High coupling efficiency electric injection integration silicon-based laser

A high-coupling and laser technology, applied in the structure of optical waveguide semiconductors, the structure of active regions, etc., can solve the problems of large optical coupling loss and small alignment tolerance, and achieve high-efficiency output, compact structure, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

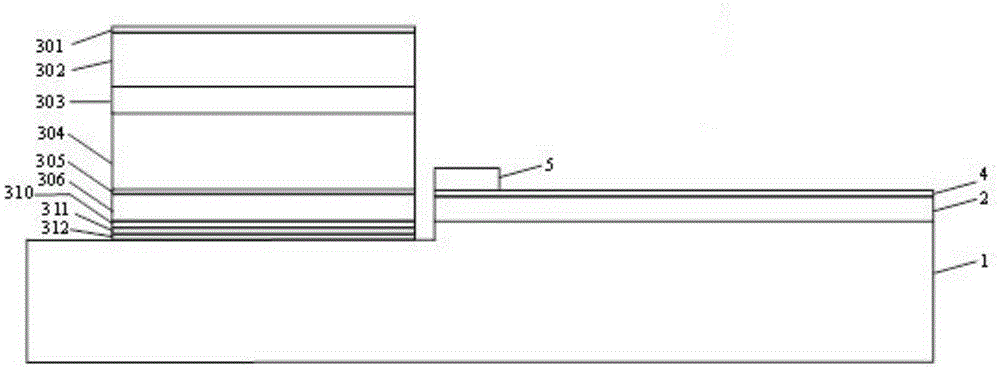

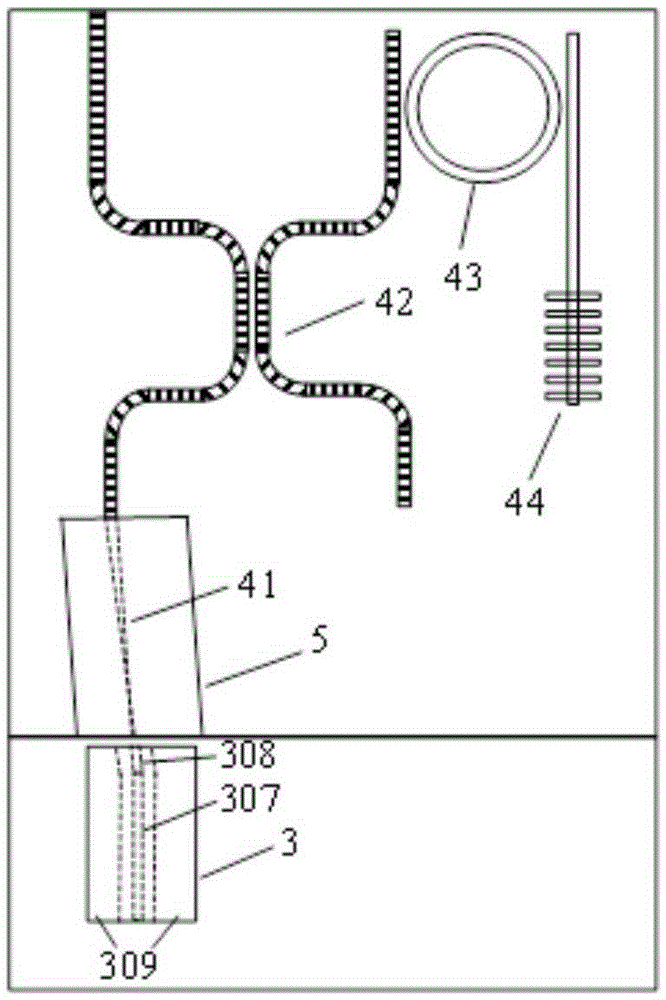

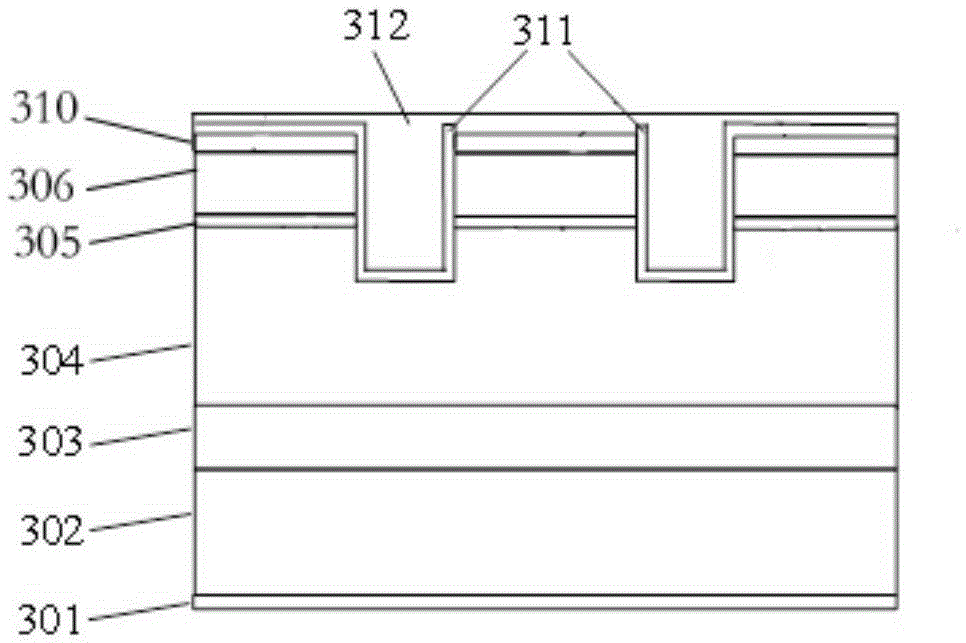

[0047] The low refractive index layer 5 covered on the speckle converter 41 is SiO 2 , both width and thickness are 6 μm. Semiconductor active chips have the following two setups:

[0048] One is a typical commercial semiconductor active chip. The total thickness of the waveguide on both sides of the active layer is 0.6 μm, the width of the ridge is 5.5 μm, and the output near-field distribution is as follows: Figure 4 shown. The near field is in the direction of the fast axis and the slow axis 1 / e 2 The widths are 1.01μm and 5.09μm respectively, which are elliptical spots;

[0049] The other is a large-mode semiconductor active chip, the thickness of the output waveguide 308 near the active layer is 5 μm, the width of the ridge portion 307 is 5.5 μm, and the output near-field distribution is as follows: Figure 5 shown. The near field is Gaussian-like distribution in both the fast axis and the slow axis direction, and its 1 / e 2 The widths are 4.07 μm and 4.88 μm, respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com