Method for removing tellurium from coarse selenium

A technology of coarse selenium and selenium powder, applied in the direction of elemental selenium/tellurium, etc., can solve the problems of polluted environment, low recovery rate of selenium, serious problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

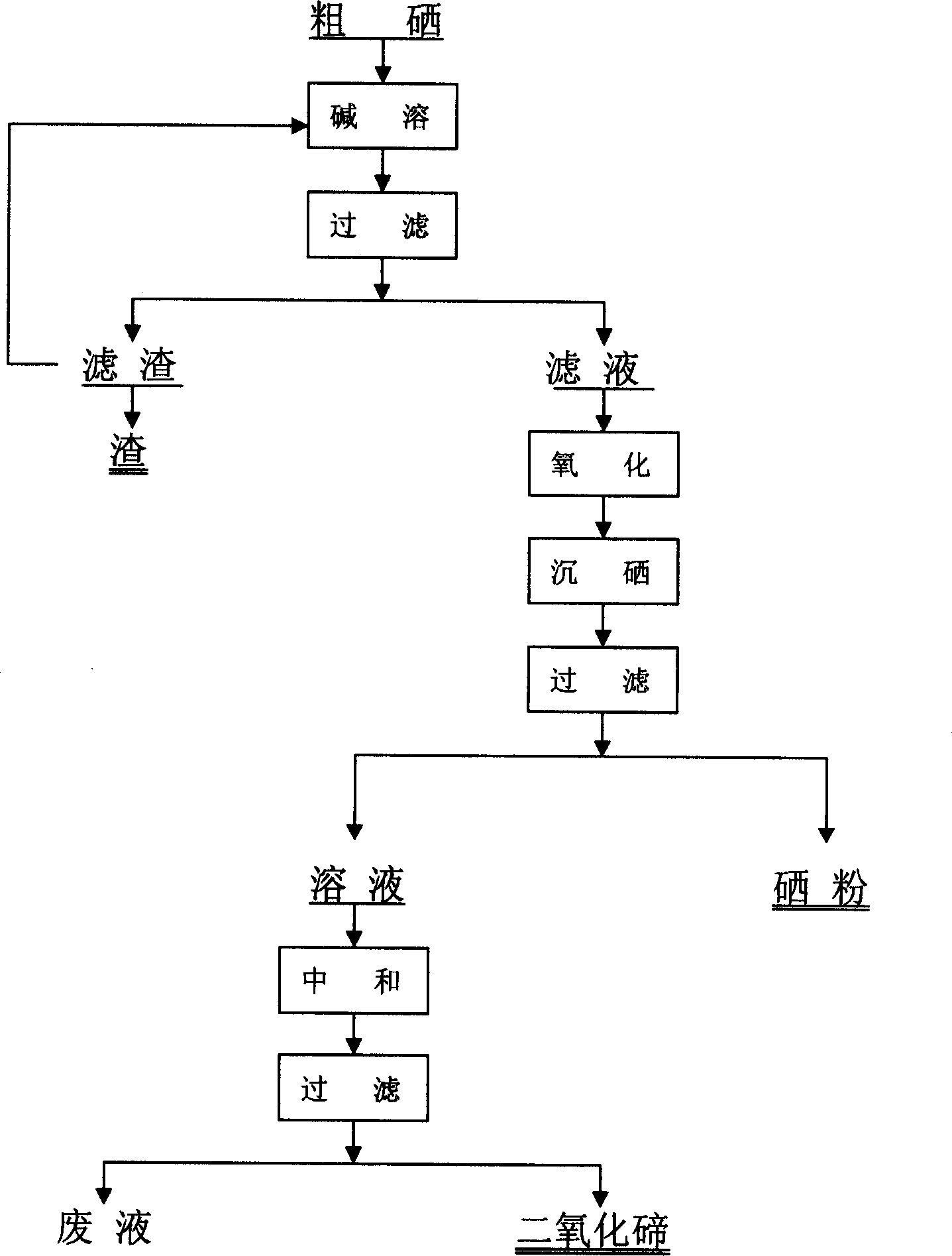

Method used

Image

Examples

Embodiment 1

[0007] 100g of crude selenium containing 90% of selenium and 7.5% of tellurium was added with a concentration of 40% sodium hydroxide solution, the solid-to-liquid ratio was 1:2.5, the reaction temperature was 90°C, the reaction time was 4 hours, the volume was diluted 0.75 times, and filtered. The filtrate was added to the oxidation equipment and oxidized with oxygen. The oxidation time was 30 hours. The pH of the solution was adjusted to 12 with dilute sulfuric acid to obtain selenium powder precipitation. After filtering, washing and drying, 87.27g of selenium powder was obtained. The pH of the filtrate was adjusted to 5 with dilute sulfuric acid to obtain tellurium dioxide precipitate. The recoveries of selenium and tellurium are 96% and 95.5% respectively, and the selenium powder contains 99% selenium and 0.35% tellurium.

Embodiment 2

[0009] Same as Example 1. 100g crude selenium contains 82.5% selenium, 12.6% tellurium, the concentration of sodium hydroxide solution is 30%, the solid-to-liquid ratio is 1: 1.5, the reaction temperature is 85°C, the reaction time is 5 hours, the volume is diluted by 1 time, and filtered , the filtrate was oxidized by air for 35 hours, and the pH of the solution was adjusted to 13 with dilute sulfuric acid to obtain selenium powder precipitation, and the pH of the filtrate was adjusted to 4.5 to obtain tellurium dioxide precipitation. The selenium powder weighs 81.4g after washing and drying, and the selenium powder contains 96.4% of selenium and 0.43% of tellurium. The recoveries of selenium and tellurium were 95.1% and 95.8%, respectively.

Embodiment 3

[0011] Same as Example 1. 100g thick selenium contains 80.2% selenium, 17.5% tellurium, the concentration of sodium hydroxide solution is 35%, the solid-to-liquid ratio is 1:2, the reaction temperature is 75°C, the reaction time is 6 hours, the volume is diluted by 0.5 times, and filtered , the filtrate was oxidized by oxygen for 25 hours, the pH of the solution was adjusted to 13 with dilute sulfuric acid to obtain selenium powder precipitation, and the pH of the filtrate was adjusted to 5 to obtain tellurium dioxide precipitation. The selenium powder weighs 80.54g after being washed and dried, and contains 95.6% of selenium and 0.5% of tellurium. The recoveries of selenium and tellurium were 96% and 96.2%, respectively.

[0012] The recovery rates of selenium and tellurium in the method of the invention are higher than those of the oxygen combustion-reduction method. The environment pollution and equipment corrosion caused by the escape of selenium dioxide and the release o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com