Vertical orientated liquid crystal orientation agent and liquid crystal display member

A technology of liquid crystal display elements and liquid crystal alignment agents, applied in sliding fastener elements, fasteners, applications, etc., can solve the problems of uneven thickness of alignment film, mottled brightness, pinholes, etc., and achieve good vertical alignment and voltage retention The effect of high rate and good spreadability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0060] As specific examples of diamines having groups represented by the above formula (Q-1), preferred examples include dodecyloxy-2,4-diaminobenzene, pentadecyloxy-2,4- Diaminobenzene, hexadecyloxy-2,4-diaminobenzene, octadecyloxy-2,4-diaminobenzene, compounds represented by the following formulas (13) to (29).

[0061] [chemical 11]

[0062]

[0063] [chemical 12]

[0064]

[0065] In addition, as R in the above formula (Q-2) 2 The divalent organic group having an alicyclic skeleton and having 4 to 40 carbon atoms, for example, includes alicyclic skeleton derived from cycloalkane such as cyclobutane, cyclopentane, cyclohexane, and cyclodecane. divalent organic groups; divalent organic groups with steroid skeletons such as cholesterol and cholestanol; divalent organic groups with bridging alicyclic skeletons such as norbornene and adamantane, etc. Among them, a divalent organic group having a steroid skeleton is particularly preferable. The aforementioned divalent ...

Embodiment

[0114] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited to these examples.

[0115] [Measuring method of imidization rate of imidized polymer]

[0116] After the imidized polymer is dried under reduced pressure at room temperature, it is dissolved in deuterated dimethyl sulfoxide, and measured at room temperature with tetramethylsilane as a standard substance 1H-NMR is obtained by the formula shown in the following formula (ii): have to.

[0117] Imidization rate (%) = (1-A 1 / A 2 ×α)×100 ------(ii)

[0118] A 1 : Proton original peak area of NH group (10ppm)

[0119] A 2 : Original peak area of other protons

[0120] α: The ratio of the number of other protons to the protons of the NH group in one polymer precursor (polyamic acid)

[0121] [Manufacturing method of liquid crystal display element]

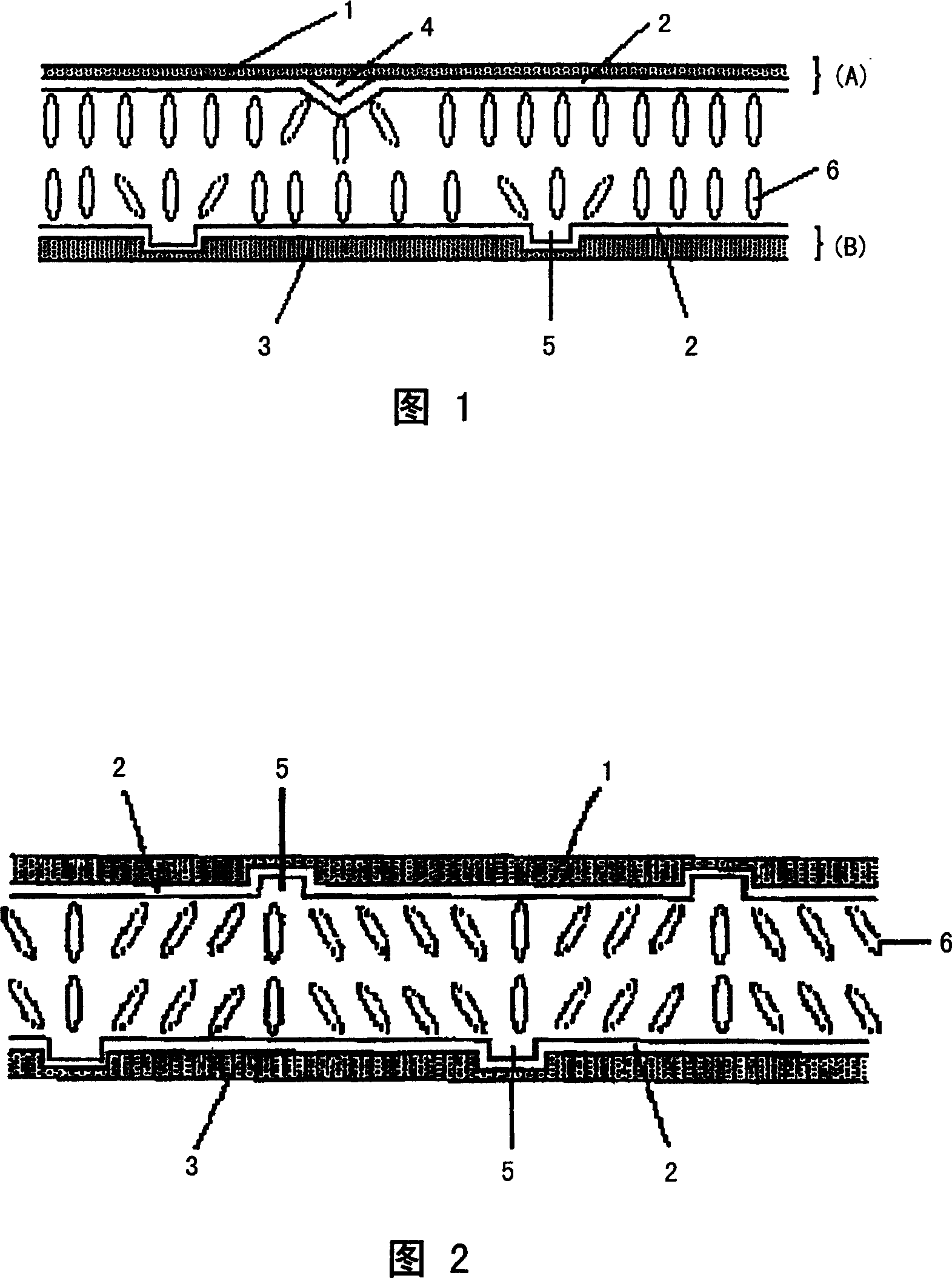

[0122] On the glass substrate (A) and the glass substrate (B) with the ITO pattern of...

Synthetic example 1~14

[0133]With the composition shown in Table 1, diamine and tetracarboxylic dianhydride were sequentially added to N-methyl-2-pyrrolidone so that the concentration of solid content was 20%, and reacted for 4 hours while stirring at room temperature. Then, the solution was poured into a large excess of pure water to precipitate the reaction product, and then, the solid matter was separated and washed with pure water, and dried at 40° C. for 15 hours under reduced pressure to obtain a white powdery polyamic acid. The polyamic acid obtained in this way was dissolved in N-methyl-2-pyrrolidone so that the solid content concentration was 7%, and after adding pyridine and acetic anhydride in the ratios shown in Table 1 to 1 mole of repeating units, respectively, it was heated at 110° C. Heating for 4 hours for dehydration ring closure reaction. The resulting reaction solution was poured into a large excess of pure water to precipitate the reaction product. Then, the solid was separated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com