Micro-fiber probe loss modulation-based polymer bottle micro-cavity single-mode laser component

A technology of laser components and polymers, applied in laser parts, lasers, electrical components, etc., can solve problems such as large scattering loss, and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

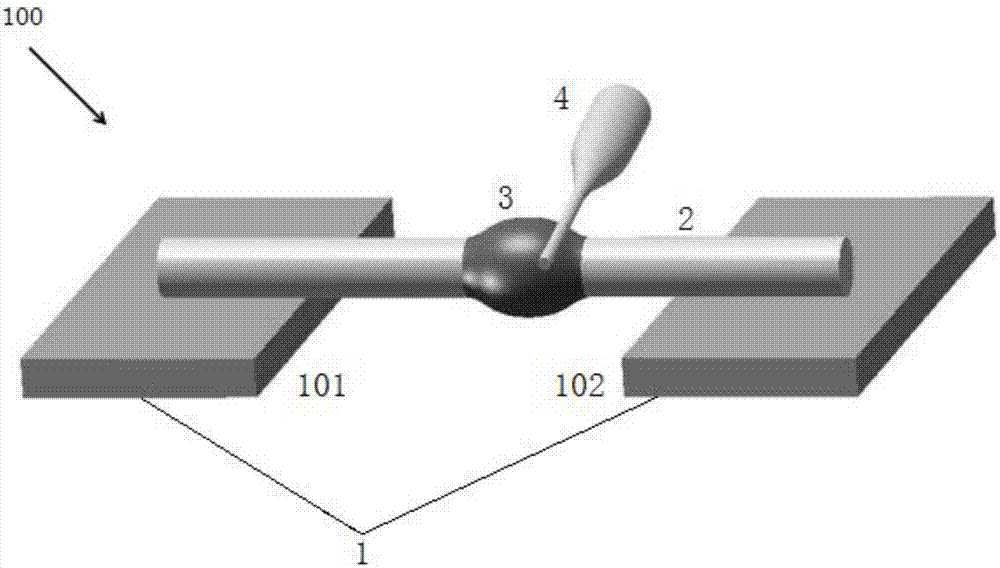

[0038] The preparation method of the polymer bottle microcavity single-mode laser element 100 based on the micro-fiber probe loss modulation of the present embodiment includes the following steps:

[0039] Step 1, using a carbon dioxide laser as a heat source, drawing an ordinary single-mode optical fiber by high temperature stretching method, and preparing a micro optical fiber 2 and a pump optical fiber probe 4;

[0040] Step 2, placing the two ends of the micro-optical fiber 2 on the first slide 101 and the second slide 102, and the middle section is suspended;

[0041] Step 3, dissolving the laser gain substance in a polymer organic solvent and mixing it with a high-viscosity resin and a curing agent, and then oscillating evenly on a circular oscillating shaker to obtain a resin solution;

[0042] Step 4, immersing the pump fiber optic probe 4 in the resin solution prepared in step 4 and quickly extracting to obtain micro-droplets;

[0043] Step 5, under the optical micro...

Embodiment 1

[0050] The preparation method of the single-mode laser element is as follows:

[0051] Step 1, using a carbon dioxide laser as a heat source, drawing a common single-mode optical fiber by a high-temperature drawing method, and preparing a micro-fiber 2 with a diameter of 3.2 μm and a pumping optical fiber probe 4 with a tip diameter of 1.1 μm;

[0052] Step 2, placing the two ends of the micro-optical fiber 2 on the first slide 101 and the second slide 102 with an interval of 2000 μm, and the middle section is suspended;

[0053] Step 3, dissolve the R6G laser dye in chloroform and mix it with high-viscosity epoxy resin and curing agent, and then oscillate evenly on a circular oscillating shaker to prepare an epoxy resin solution uniformly doped with R6G laser dye. R6G laser dye is in The mass concentration in epoxy resin solution is 2.5%, and the volume ratio of chloroform and high viscosity epoxy resin is 1:10;

[0054] Step 4, immersing the pump fiber optic probe 4 with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com