Non-grid ion plating aide

A plating aid and ion technology, applied in ion implantation plating, ion beam tube, sputtering plating, etc., can solve the problems of reduced roughness, increased refractive index, and reduced water absorption, and achieves easy anode replacement , good quality, easy to disassemble and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the drawings and embodiments.

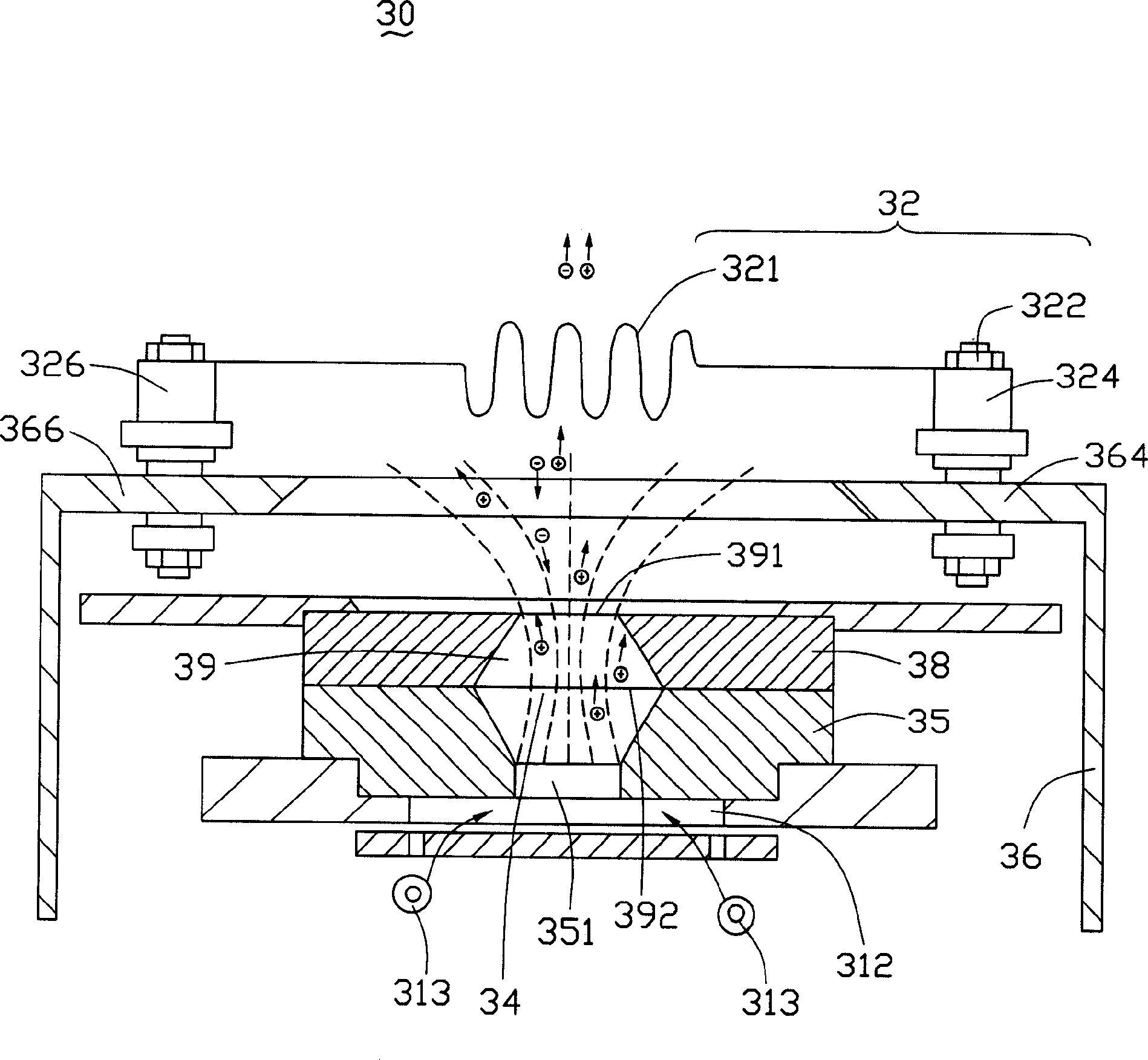

[0020] See figure 2 , A gridless ion plating aid of the present invention includes: an ion source 30, the ion source 30 includes: a discharge area 34 (also called a discharge chamber); a magnetic circuit 36, the magnetic circuit 36 surrounding the Discharge area 34; a gas supply system (not labeled); an anode 35 arranged below the discharge area 34; a cathode 32 arranged above the discharge area 34, corresponding to the anode 35; and an anode emitting The angle workpiece 38 is arranged above the anode 35 for controlling the ion emission angle.

[0021] The magnetic circuit 36 of the present invention is arranged around the gridless ion booster, and is generally composed of a back magnetic pole (not labeled), a magnet (not labeled), an outer magnet (not labeled), and top magnets 364 and 366. The back magnetic pole (not labeled), magnet (not labeled), outer ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com