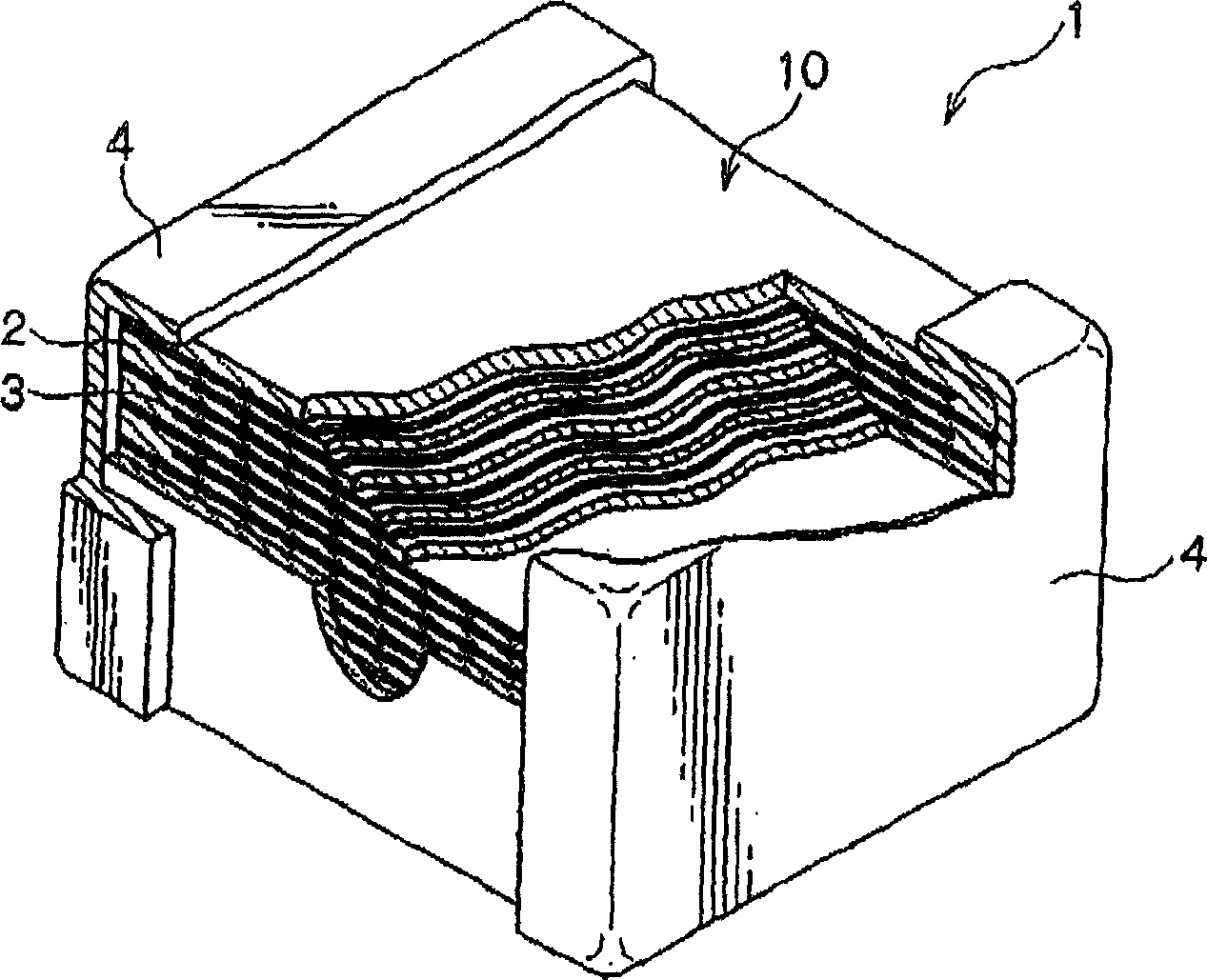

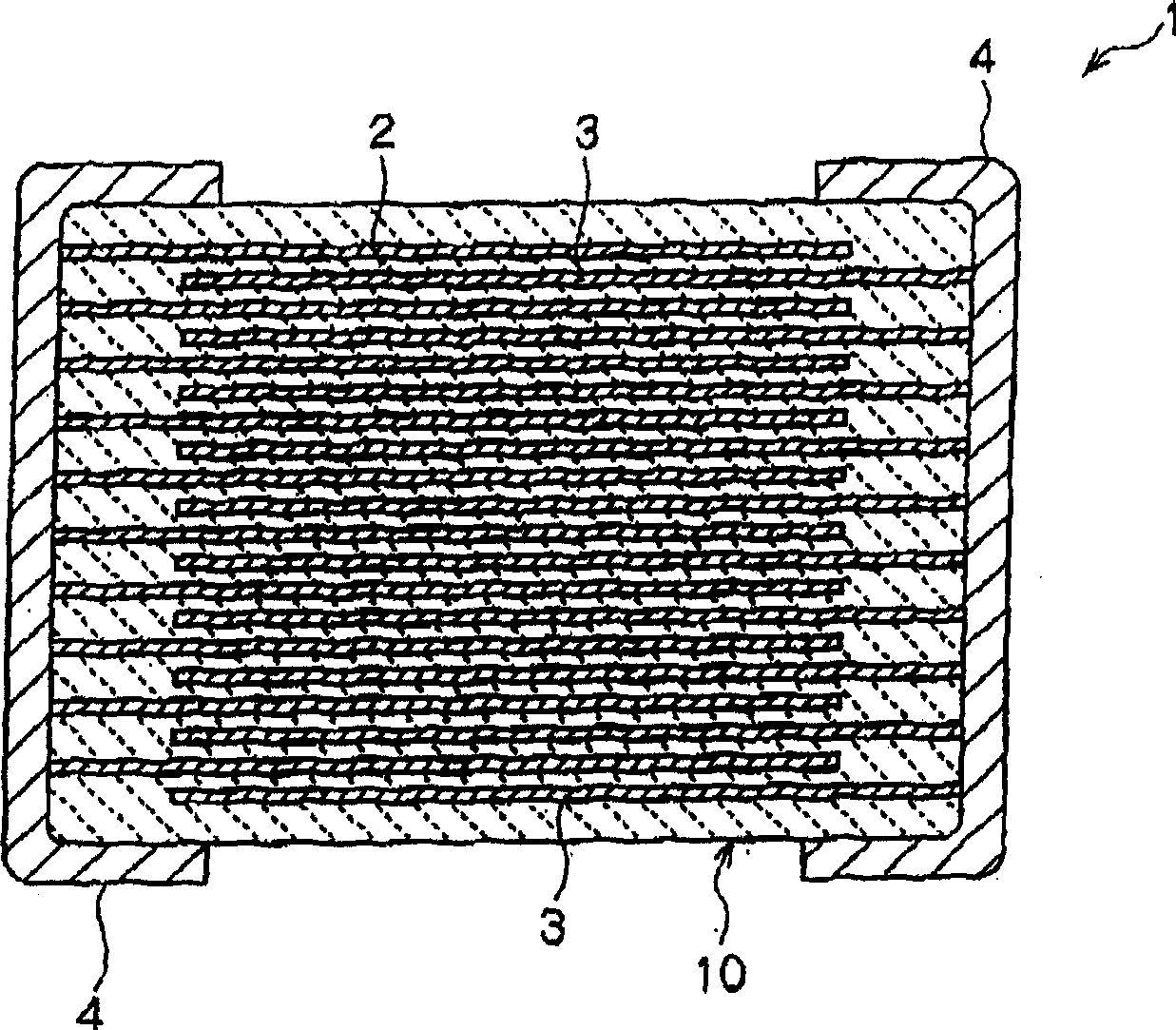

Dielectric ceramic composition, multilayer ceramic capacitor, and method for manufacturing the same

A technology of ceramic capacitors and dielectric layers, applied in the direction of multilayer capacitors, capacitors, fixed capacitors, etc., can solve problems such as inability to adapt to automotive electronic devices, high dielectric constant materials can not meet the X7R characteristics, etc., and achieve the effect of long failure life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] The present invention will be described in detail using the following examples and comparative examples. However, the present invention is not limited to the content described below.

[0130] (manufacturing of sample 1)

[0131] First, prepare the main component raw materials (BaTiO 3 ) and the first to seventh auxiliary component raw materials are used as starting materials for manufacturing dielectric materials. In addition, for the main component BaTiO 3 , and BaCO can also be weighed separately 3 and TiO 2 , use a ball mill to wet mix for about 16 hours, dry the mixture, and then use a ball mill to wet pulverize the fired product fired in the air at a temperature of 1100°C for about 16 hours, and the same result can be obtained by using the material obtained in this way . In addition, the main component BaTiO 3 It can be obtained by hydrothermal synthetic powder and oxalate method, and the same result can be obtained by using the substance obtained in this wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com