Lining structure of aluminium electrolytic bath

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of aluminum electrolytic cell lining structure, can solve problems such as side carbon block pressure plate deformation, liquid electrolyte infiltration, poor heat dissipation, etc., to achieve extended service life, good heat balance, increased The effect of large cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

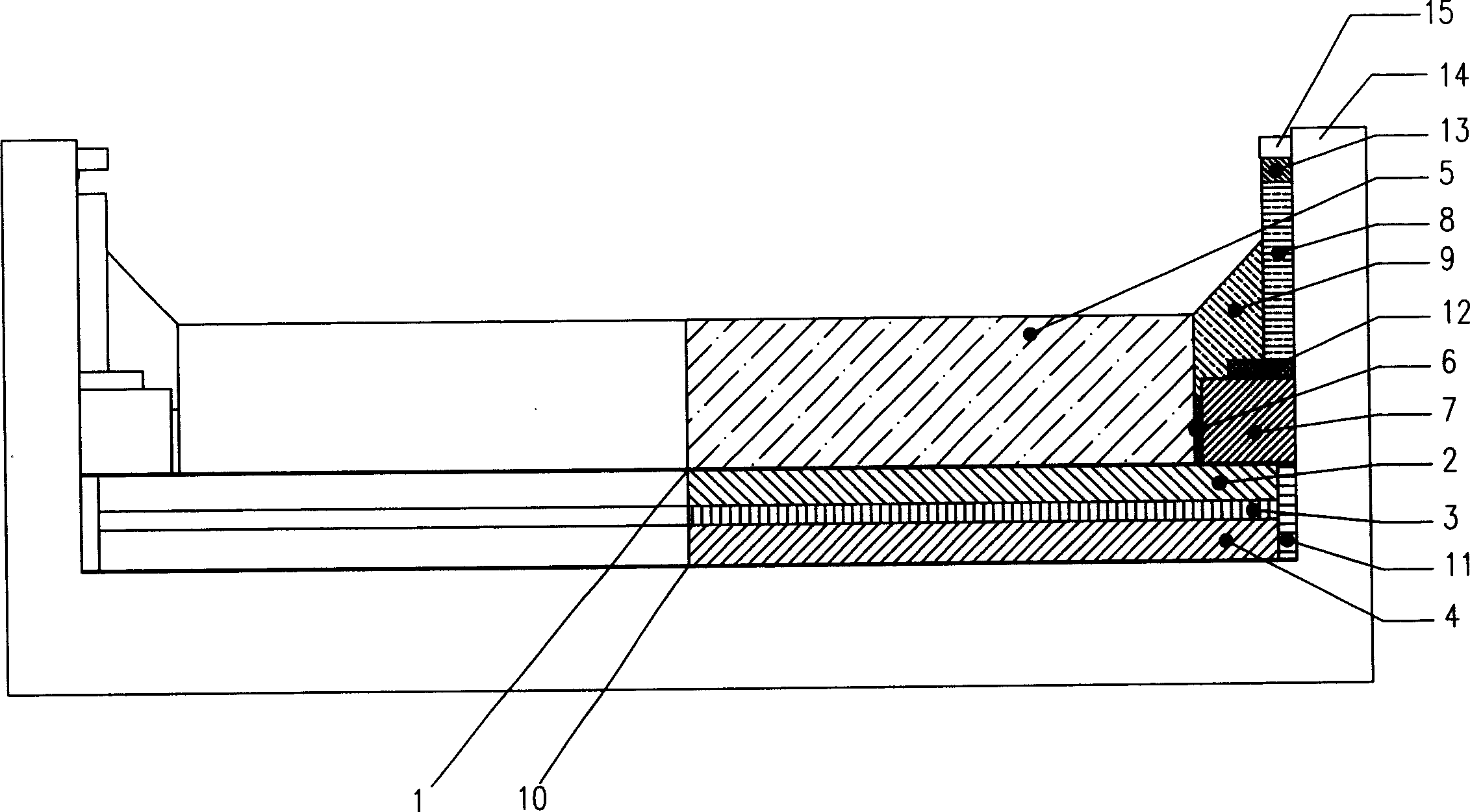

[0019] An aluminum electrolytic cell lining structure, which includes a cathode carbon block 5 and an electrolytic cell shell 14. A heat preservation zone is provided between the bottom surface of the electrolytic cell cathode carbon block 5 and the bottom upper surface of the electrolytic cell shell 14, from top to bottom , with alumina layer 1, anti-seepage brick layer 2, thermal insulation brick layer 3, refractory brick layer 4 and bottom alumina layer 10 respectively, on the sides of anti-seepage brick layer 2, thermal insulation brick layer 3 and refractory brick layer 4 The part connected to the electrolytic cell shell 14 is provided with a side buffer layer 11, and a buffer layer 6 and a side anti-seepage brick layer 7 are built between the cathode carbon block 5 and the inner wall of the electrolytic cell shell 14. Masonry silicon nitride bonded silicon carbide side block 8, the silicon nitride bonded silicon carbide side block is made of Si 3 N 4 -Sic block masonry,...

Embodiment 2

[0021] The height of the artificial leg extension described in the first embodiment is 300mm or 350mm, and the others are the same as the first embodiment.

Embodiment 3

[0023] The groove depth described in the first embodiment is 550mm or 600mm, and the others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com