Gain optical fiber for outputting specific single-mode lasers

A gain fiber and a single technology, applied in the direction of multi-layer core/cladding optical fiber, cladding optical fiber, optical waveguide light guide, etc., can solve the problems of fiber segmental gain doping, complex scheme, unfavorable implementation, etc., to achieve effective Utilize and suppress the effect of amplifying spontaneous emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

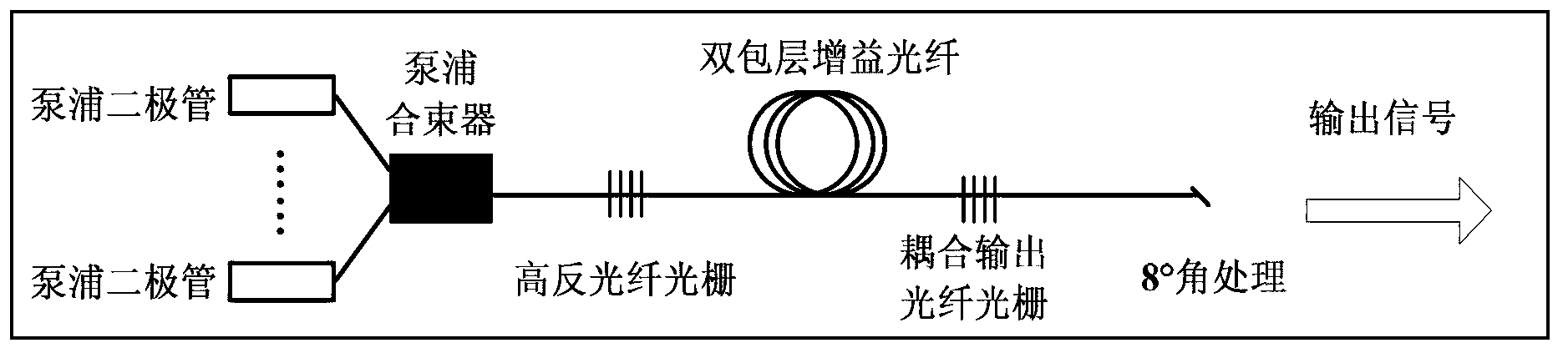

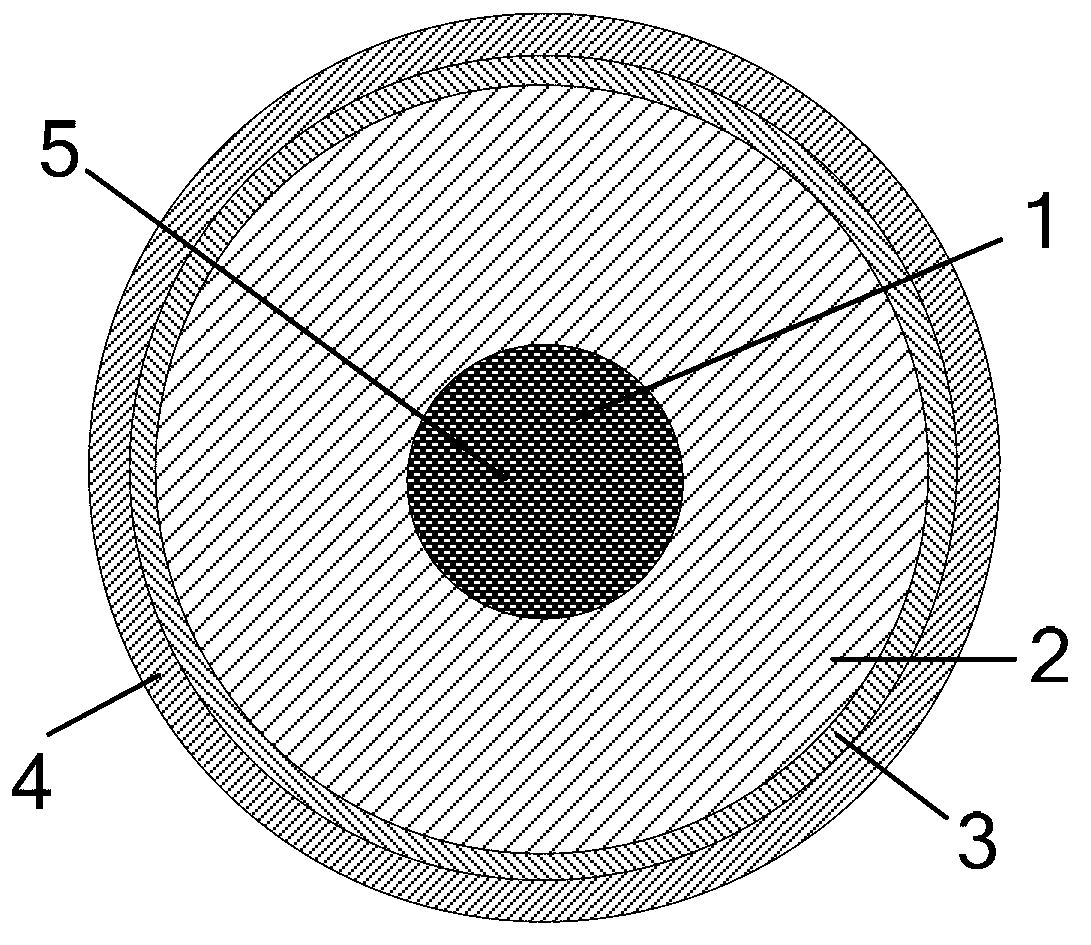

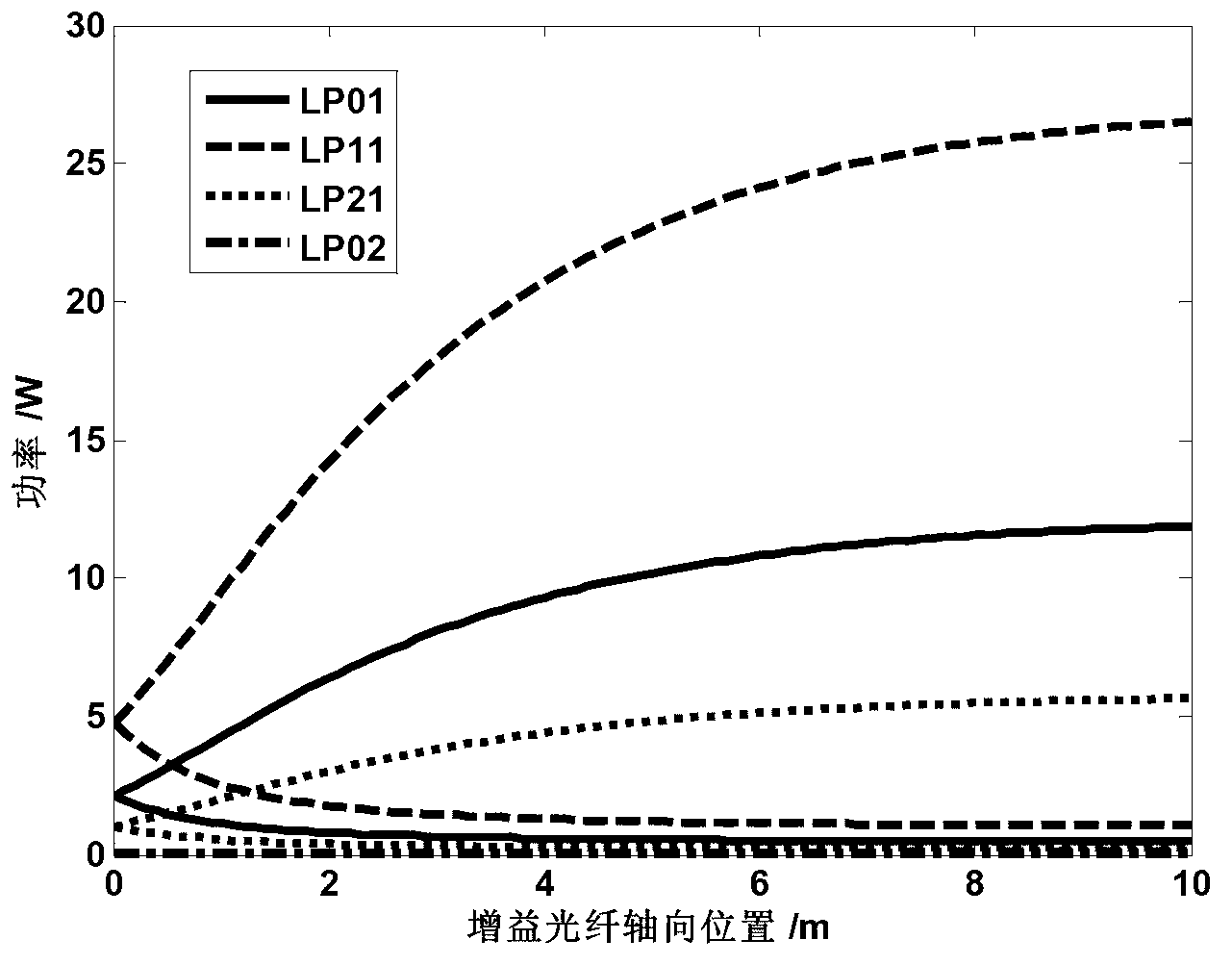

[0035] a kind of like Figure 4 The shown gain fiber of the present invention for outputting a specific single-mode laser is a large-mode-field double-clad gain fiber for outputting LP 01 Mode laser (that is, fundamental mode laser), the gain fiber includes a core 1, an inner cladding 2, an outer cladding 3 and a coating 4, the diameter of the core 1 is 30 μm, the outer diameter of the inner cladding 2 is 400 μm, and the outer cladding 3 It is the same medium as the coating layer 4, and the outer diameter of the coating layer 4 is 550 μm (both the inner diameter and the outer diameter in the present invention refer to the diameter); the refractive index n of the fiber core 1 1 is 1.4596, the refractive index n of the inner cladding layer 2 2 is 1.4584, the refractive index n of the outer cladding 3 3 is 1.3839, and the refractive index distribution curve 7 is a step type (see Figure 5 ); the numerical aperture of the core 1 relative to the inner cladding 2 is 0.06, and the...

Embodiment 2

[0040] a kind of like Figure 7 The shown gain fiber of the present invention for outputting a specific single-mode laser is a large-mode-field double-clad gain fiber for outputting LP 11 mode laser, the gain fiber includes a core 1, an inner cladding 2, an outer cladding 3 and a coating 4, the diameter of the core 1 is 30 μm, the outer diameter of the inner cladding 2 is 400 μm, the outer cladding 3 and the coating 4 are In the same medium, the outer diameter of the coating layer 4 is 550 μm; the refractive index n of the core 1 1 is 1.4596, the refractive index n of the inner cladding layer 2 2 is 1.4584, the refractive index n of the outer cladding 3 3 is 1.3839, and the refractive index distribution curve 7 is a step type (see Figure 8 ); the numerical aperture of the core 1 relative to the inner cladding 2 is 0.06, and the numerical aperture of the inner cladding 2 relative to the outer cladding 3 is 0.46. Such as Figure 7 As shown, this example is used to output L...

Embodiment 3

[0044] a kind of like Figure 10 The shown gain fiber of the present invention for outputting a specific single-mode laser is a large-mode-field double-clad gain fiber for outputting LP 21 mode laser, the gain fiber includes a core 1, an inner cladding 2, an outer cladding 3 and a coating 4, the diameter of the core 1 is 30 μm, the outer diameter of the inner cladding 2 is 400 μm, the outer cladding 3 and the coating 4 are In the same medium, the outer diameter of the coating layer 4 is 550 μm; the refractive index n of the core 1 1 is 1.4596, the refractive index n of the inner cladding layer 2 2 is 1.4584, the refractive index n of the outer cladding 3 3 is 1.3839, and the refractive index distribution curve 7 is a step type (see Figure 11 ); the numerical aperture of the core 1 relative to the inner cladding 2 is 0.06, and the numerical aperture of the inner cladding 2 relative to the outer cladding 3 is 0.46. Such as Figure 10 As shown, this example is used to outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com