Raw material preheating system for calcium carbide production procedures and method for applying raw material preheating system

A production process and raw material technology, applied in the petroleum industry, special dry distillation, carbide, etc., can solve the problems of serious energy loss, high pollution, high investment, etc., and achieve the effect of reducing carbon loss, reducing investment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

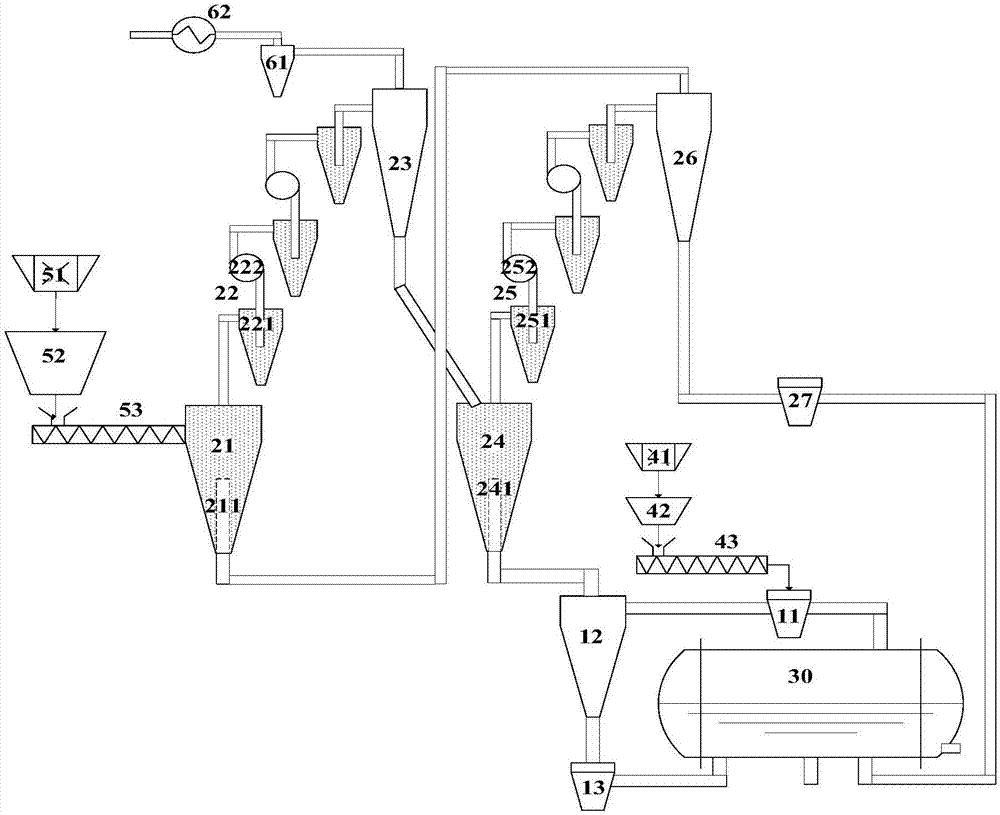

[0106] This example uses figure 1 The system shown performs calcium carbide production, and specific methods include:

[0107] (E) In the oxythermite reactor, semi-coke and carbon-coated calcium oxide particles react to form calcium carbide liquid and high-temperature gas, and the high-temperature gas is sent to the pulverized coal-heat medium mixer through the high-temperature tail gas outlet.

[0108] (J) Coal is pulverized and dried by a coal pulverizer to obtain pulverized coal, which is stored in a pulverized coal storage tank and sent to a pulverized coal-heat medium mixer through a pulverized coal screw conveyor. The pulverized coal sent to the pulverized coal-heat medium mixer is 5000Kg / h.

[0109] (A) In the pulverized coal-heat medium mixer, mix the pulverized coal obtained in step (J) with the high-temperature gas obtained in step (E) to heat and pyrolyze the pulverized coal, and send the pyrolysis product into the semi-coke separator. The pyrolysis temperature is 1...

Embodiment 2

[0121] This example uses figure 1 The system shown performs calcium carbide production, and specific methods include:

[0122] (E) In the oxythermite reactor, semi-coke and carbon-coated calcium oxide particles react to form calcium carbide liquid and high-temperature gas, and the high-temperature gas is sent to the pulverized coal-heat medium mixer through the high-temperature tail gas outlet.

[0123] (J) Coal is pulverized and dried by a coal pulverizer to obtain pulverized coal, which is stored in a pulverized coal storage tank and sent to a pulverized coal-heat medium mixer through a pulverized coal screw conveyor. The pulverized coal sent into the pulverized coal-heat medium mixer is 4000Kg / h.

[0124] (A) In the pulverized coal-heat medium mixer, mix the pulverized coal obtained in step (J) with the high-temperature gas obtained in step (E) to heat and pyrolyze the pulverized coal, and send the pyrolysis product into the semi-coke separator. The pyrolysis temperature ...

Embodiment 3

[0136] This example uses figure 1 The system shown performs calcium carbide production, and specific methods include:

[0137] (E) In the oxythermite reactor, semi-coke and carbon-coated calcium oxide particles react to form calcium carbide liquid and high-temperature gas, and the high-temperature gas is sent to the pulverized coal-heat medium mixer through the high-temperature tail gas outlet.

[0138] (J) Coal is pulverized and dried by a coal pulverizer to obtain pulverized coal, which is stored in a pulverized coal storage tank and sent to a pulverized coal-heat medium mixer through a pulverized coal screw conveyor. The pulverized coal sent to the pulverized coal-heat medium mixer is 6000Kg / h.

[0139] (A) In the pulverized coal-heat medium mixer, mix the pulverized coal obtained in step (J) with the high-temperature gas obtained in step (E) to heat and pyrolyze the pulverized coal, and send the pyrolysis product into the semi-coke separator. The pyrolysis temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com