Process for preparing amorphous adefovir dipivoxil

An adefovir dipivoxil and amorphous technology, which is applied in the field of preparation of amorphous organic compounds, can solve the problems of low product purity, many AD impurities and high cost, and achieves the requirements of high purity, reduced temperature conditions, and reduced production. The effect of energy consumption and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

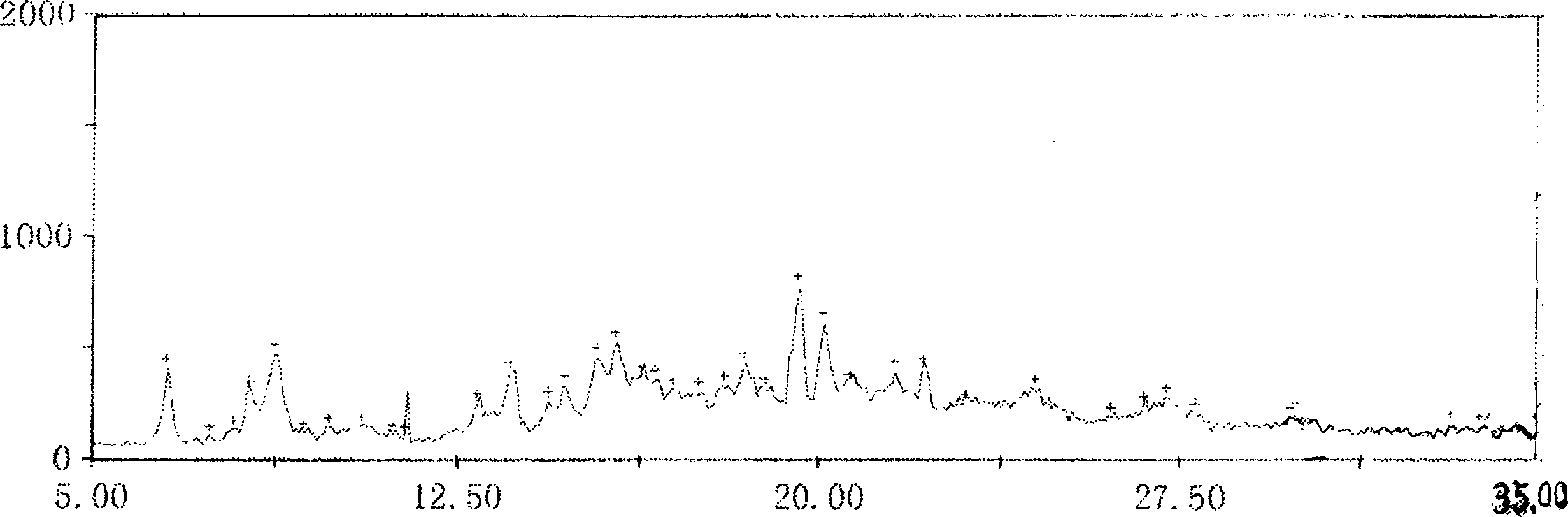

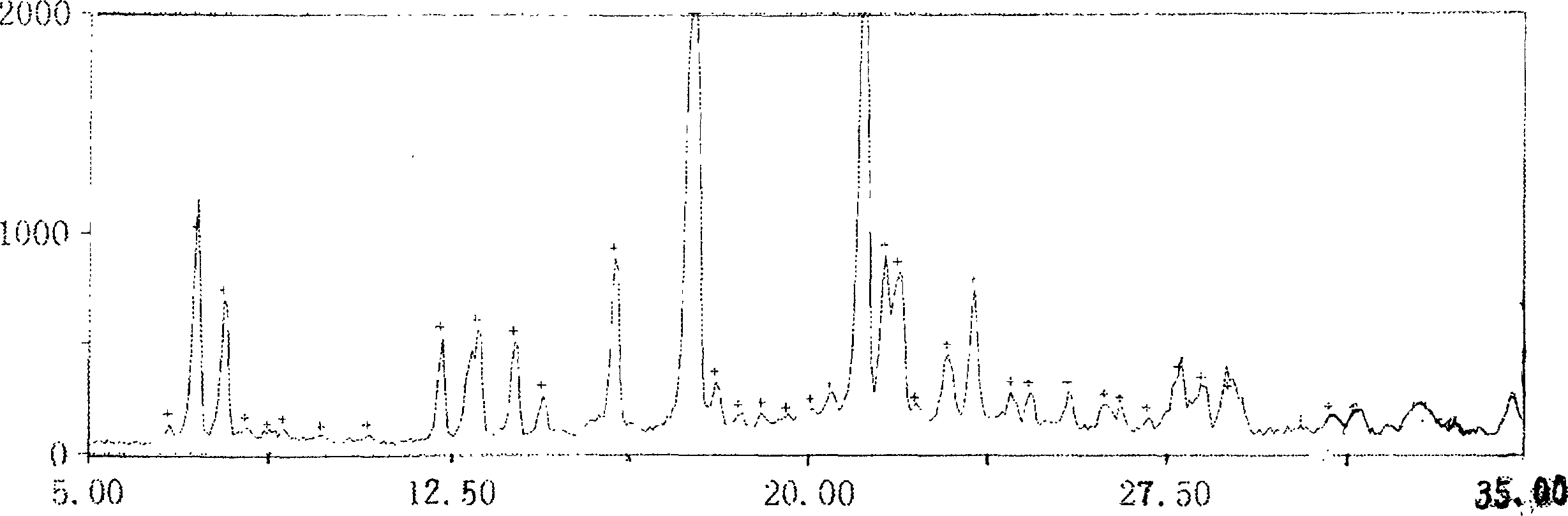

Image

Examples

Embodiment 1

[0063] AD crude product can be purchased from the market, and can also be prepared by the following methods:

[0064] Add 4g (0.05mol) PMEA (Adefovir) 2 In a three-necked round-bottomed flask, add 60ml of dry DMF, N-N' dicyclohexyl-4-morpholine 8.32g (0.029mol) and 11g chloromethyl pivalate in turn, stir for 15min, the mixture becomes homogeneous, and at 60 React at ℃ for 4 hours, heat to 60℃ and stir for 4 hours, cool down to 25℃, add 55ml of isopropyl acetate, stir for 30min, filter with suction, wash the filter cake twice with 5ml of isopropyl acetate, and wash the organic layer twice with 10ml of water , the aqueous layer was back-extracted twice with 5ml isopropyl acetate, combined the organic phases, distilled under reduced pressure to an oily substance, added an equal volume of ethanol to dissolve it, added 5 times the amount of water at 0°C, precipitated crystals, and filtered with suction , a white solid was obtained, and dried under reduced pressure to obtain crude ...

Embodiment 2

[0067] Weigh 50g of the crude AD raw material, fully dissolve it with 100ml of absolute ethanol, put it in the refrigerator at -5°C for 6 hours, then quickly add 800ml of -8°C butyl ether at this low temperature, and shake to form a white precipitate. and a suction filter bottle at a low temperature of -10° C. to obtain a white solid, which was vacuum-dried at room temperature to obtain 44 g of AD mainly in an amorphous form (amorphous form was 90%).

Embodiment 3

[0069] Weigh 50g of the crude AD raw material, fully dissolve it with 100ml of acetone, put it in the refrigerator, and freeze it at -2°C for 5 hours. The funnel and filter flask were filtered at -20°C to obtain a white solid, which was vacuum-dried at room temperature to obtain 45 g of AD (85% in amorphous form) with a purity of 98.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com