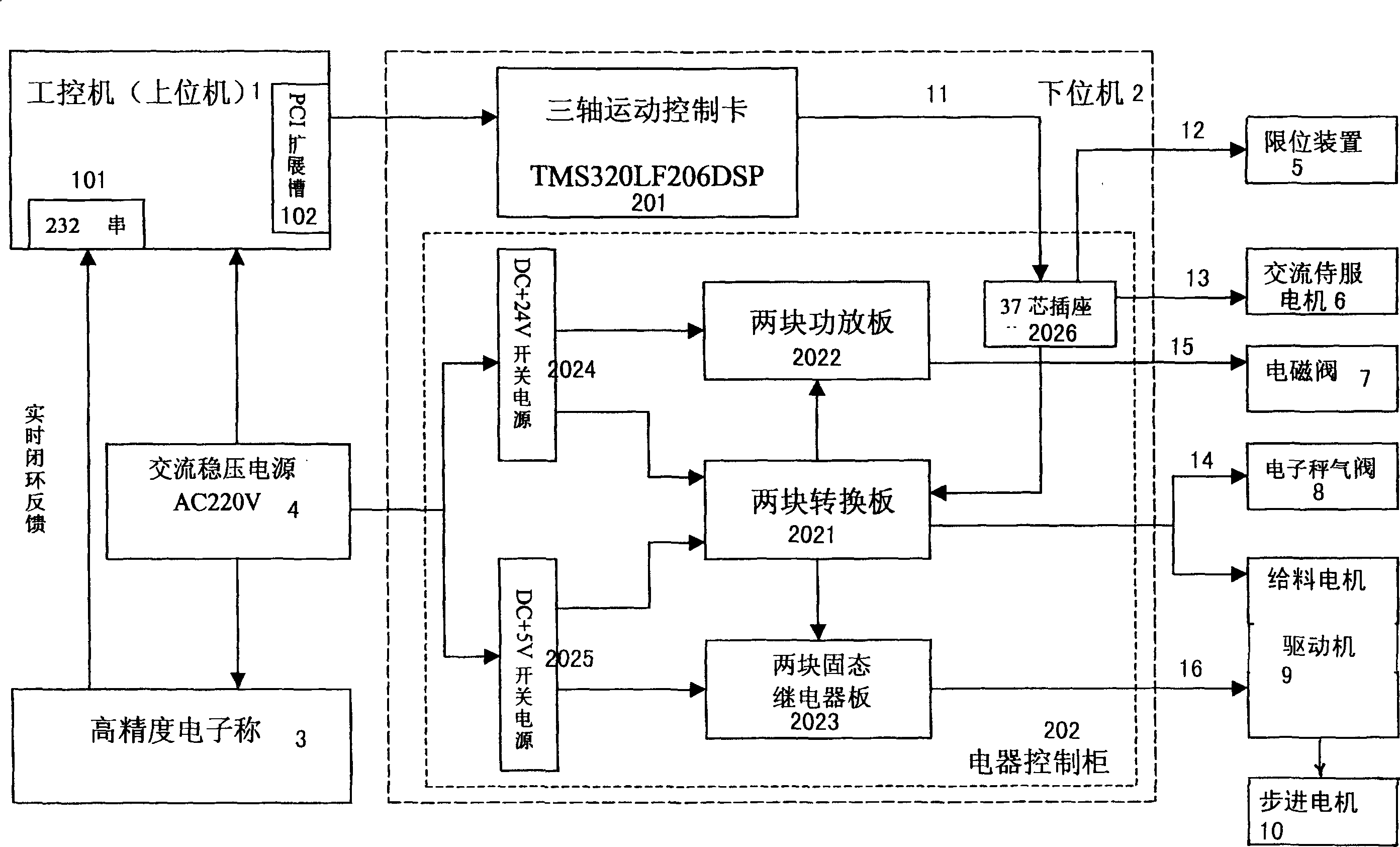

Circuit system for automatic material weighing and blending production line control

A technology for control circuits and production lines, applied in general control systems, control/regulation systems, non-electric variable control, etc. Low-level problems, to achieve the effect of novel design ideas, energy saving and equipment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

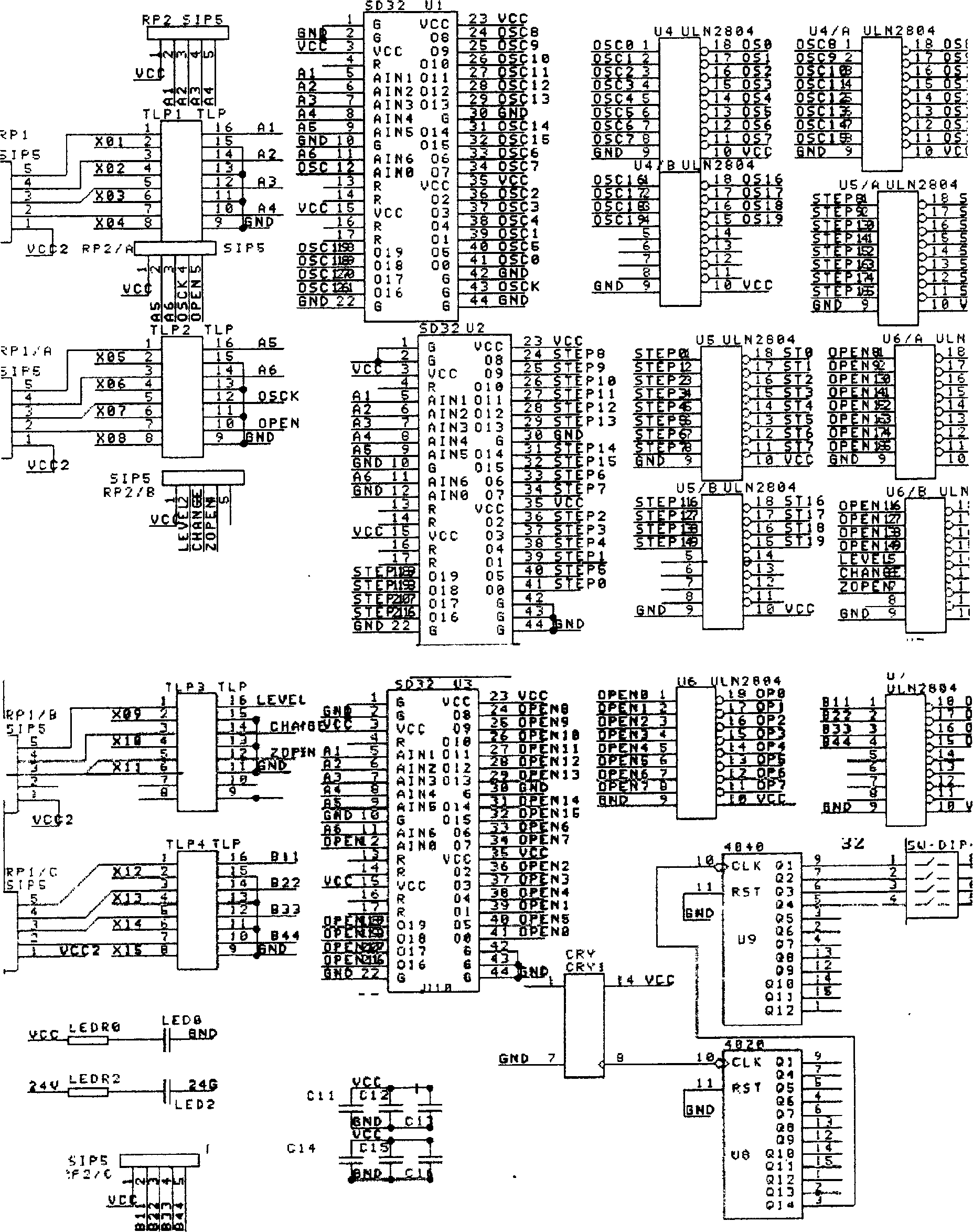

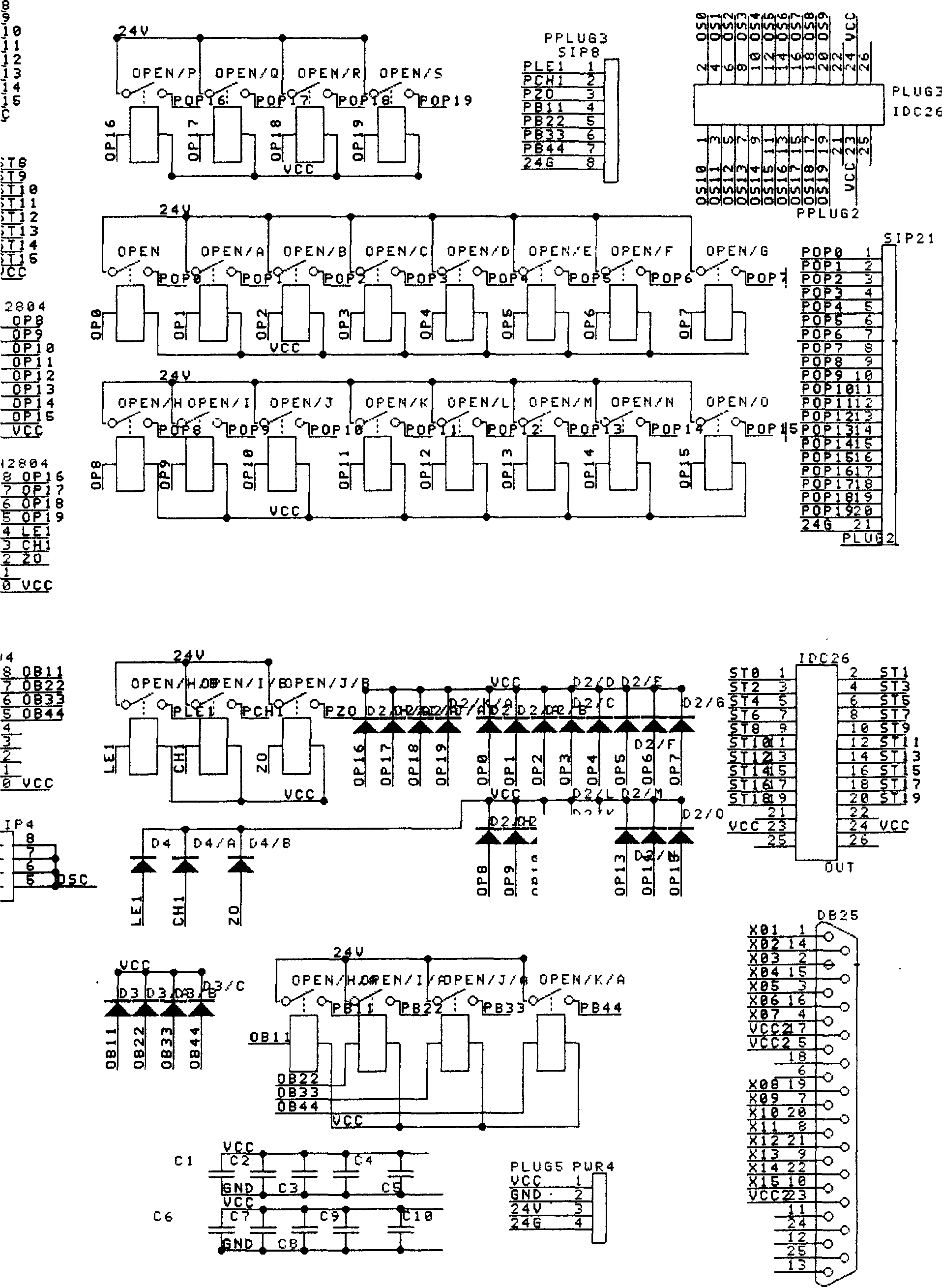

[0022] The invention is a control system capable of realizing high-precision and large-scale automatic batching and weighing, and establishes a dynamic ratio model for the differences in dye specific gravity, particle size, flow rate and drop size of various dyes. On the basis of solving the dynamic weighing accuracy, the network real-time multi-task control technology is applied to form a dynamic weighing and automatic batching production line of 20-100 kinds of materials. Using adaptive control algorithm, according to the specific gravity and particle size of various dyes, the corresponding final drop control time is established, and according to the real-time closed-loop feedback of high-precision scales, accurate weighing is finally realized. The weighing range of each dye is between 0.1g-32kg, the minimum resolution is between 0.01-0.1g, and the weighing accuracy is ≤1%. The system is equipped with a sample debugging system and a production system, both of which can compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com