Nontoxic whole-degradable plastics and process for making same

A fully degradable plastic technology, applied in the field of non-toxic fully degradable plastics and its preparation, can solve the problems of not meeting the technical requirements of fully degradable, slow degradation, affecting material development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

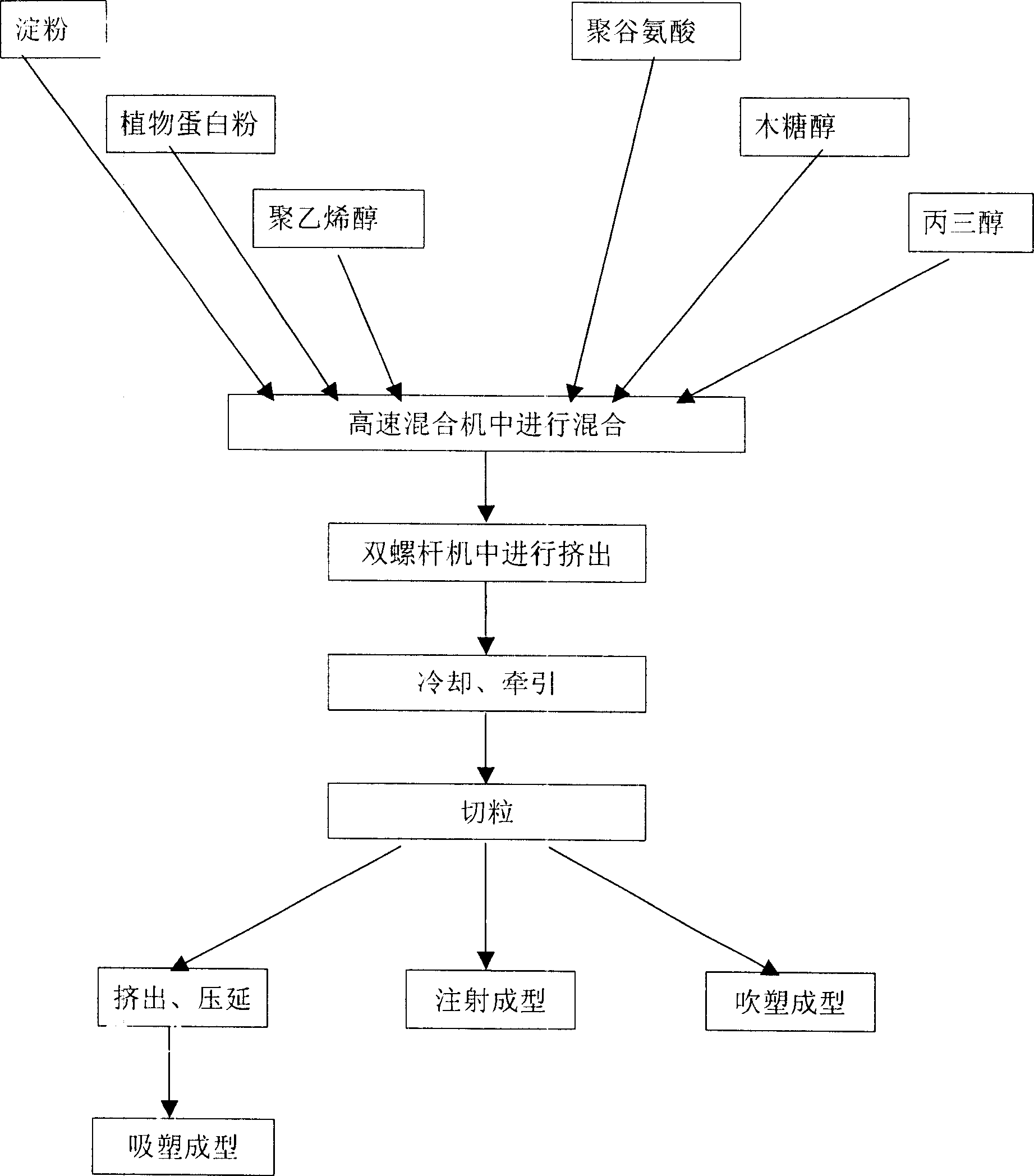

Image

Examples

Embodiment 1

[0016] a. Add starch, vegetable protein powder, polyvinyl alcohol, polyglutamic acid, xylitol, and glycerol into a high-speed mixer, and stir and mix evenly at room temperature. The proportioning of each added component is: 50 parts of starch, 5 parts of vegetable protein powder, 15 parts of polyvinyl alcohol, 10 parts of polyglutamic acid, 5 parts of xylitol and 8 parts of glycerin.

[0017] b. Add the above-mentioned components to the twin-screw extruder, heat and extrude in the twin-screw extruder. The heating of the twin-screw extruder is carried out in the barrel, and the heating is carried out by segmental temperature control. The temperature of each segment is 100°C, 125°C, 150°C, 160°C, 120°C, and 120°C.

[0018] c. The material extruded from the die head is cooled, dragged and granulated to form fully degradable plastic pellets.

[0019] d. The above-mentioned fully degradable plastic pellets can also be made into sheets by an extrusion molding machine at a temperatu...

Embodiment 2

[0023] The ratio of the added components can also be: 60 parts of starch, 10 parts of vegetable protein powder, 20 parts of polyvinyl alcohol, 10 parts of polyglutamic acid, 8 parts of xylitol, and 12 parts of glycerol.

[0024] The non-toxic and fully degradable plastic pellets obtained through the process of the present invention, as well as various degradable plastic products obtained through general plastic molding processing methods, have the particularity of performance and the universality of plastic molding processing Combined and less expensive. These advantages and characteristics create favorable conditions for its popularization and use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com