Sintering rear-earth permanent-magnetic alloy and its manufacturing method

A technology of permanent magnets and alloy ingots, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of reducing the coercive force of the magnets, the magnets cannot be used, and achieves the reduction of remanence and magnetic energy product, Ease of control and improved coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, a double alloy method is used to manufacture the magnet. The composition of the main alloy is R 14.5 (Fe,TM) 79.5 B 6 (R=Nd, Pr, Dy, Tb; TM=Co, Cu, Al, Nb, etc.) ingot, the secondary alloy is obtained by arc melting, and its composition is R 14.5 (Fe, TM, Cr) 79.5 B 6 (R=Nd, Pr, Dy, Tb; TM=Co, Cu, Al, Nb, etc.). Put them into two stainless steel tanks respectively for hydrogen crushing (HD). After hydrogen crushing, mix the powder according to a certain ratio, then carry out jet milling, orient and shape it under a magnetic field of 2T, and add 200MPa isostatic pressure. The sintering was carried out in a vacuum state at ℃, and the obtained magnet was annealed at 620℃ for 5 hours. Table 1 lists the magnetic properties of magnets with different Cr contents.

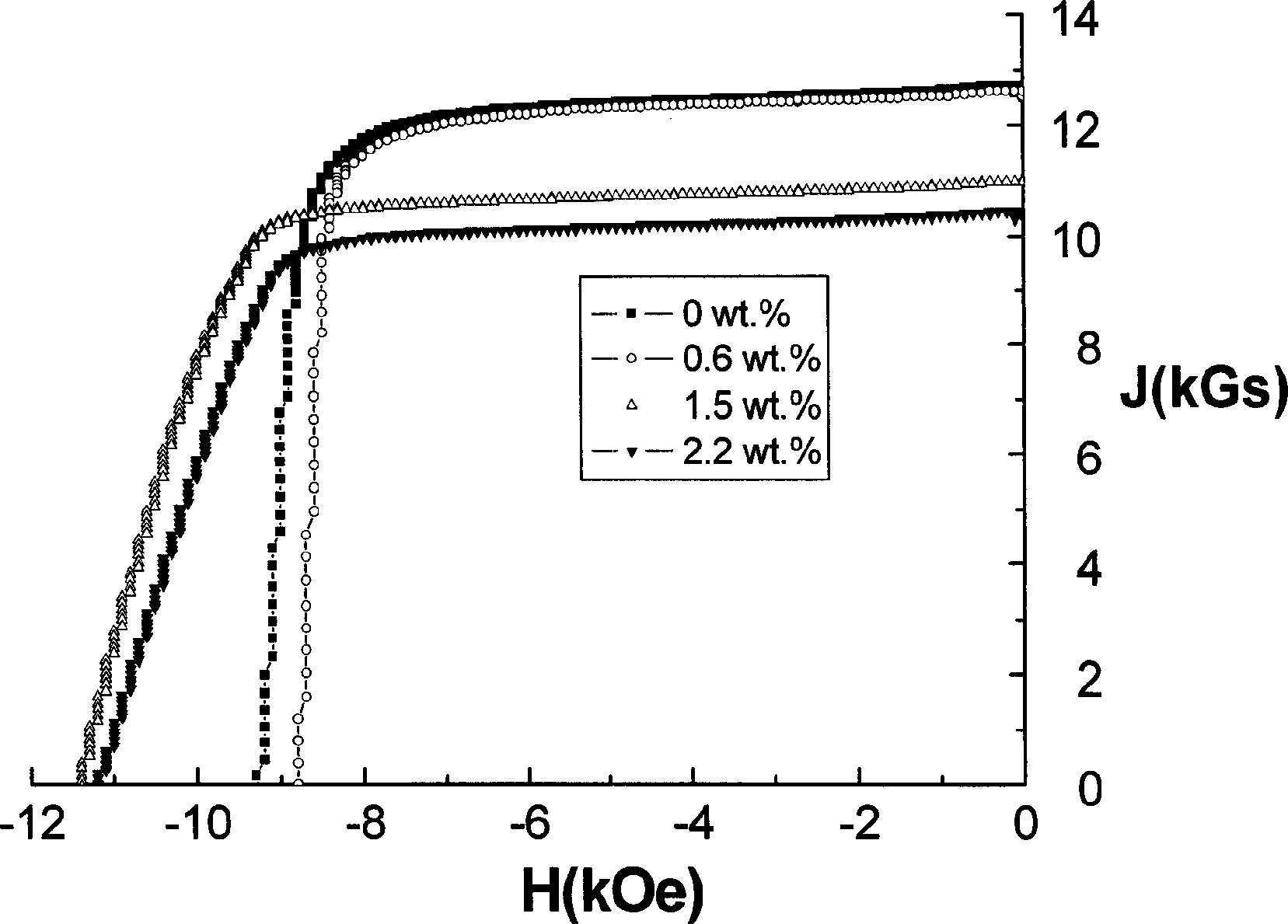

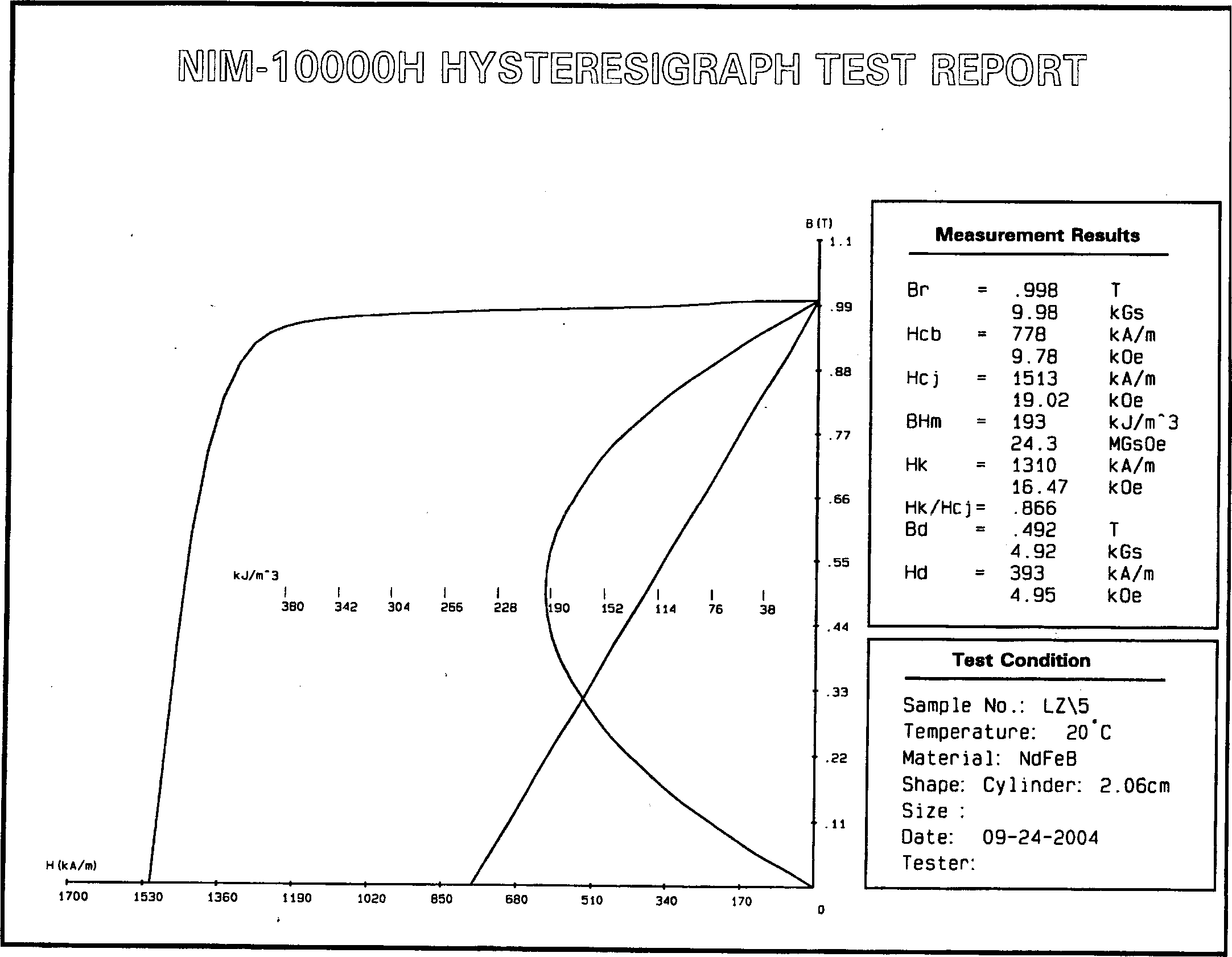

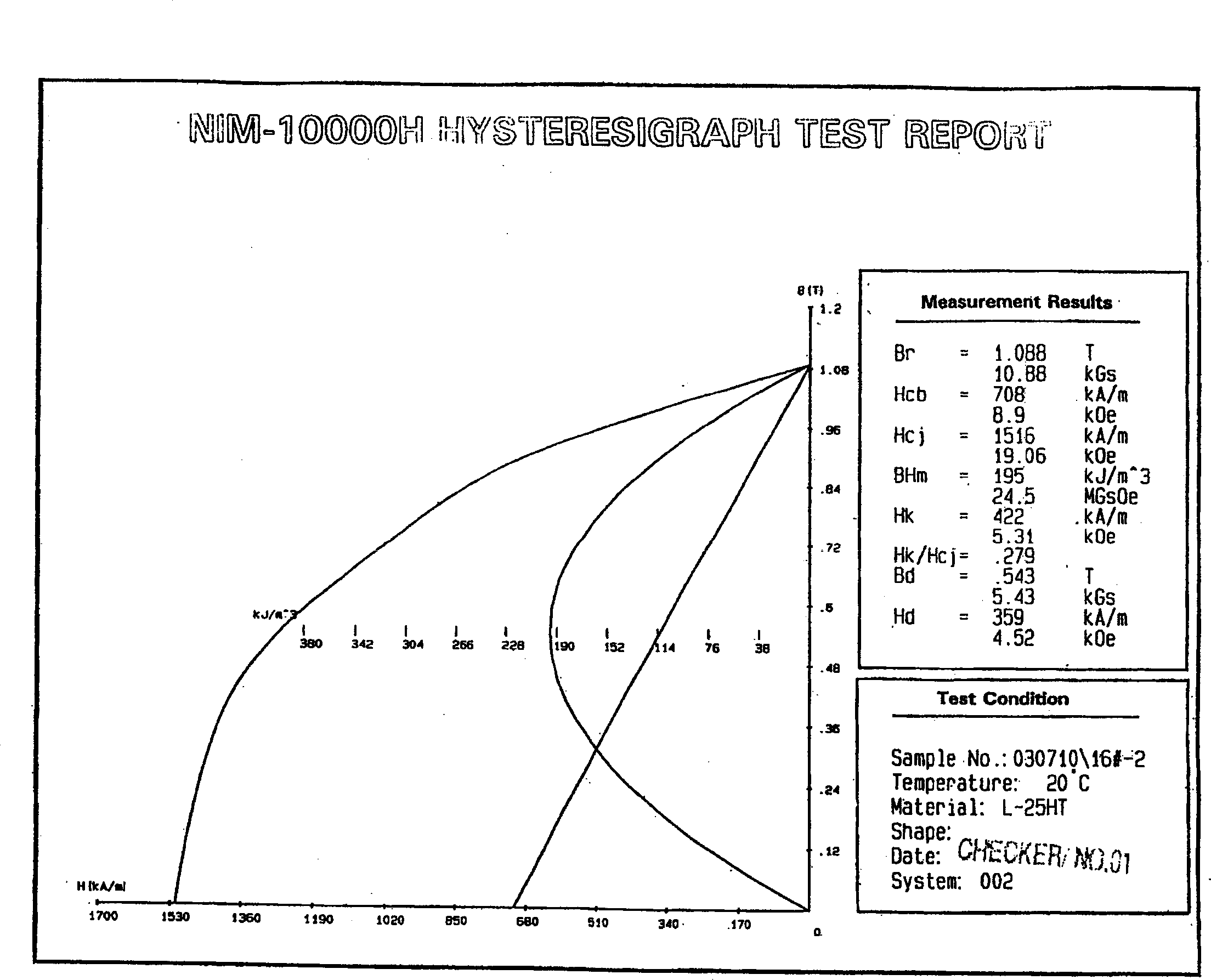

[0040] The demagnetization curves of the sintered and annealed magnets were measured using a MagnetPhysik permanent magnet measurement system and a NIM-10000H permanent magnet material mea...

Embodiment 2

[0047] Using the double alloy method, the main alloy is the composition R 14.5 (Fe,TM) 79.5 B 6 (R=Nd, Pr, Dy, Tb; TM=Co, Cu, Al, Nb, etc.) ingot, the secondary alloy is obtained by arc melting, and its composition is R 14.5 (Fe, TM, Mn) 79.5 B 6 (R=Nd, Pr, Dy, Tb; TM=Co, Cu, Al, Nb, etc.). Put them into two stainless steel tanks for hydrogen crushing (HD). After hydrogen crushing, mix the powder according to a certain ratio, then perform jet milling, orient and shape it under a magnetic field of 2T, add 200MPa isostatic pressure, and finally in a vacuum state Carry out sintering. Get the coercive force H cj Magnets greater than or equal to 4kOe, remanence less than 1.1T, and energy product less than 30MGOe.

Embodiment 3

[0049] Using a single alloy method, the composition is R 14.5 (Fe, TM, AF) 79.5 B 6 Ingots of (R=Nd, Pr, Dy, Tb; TM=Co, Cu, Al, Nb; AF=Cr, Mn, etc.). Put it into a stainless steel tank for hydrogen crushing (HD), then jet mill, orient and shape under a magnetic field of 2T, apply 200MPa isostatic pressure, and finally sinter in a vacuum state. A magnet having magnetic properties comparable to Example 1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com