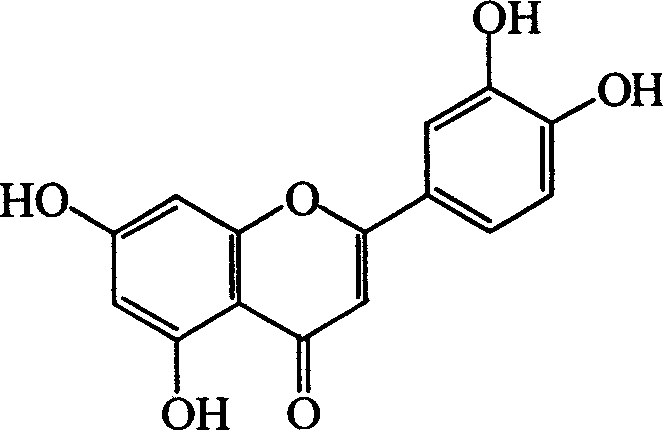

Method for preparing compound of luteolin

A technology for luteolin and compound, applied in the field of preparation of luteolin compound, can solve problems such as low yield, achieve the effects of high product purity and yield, simple and easy operation and control, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Purification of raw materials: add 30 grams of rutin to 1000 mL of water, slowly add 30% NaOH solution under stirring at a constant temperature of 80°C until the rutin is completely dissolved, filter and cool to room temperature, and adjust the pH of the filtrate to 3.2 with hydrochloric acid , yellow crystals were precipitated, filtered, washed with water, and vacuum-dried at 95°C to obtain 24.4 g of refined rutin.

[0025] 2. Preparation of luteolin: add 20 grams of NaOH to 600 mL of deionized water, after dissolving, add 18 grams of refined rutin, stir to obtain a dark red solution. Add 90g Na 2 S 2 o 4 , 300W microwave heating and reflux for 1 hour (20min.×3), cooled to room temperature, the reaction solution was neutralized with hydrochloric acid to pH=4.0, left to stand, filtered, washed with water, and vacuum-dried at 85°C to obtain 97.8% luteolin 5.3 g, yield 61.3%.

[0026] 3. Purification of luteolin products: add 5.3 grams of luteolin to 300 ml of 60% ...

Embodiment 2

[0028] 1. Purification of raw materials: Heat 2000mL of water to 70°C, add 60g of isoquercetin, slowly add 30% NaOH solution at 70°C with stirring until the isoquercetin is completely dissolved, filter and cool to room temperature, Adjust the pH to 3.2 with hydrochloric acid, precipitate yellow crystals, filter, wash with deionized water, and vacuum-dry at 95°C to obtain 50.5 g of refined isoquercetin.

[0029] 2. Preparation of luteolin: add 70 grams of sodium carbonate to 2000 mL of deionized water, after it dissolves, add 50 grams of isoquercetin refined product and 320 grams of Na 2 S 2 o 4 , 250W microwave heating and reflux for 1.5 hours (15min.×6), stop heating, cool to room temperature, neutralize with hydrochloric acid to pH = 2.2, stand overnight at room temperature, filter, wash with water, and vacuum dry at 95°C to obtain 92.2% 23.7 grams of luteolin, yield 72.9%.

[0030] 3. Purification of luteolin products: add 23.7 grams of crude luteolin to 1200 ml of 95% e...

Embodiment 3

[0032] 1. Purification of raw materials: heat 1000mL of water to 90°C, add 40g of rutin, slowly add 30% NaOH solution at 90°C with stirring until the rutin is completely dissolved, filter and cool to room temperature, adjust the pH with hydrochloric acid =3.2, yellow crystals were precipitated, washed with deionized water, and vacuum-dried at 100° C. to obtain 31.8 grams of refined rutin.

[0033] 2. Preparation of luteolin: add 18 grams of KOH to 500 mL of deionized water, after it dissolves, add 12 grams of refined rutin and 96 grams of Na 2 S 2 o 4 , 300W microwave heating to reflux for 1 hour (20min.×3), stop heating, cool the reaction solution to room temperature, neutralize with hydrochloric acid to pH=5.6, cool to below 5°C, filter, wash with deionized water, and vacuum dry at 75°C , 4.1 grams of 94.2% luteolin can be obtained, and the yield is 71.2%.

[0034] 3. Purification of luteolin products: Add 4.1 grams of crude luteolin to 200 ml of methanol, heat to dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com