Pressure control valve for hydraulic actuation assembly

A pressure control and component technology, applied in the direction of fluid pressure control without auxiliary power, fluid pressure actuation system components, control valves, etc., can solve the problem of insufficient fluid viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

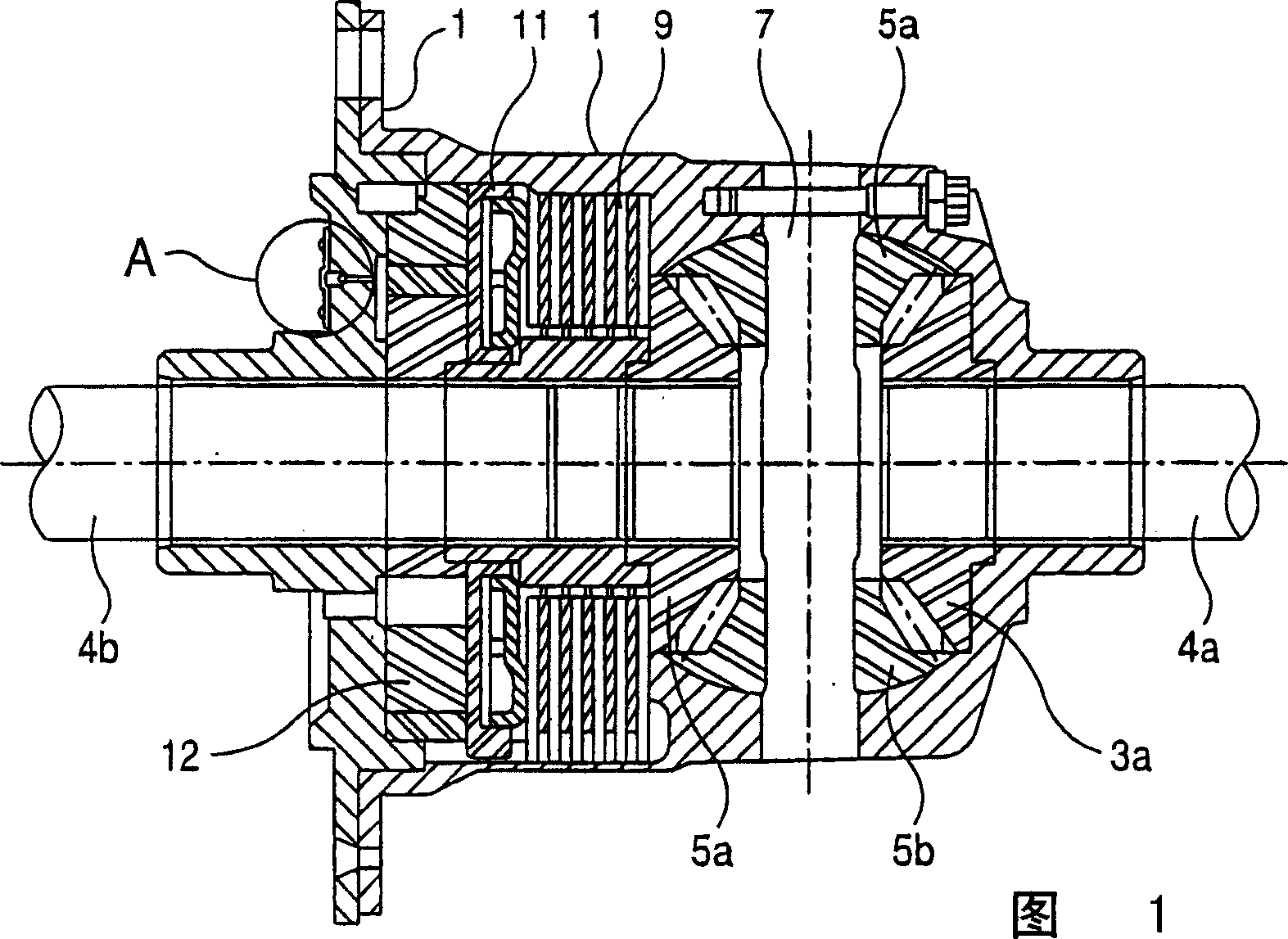

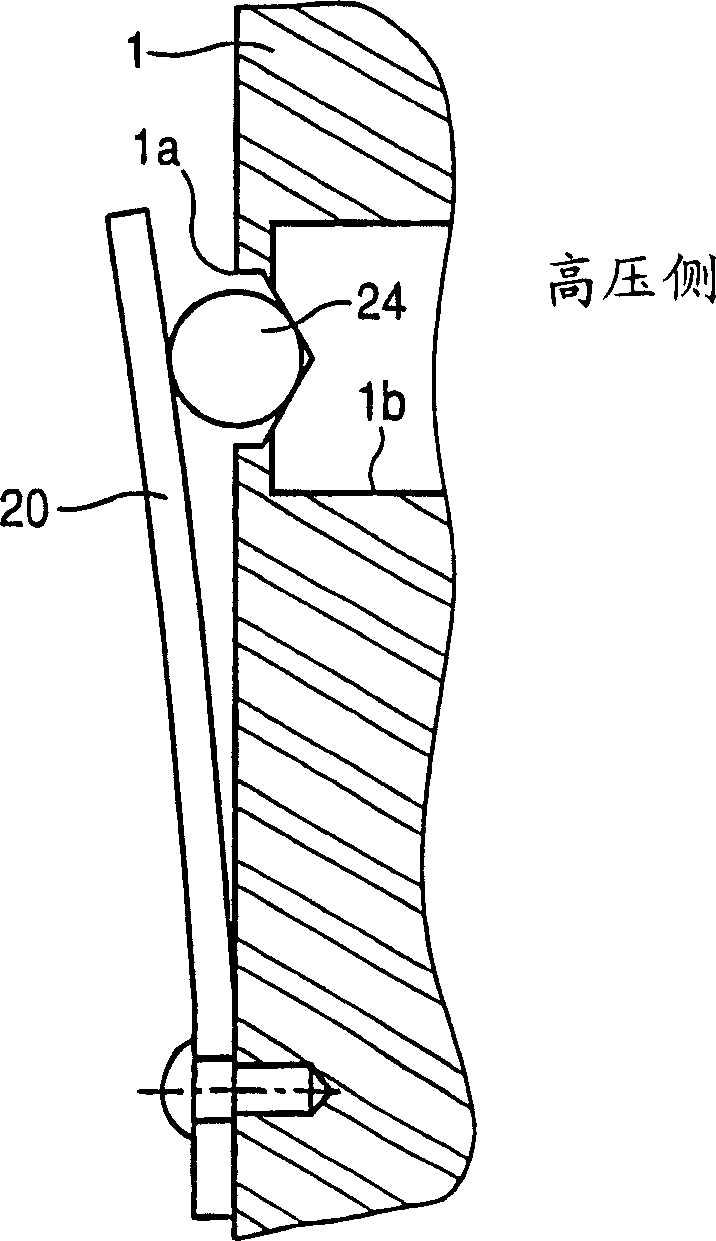

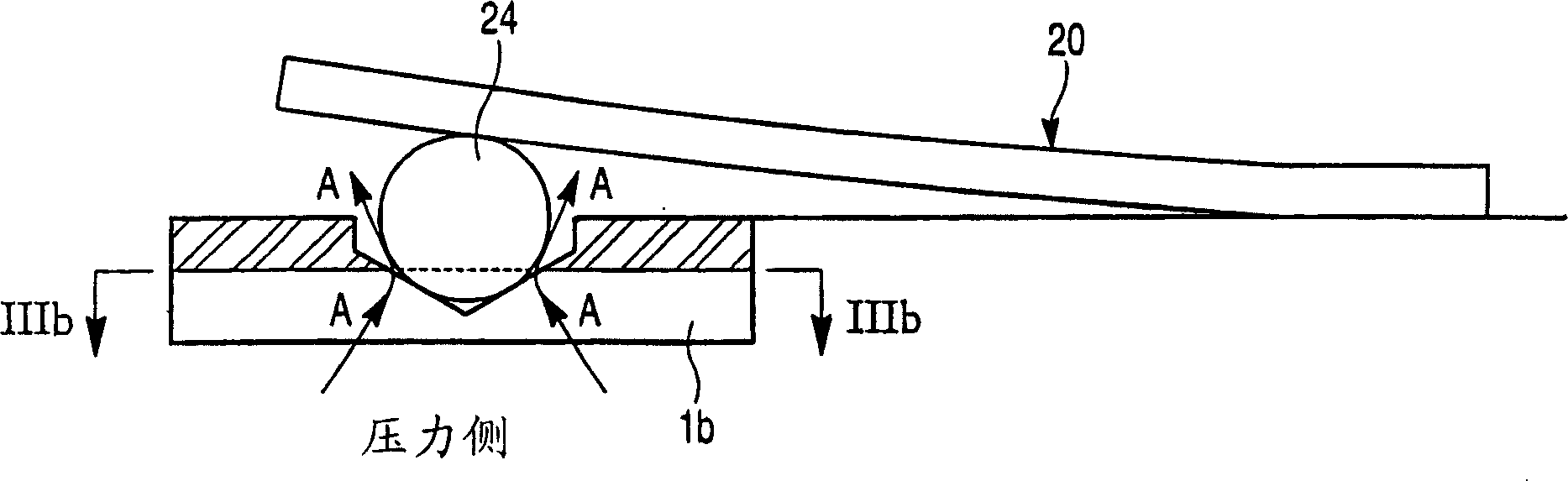

[0019] FIG. 1 is a sectional view of a limited slip differential using a pressure control valve of the present invention. However, it is to be understood that while the present invention is described with respect to a speed sensitive limited slip differential, the present invention is equally applicable to various torque couplings using hydraulic pump systems, and other hydraulic couplings for transmission. A differential case 1 driven by ring teeth (not shown) accommodates a pair of side gears 3a, 3b, a pair of pinion gears 5a, 5b and a pinion shaft 7 to allow for communication between a pair of opposing output shafts 4a, 4b. Speed difference, as generally known in the art. An anti-slip device in the form of a clutch unit 9 is provided between the side gear 3 b and the differential case 1 . A plurality of friction discs are alternately splined to the side gear 3b and the differential case 1 . A hydraulically actuated piston 11 arranged in the piston chamber serves to comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com