Method for preparing particle reinforced Fe-C composite material with big section and high volume fraction

A high volume fraction, composite material technology, applied in the field of preparation of Fe-C composite materials with large cross-section and high volume fraction reinforced by external particles, can solve the problems of complex manufacturing process, complex preparation process, expensive equipment, etc., and achieve high material utilization rate , Simple production process and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

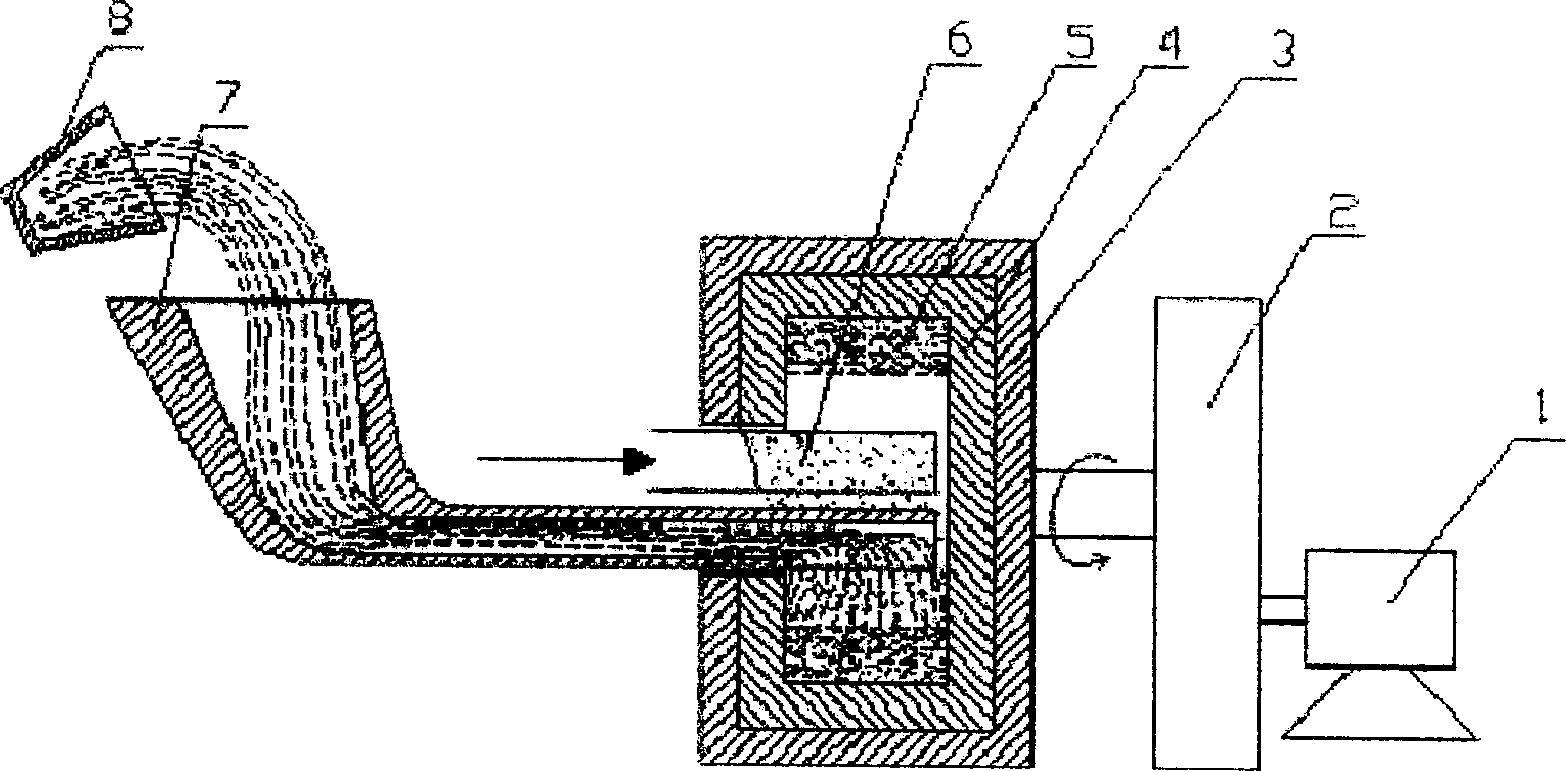

Method used

Image

Examples

Embodiment 2

[0023] Its preparation method is the same as that of Example 1, and the reinforcement particles adopt titanium carbide (TiC) particles. After the TiC particles are uniformly mixed with the Fe-C alloy liquid, an annular mixture 5 is formed in the centrifugal field. The TiC particles are due to its density (4.93g / cm 3 ) is less than the Fe-C alloy liquid density (7.1g / cm 3 ) and migrate toward the inner layer along the radial direction of the ring, forming a composite structure annular part of the inner layer of the TiCp / Fe-C composite material and the outer layer of the Fe-C alloy matrix.

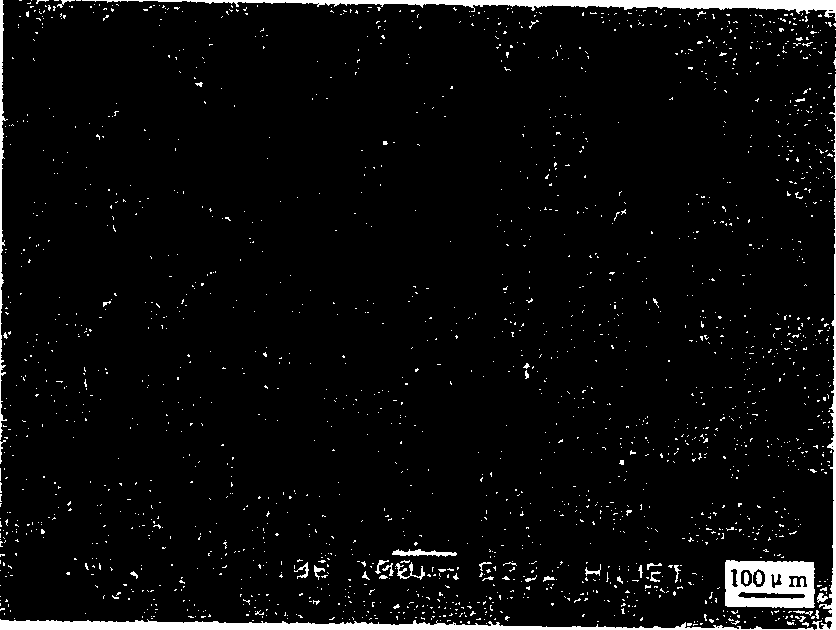

[0024] Such as figure 2 As shown, the radial slice analysis of the prepared composite structure annular parts shows that the thickness of the WCp / Fe-C composite layer is greater than 20mm, and the thickness of the composite layer can be controlled by controlling the amount of reinforcing particles added, and the volume fraction of WCp in the composite layer is greater than 70%. , WCp volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com