Preparation method of methane chloride

A technology of monochloromethane and methanol, which is applied in the field of preparation of monochloromethane, can solve environmental problems and other problems, and achieve the effects of no environmental pollution, saving investment, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

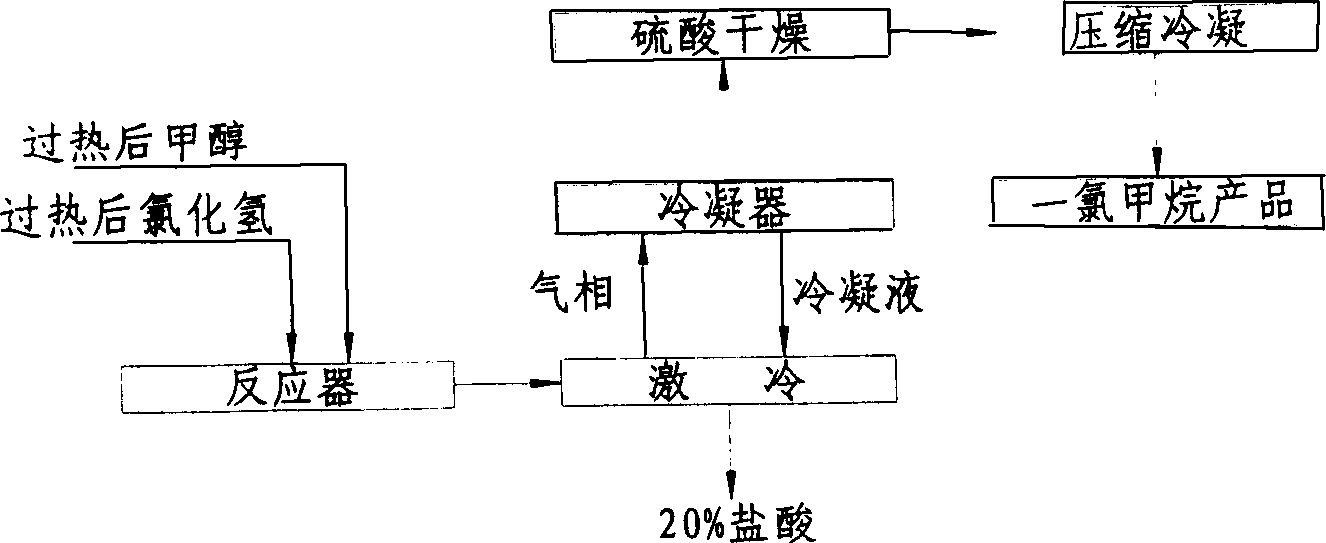

[0012] The methanol and hydrogen chloride superheated to 180-220℃ are 1:1.1-1.3 (molar ratio), in the presence of a proprietary catalyst, under the conditions of 280-320℃, 0.2-0.4MpaG, the gas phase reacts to produce monochloromethane and water After the high temperature reaction gas exiting the reactor is chilled by dilute hydrochloric acid, the temperature is reduced to about 90-140℃. The separated chilled liquid is 20% hydrochloric acid (the acid is used to produce 31% hydrochloric acid for external sales), and the separated moisture Condensed by a condenser (dilute hydrochloric acid is used for the quenching of the reaction gas in the condensate), dried with sulfuric acid, and compressed and condensed to obtain monochloromethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com