Battery equalization method and battery equalization circuit

A battery balancing and balancing technology, applied in battery circuit devices, secondary battery charging/discharging, circuit devices, etc., can solve the problems of increasing the weight and volume of balancing circuits, difficult integrated circuits, and the impact of battery pack output. The effect of integration, simplifying the circuit structure, and speeding up the equalization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

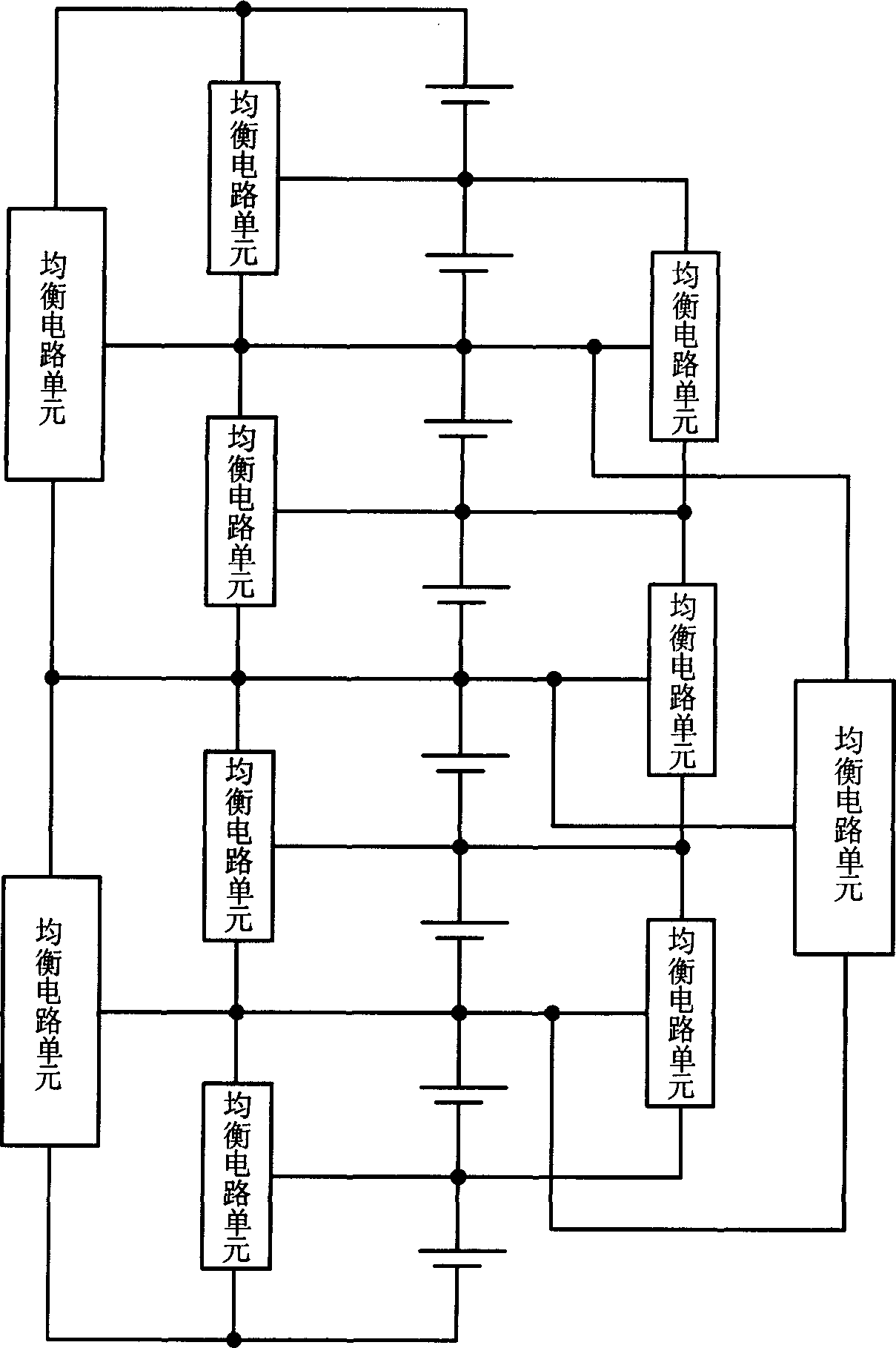

[0031] Embodiment one: see attached figure 1 to attach Figure 4 As shown, a battery balancing circuit is used to balance the power of a series battery pack composed of 8 lithium rechargeable batteries. It is composed of a two-stage battery balancing circuit structure, and a set of battery balancing circuits is set between every two adjacent batteries unit, which constitutes the first-level battery balancing circuit; a set of battery balancing circuit units are respectively set up for the 4 batteries at the negative end, the 4 batteries at the middle end, and the 4 batteries at the positive end to form the second-level battery balancing circuit, and each battery balancing circuit unit work independently.

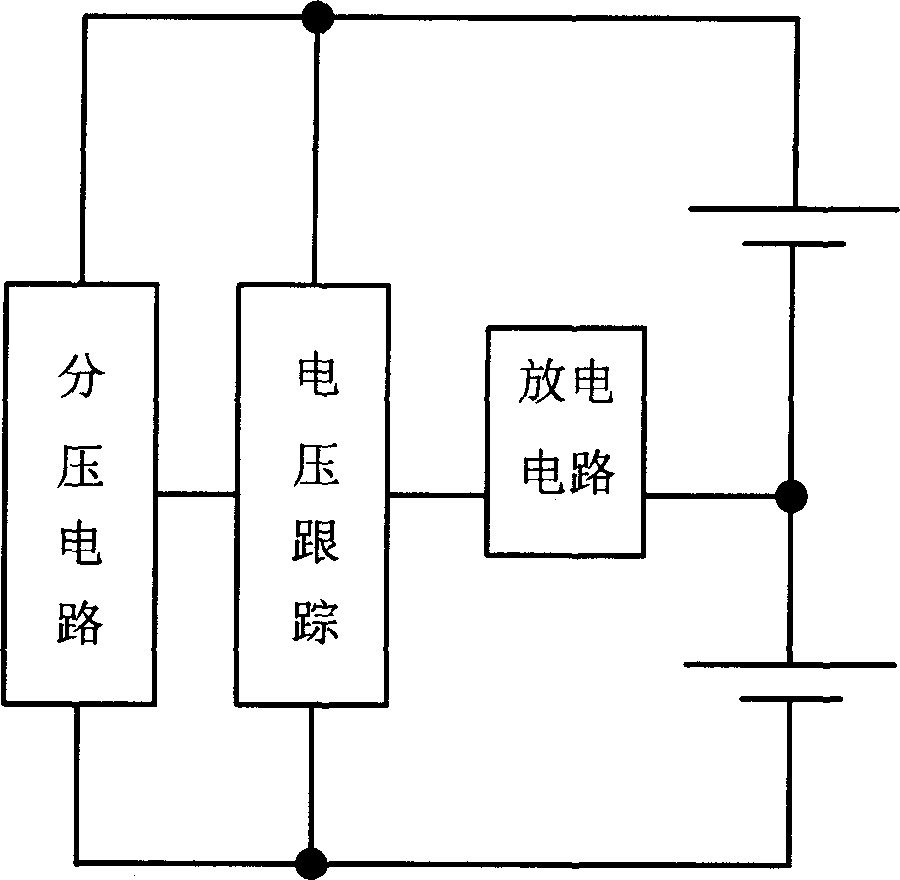

[0032] The battery equalization circuit unit of this embodiment includes a voltage divider circuit and a discharge circuit, and the voltage divider circuit is composed of a voltage divider resistor arranged between the positive terminal and the negative terminal of 2 or 4 b...

Embodiment 2

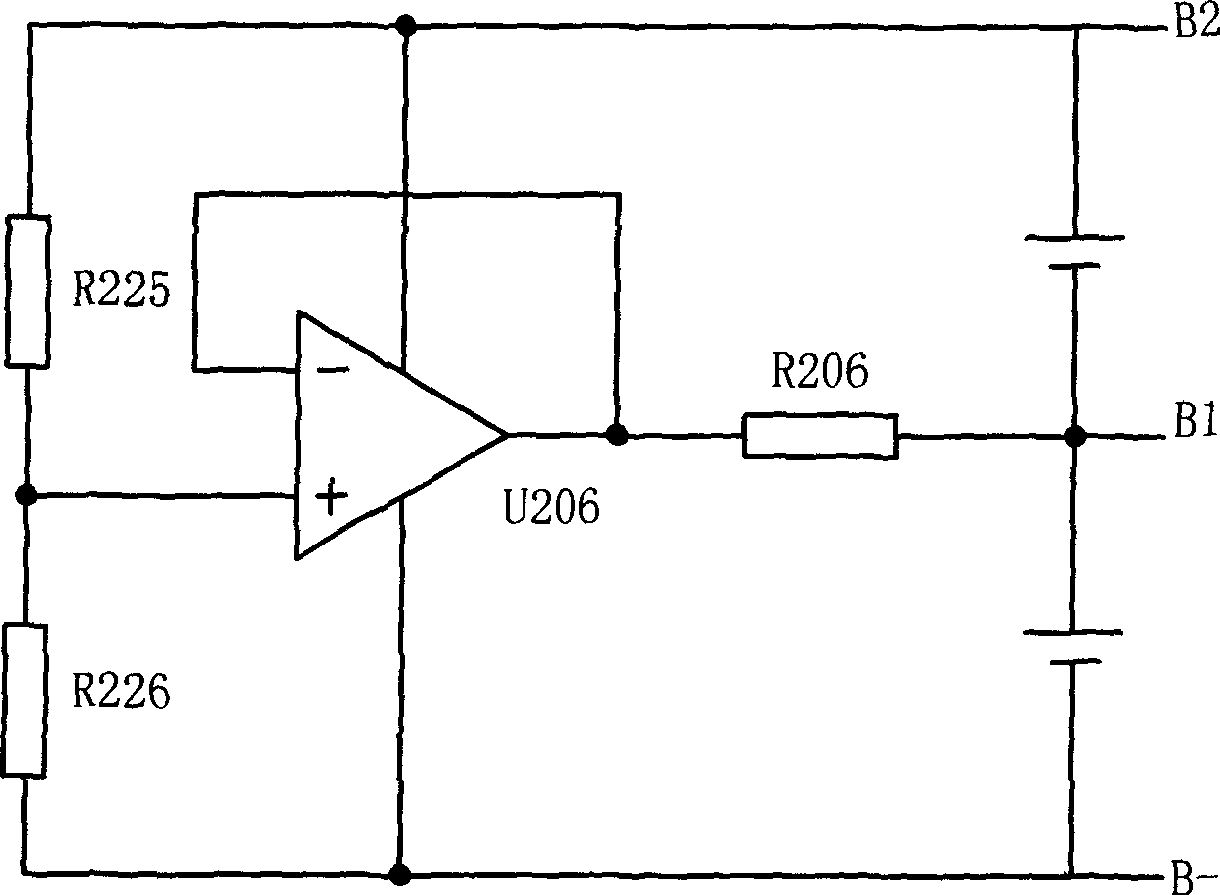

[0034] Embodiment two: see attached Figure 5 to attach Figure 7 As shown, a battery balancing circuit is used to balance the power of a series battery pack composed of 6 lithium rechargeable batteries, and a group of battery balancing circuit units are arranged between each adjacent two batteries, and the battery balancing circuit unit includes a voltage divider circuit, a first comparator, a first discharge switch connected between the positive terminal and the middle terminal of the battery pack and a first discharge resistor, a second comparator, a second discharge switch connected between the middle terminal and the negative terminal of the battery pack and the second discharge resistor; the positive phase input of the first comparator is connected to the middle value position of the voltage divider circuit, the negative phase input is connected to the middle terminal of the battery pack, and the output drives the first discharge switch; the positive phase of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com