Sleeve pulling shaping method of nickel titanium base marmem pipe material

A memory alloy and nickel-titanium technology, which is applied in the field of pipe processing, can solve the problems of high vacuum annealing cost, long equipment occupation time and high production cost, and achieve the effect of less drawing passes, less equipment occupation and low production cost.

Inactive Publication Date: 2005-10-26

JIANGSU FASTEN TECH DEV CENT

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because each deformation of cold rolling is very small, there are many cold rolling passes; the cost of vacuum annealing is high and the time is long

Therefore, this process is labor-intensive and time-consuming, takes up equipment for a long time, and has high production costs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0021] 1. Test conditions:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

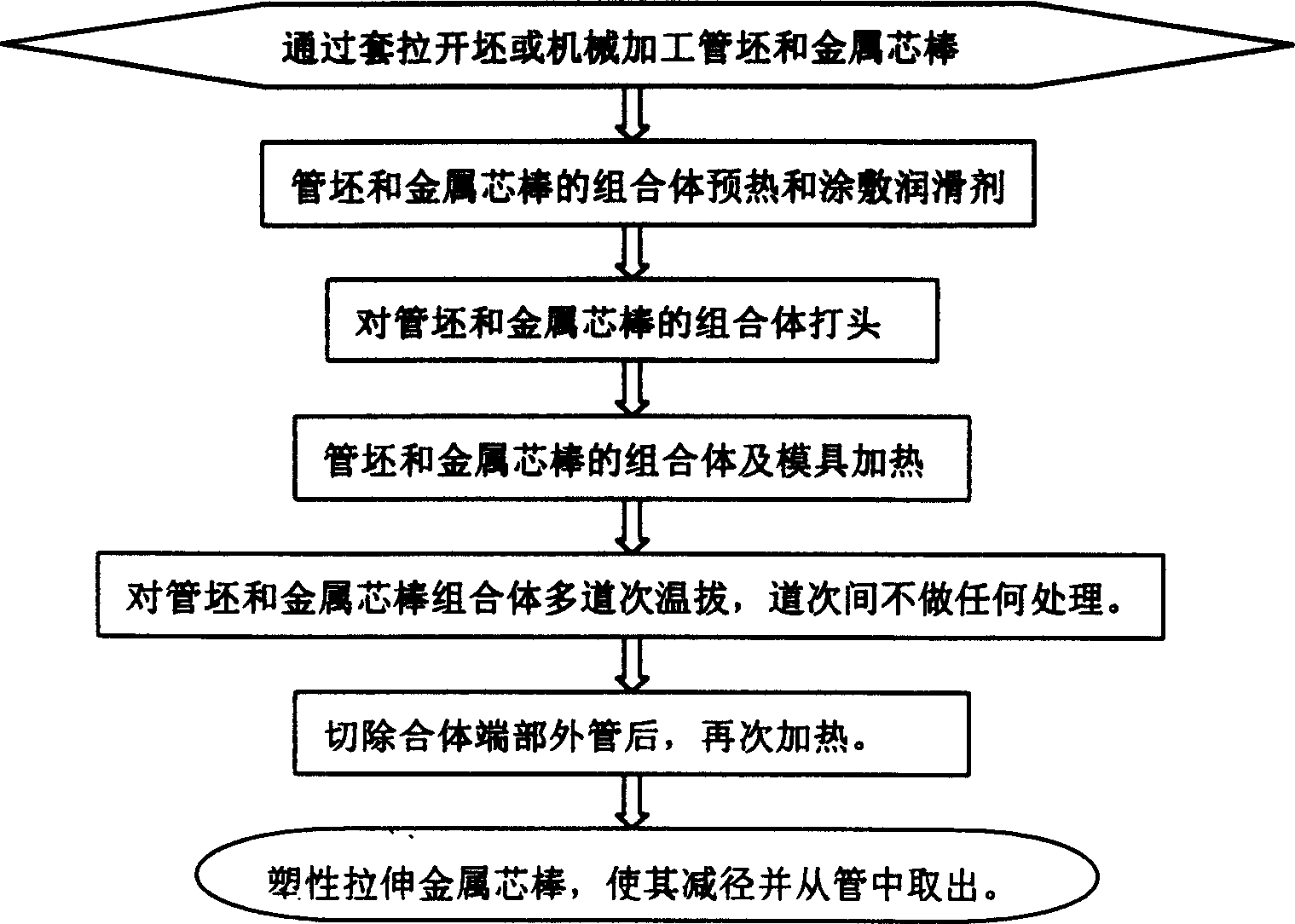

A sleeving-pulling technology for manufacturing the NiTi-based marmem pipe includes machining NiTi-based marmem pipe blank and mandrel, heating them and die to 200+ / -10 deg.C, spraying lubricant,inserting the mandrel in the pipe blank, reducing the diameter of both ends, heating it to 700+ / -20 deg.C and die to 350+ / -10 deg.C, drawing more times while spraying lubricant, cutting out both ends, heating to 800-850 deg.C, and pulling the mandrel out of the pipe.

Description

Technical field: [0001] The invention relates to a pipe forming method, in particular to a nickel-titanium-based shape memory alloy pipe sleeve-drawing forming method. It belongs to the technical field of pipe processing. Background technique: [0002] Nickel-titanium-based shape memory alloy pipes are widely used in fasteners, connectors and medical fields. Nickel-titanium-based shape memory alloy seamless pipe is a difficult-to-machine profile. For decades, the plastic forming of nickel-titanium-based shape memory alloy pipes has been one of the difficulties and hot spots in the field of plastic processing engineering at home and abroad. Its products have important applications in hydraulic pipe joints, various types of catheters in the medical field, various types of vascular stents, miniature reconnaissance aircraft, insect robots and other miniature weapons and equipment, as connecting parts and carrying connections. Before the present invention was made, the domesti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21C1/24

Inventor 陈威刘礼华张伟红谭佃龙李运良张士宏孙文蔡伟王利明

Owner JIANGSU FASTEN TECH DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com