Electric arc pulse welder with short circuit control

一种电弧焊机、脉冲波形的技术,应用在电弧焊接领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

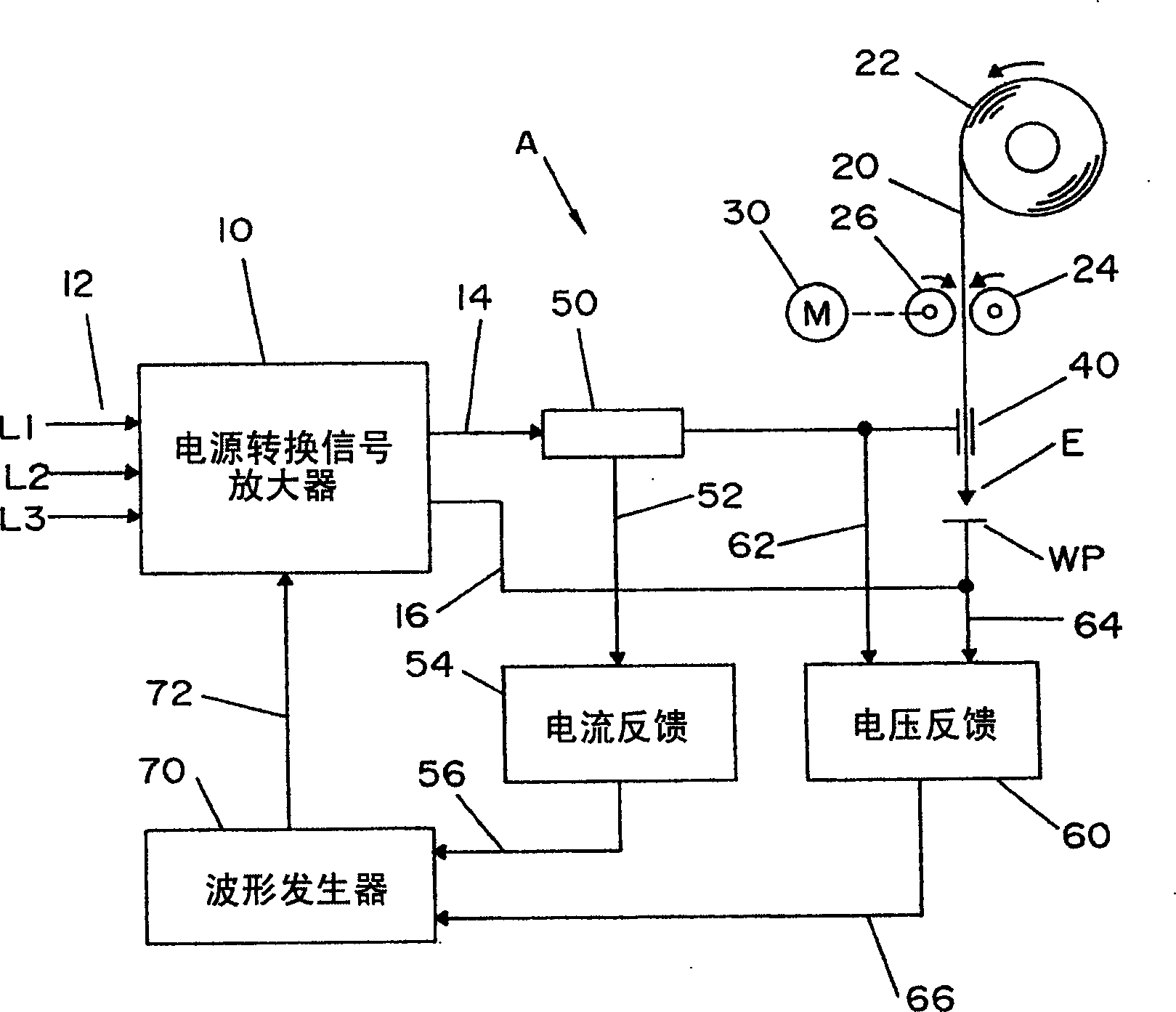

[0022]The pulsed spray welding process improved by the use of the present invention employs a standard arc welder, such as welder A shown in Figure 1, where power source 10 is a high slew rate power source, such as an inverter or circuit breaker The device has an input power supply 12, shown as a three-phase electrical input. Of course, a single phase input power source with a different voltage and frequency or even a motor or engine driven generator or alternator could be used to direct the electrical energy to the converter or power source 10 . The output leads 14, 16 are connected in series via the electrode E and the workpiece WP to perform the welding process by directing current flow between the electrode and the workpiece. In accordance with standard practice, the electrode is a continuous wire, which in the prior art is a flux-cored wire, but in the present invention is a solid-cored wire that can be used. This was not possible in some off-shore applications prior to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com