Large-scale apparatus for synthesis of trichlorosilane and synthesis method thereof

A synthesis device, trichlorosilane technology, applied in the direction of silicon halide compounds, halosilane, etc., can solve the problems of low raw material utilization rate or conversion rate, low trichlorosilane content, small synthesis capacity, etc., to increase gas Fixed contact time, high product quality, stable reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

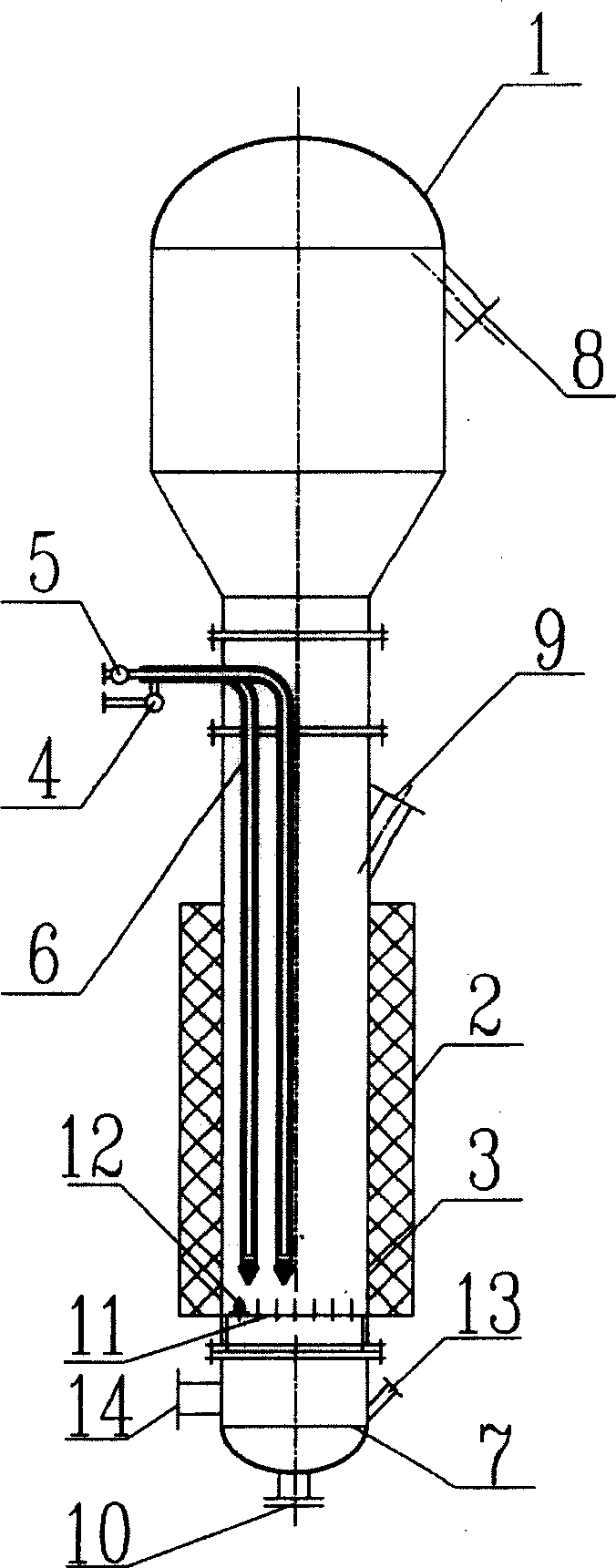

[0029] Examples see figure 1 , the large-scale trichlorosilane synthesis device of the present invention has a cylindrical structure, and the enlarged part of the upper cylinder body is a gas-solid separation section 1, and the neck of the gas-solid separation section 1 is rounded and truncated, and this section is provided with a discharge port 8, The opening of discharge port 8 is inclined downward, which is beneficial to discharging.

[0030] The straight barrel section in the middle is the reaction section 2, the reaction section is covered with a heater 3, and a silicon powder feed port 9 is arranged above the heater, and the opening of the silicon powder feed port 9 is inclined upward, which is beneficial for feeding.

[0031] The bottom is connected to the lower head 7, and the lower head is provided with a hydrogen chloride inlet 10 and a slag discharge port 13, and a pressure measuring port 14 can also be provided when necessary.

[0032] A gas distribution plate 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com