External resonant cavity semiconductor laser and method for manufacturing same

A resonant cavity and laser technology, applied in the field of lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

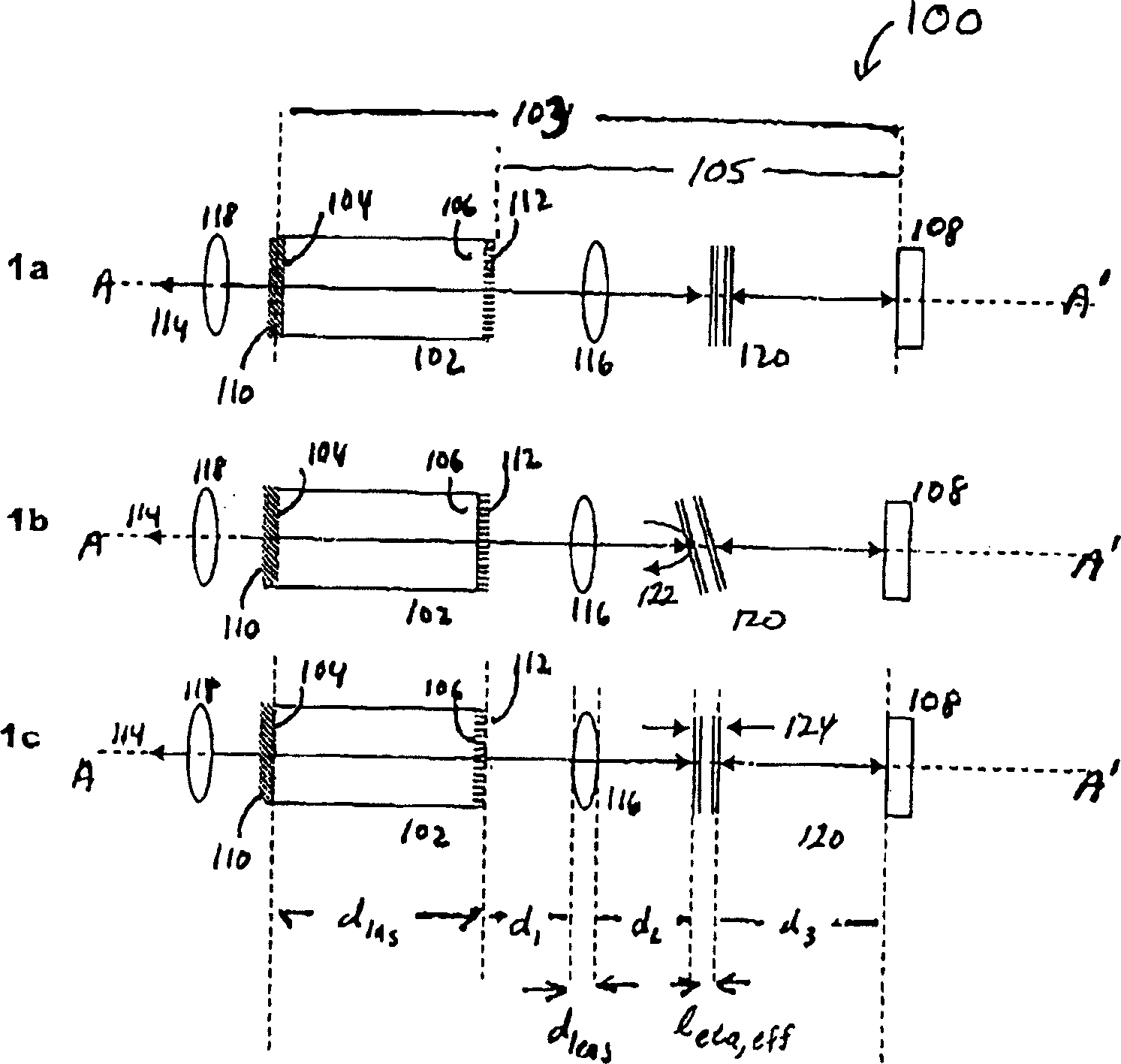

[0071] A notable feature of the present invention is the compactness of the micromachined etalon and the correspondingly shortened optical path length of the optical cavity 103 allows for a simpler method of more optimized mode spacing and mode selection. These aspects of the invention are further exemplified in the following modeled and simulated examples.

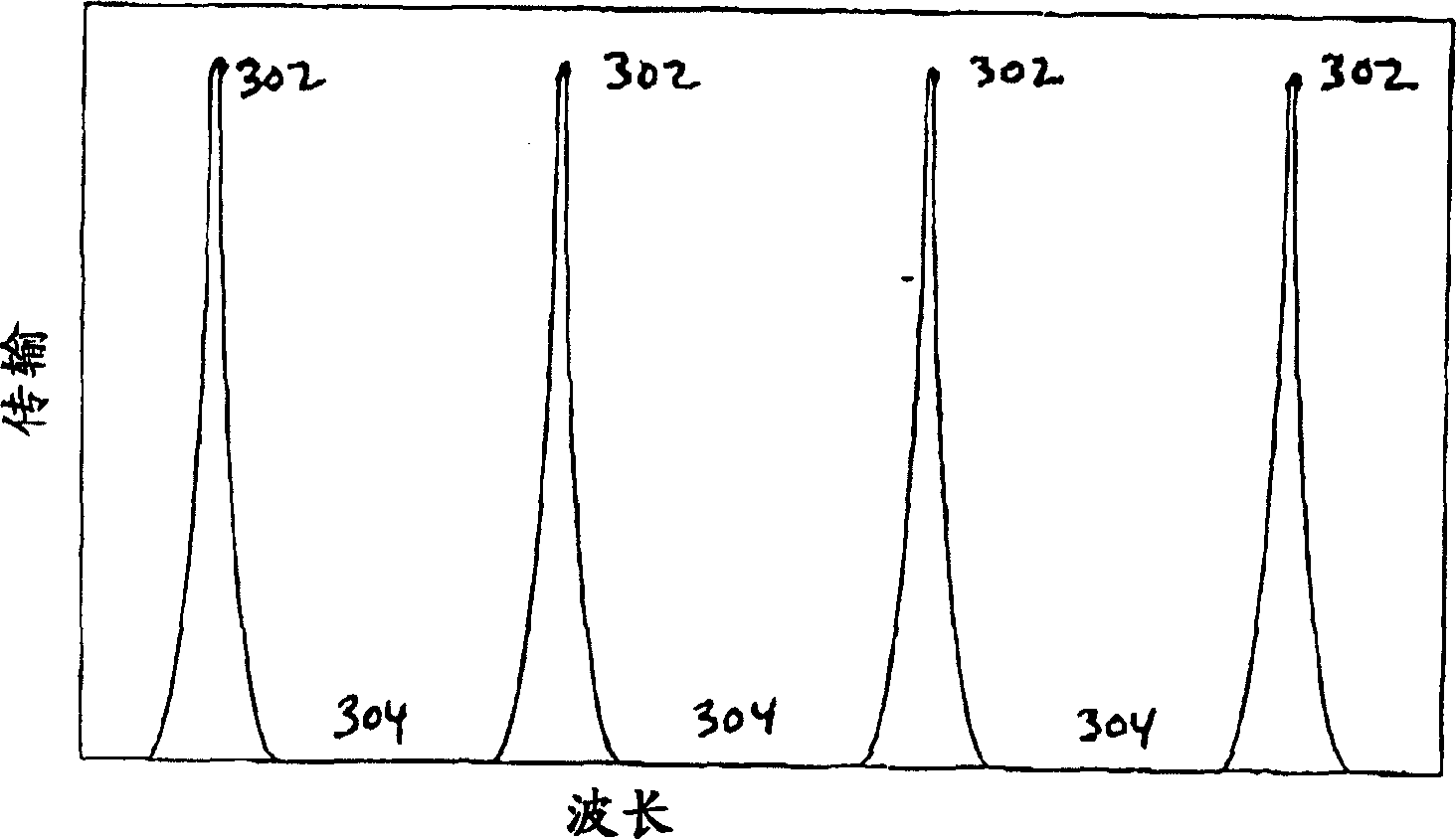

[0072] Figure 8a Shows the effective total optical resonance cavity length l for 24 mm in the spectral range centered at 1550 nm wavelength cav,eff Computational Comb Shapes of Longitudinal Wavelength Modes. The mode spacing is about 0.5 nm. Figure 8b The results of similar simulations for reducing the total optical path length of the laser resonator to 12 mm are shown. It is expected that the mode spacing increases to about 1 nm from that of the first embodiment. Figure 8a and 8b The effect of the length of the optical resonator on the mode spacing is illustrated, and a shorter optical resonator leads to a wider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com