Method for making self-alignment type thin-film transistor

A technology for thin film transistors and manufacturing methods, which is applied in the manufacture of transistors, semiconductor/solid-state devices, electrical components, etc., can solve the problem of uneven chromaticity, and achieve the effect of solving uneven chromaticity and simplifying the TFT process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the description of the present invention, the term "backside exposure" or "exposure from the substrate side" refers to illuminating light toward the substrate from the side of the substrate on which no pattern or material layer is formed.

[0019] On the contrary, the term "front exposure" or "exposure from the opposite side of the substrate" in the present invention means that light is illuminated toward the substrate from the side of the substrate on which the pattern or material layer is formed.

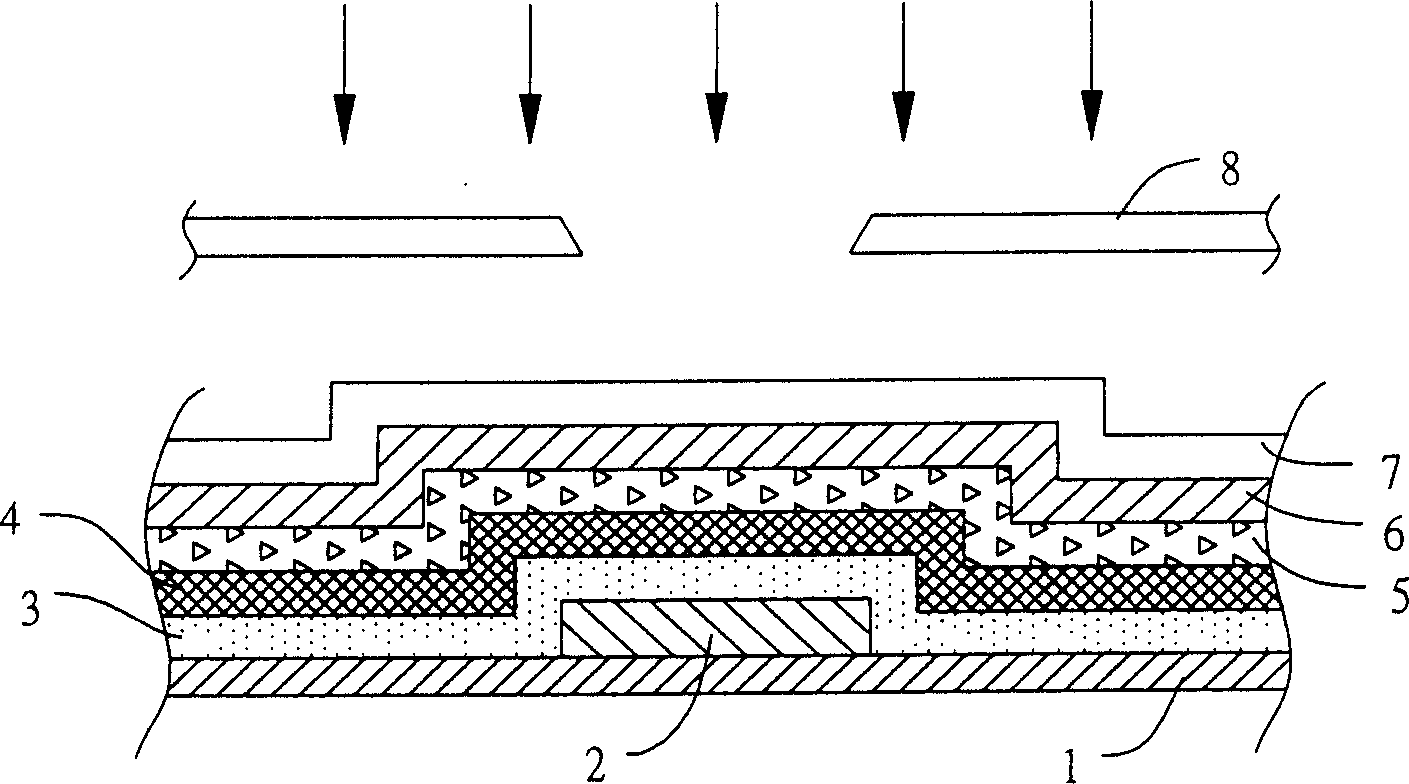

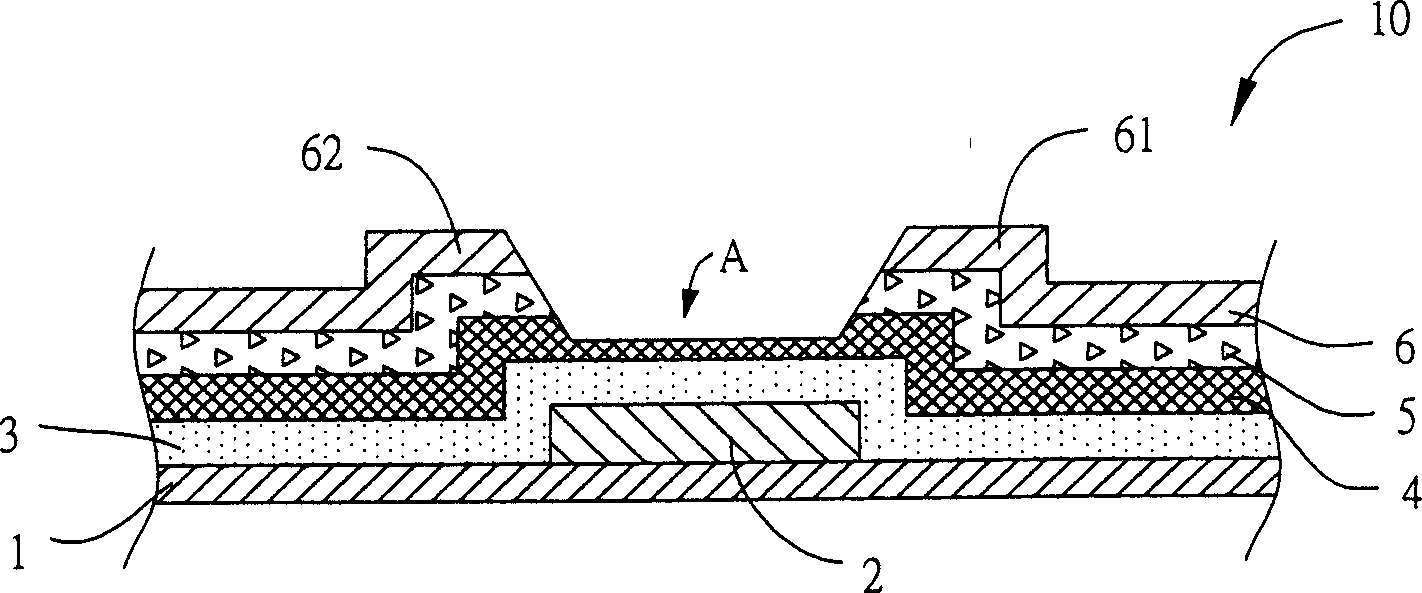

[0020] The manufacturing method of the self-aligned thin film transistor of the present invention will be described in more detail with reference to the following drawings.

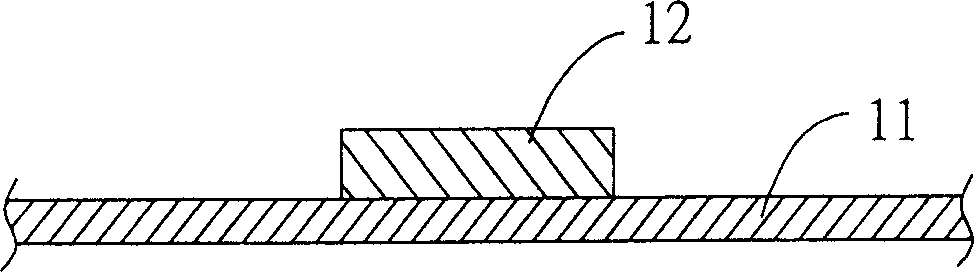

[0021] Please refer to FIG. 2 , in which a metal layer 12 with a desired pattern is formed on a substrate 11 by photolithographic etching as a gate. The substrate 11 used therein is a transparent material such as glass, quartz or plastic. The gate 12 can be any conductive metal used in the TFT fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com