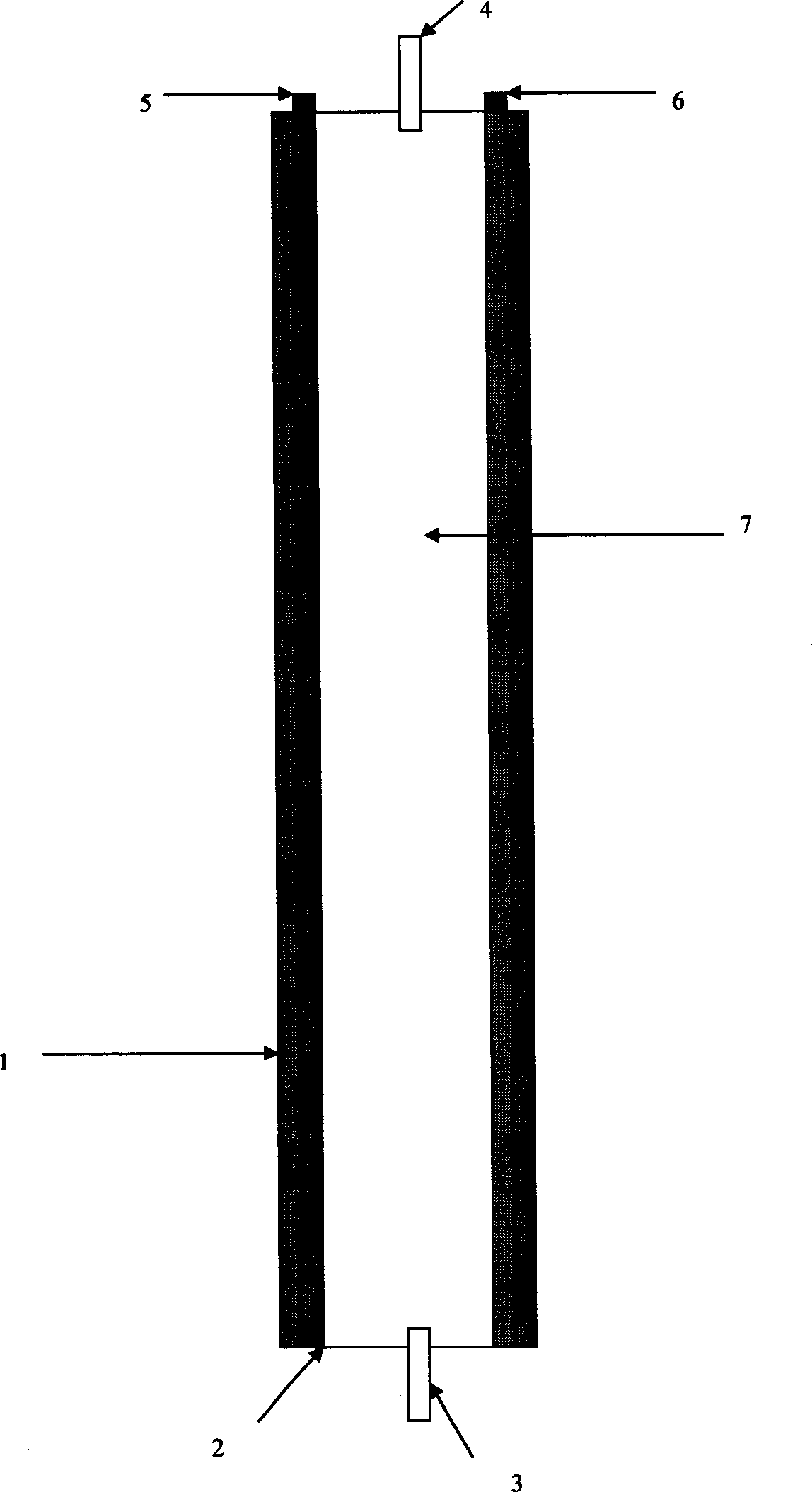

Oil smoke catalytic decomposition treating apparatus for range hoods

A catalytic decomposition and treatment device technology, which is applied in the direction of oil fume removal, separation method, and dispersed particle separation, etc., can solve the problems of heavy cleaning and maintenance workload, low particle removal rate, and high viscosity of particles in oil fume, and achieve compact structure and easy operation. Low consumption and energy saving, convenient and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The total concentration of soot exhaust gas is about 100mg / L. Exhaust air volume is 1800m 3 / h, install a set of exhaust gas purification treatment device of the present invention, the residence time of oil fume exhaust gas in the purification device is controlled within 3 seconds, and the total concentration of oil fume exhaust gas after treatment is reduced to about 2mg / L.

Embodiment 2

[0023] The total concentration of soot exhaust gas is about 220mg / L. Exhaust air volume is 1200m 3 / h, install a set of exhaust gas purification treatment device, the residence time of oil fume exhaust gas in the purification device is controlled within 3 seconds, and the total concentration of oil fume exhaust gas after treatment is reduced to about 5mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com