External wall tile wall on heat insulating layer of combined placing concrete and polyphenyl board and construction method

A construction method and technology of polystyrene board, applied in the direction of walls, structural elements, building components, etc., can solve the problems of low bonding strength, poor fire resistance, and easy falling off of external veneer adhesive tiles, so as to improve the bonding strength, The effect of enhancing fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment one sees Figure 1-7 , Concrete combined pouring polystyrene board external insulation paste face brick wall construction method steps:

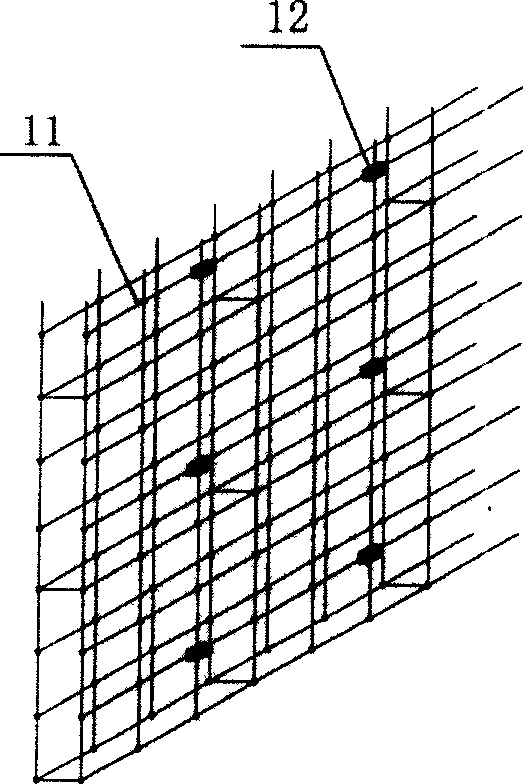

[0043] a. Bind the wall reinforcement cage 11 on the wall foundation, and on the reinforcement outside the wall, according to the thickness requirement of the concrete protective layer, fix pads 12 at intervals.

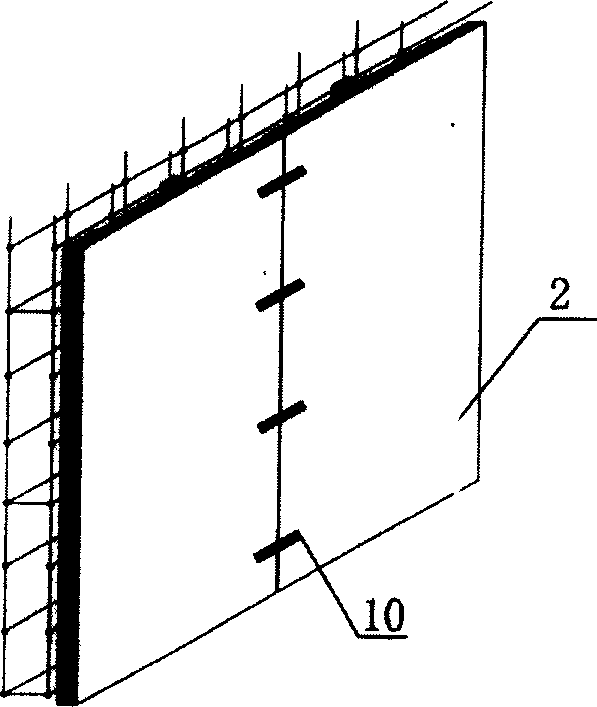

[0044] b. Place a layer of non-mesh polystyrene board 2 on the outer side of the reinforcement cage. The two sides of the polystyrene board are pre-painted with an interface mortar layer, and the joints of the polystyrene board are coated with adhesive glue and fixed with adhesive tape; Two polystyrene boards can be connected together with plastic staples 10 on both sides of the slab seam of the benzene board, and the plastic staples are bound and fixed on the steel bars.

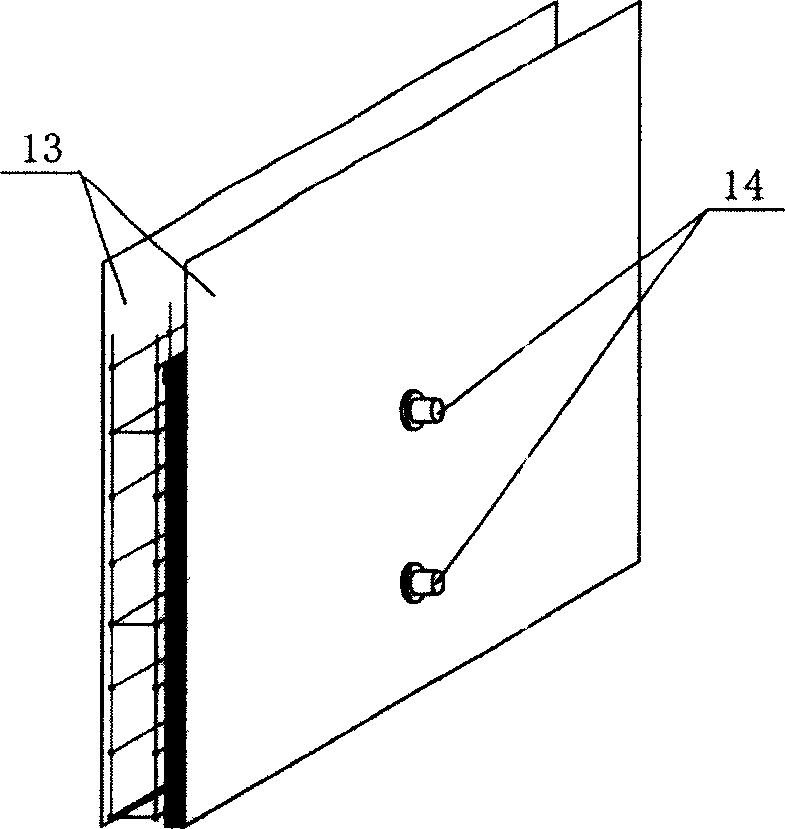

[0045] c. Fix the inner and outer formwork 13 in the wall on the outer side of the reinforcement cage and the polystyrene board, and cross th...

Embodiment 2

[0052] Embodiment two see Figure 8-14 , the construction method steps of concrete combined pouring polystyrene board external thermal insulation pasting brick wall:

[0053] a. Bind the outer wall reinforcement cage 11 on the wall foundation, and fix pads 12 at intervals on the outer reinforcement according to the thickness requirements of the concrete cover.

[0054] b. Place a layer of netted polystyrene board 9 on the outer side of the reinforcement cage. The two sides of the polystyrene board are sprayed with an interface mortar layer. The joints of the polystyrene board are coated with adhesive glue, and the tape is pasted on the outside to seal the board seam. seal up.

[0055] c. Fix the inner and outer formwork 13 in the wall on the two outer sides of the steel cage and the polystyrene board, and cross the wall bolt 14 in the middle of the formwork.

[0056] d. After the formwork is erected, fasten a trough cover 15 on the upper end of the polystyrene board, pour co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com