Screw-thread steel three-parameter on-line measuring system

A measurement system and rebar technology, applied in the direction of measurement devices, instruments, optical devices, etc., to meet high-quality requirements, reduce labor intensity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

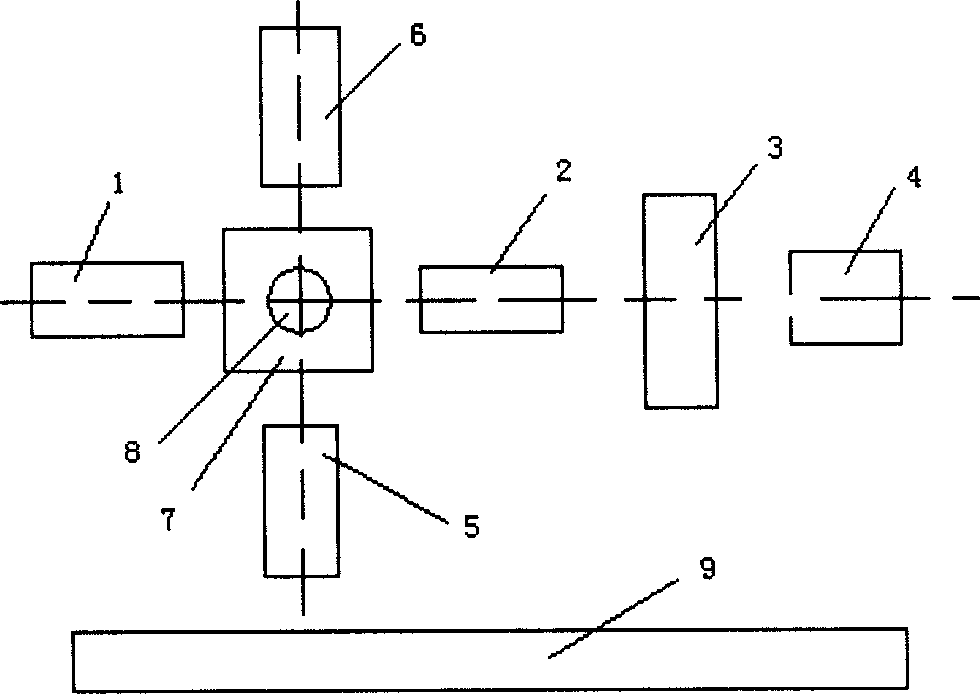

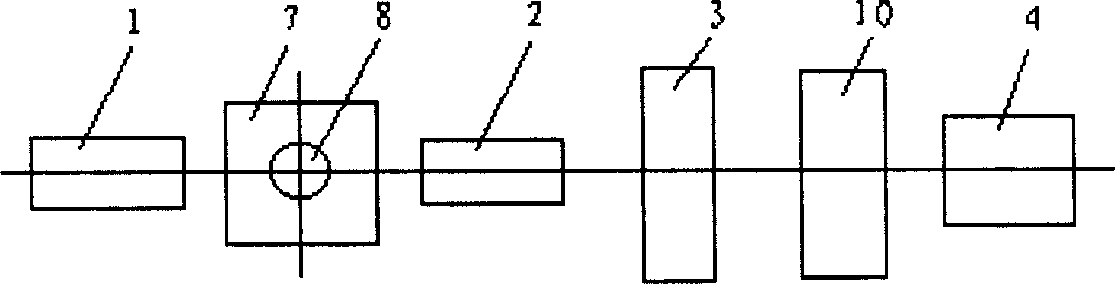

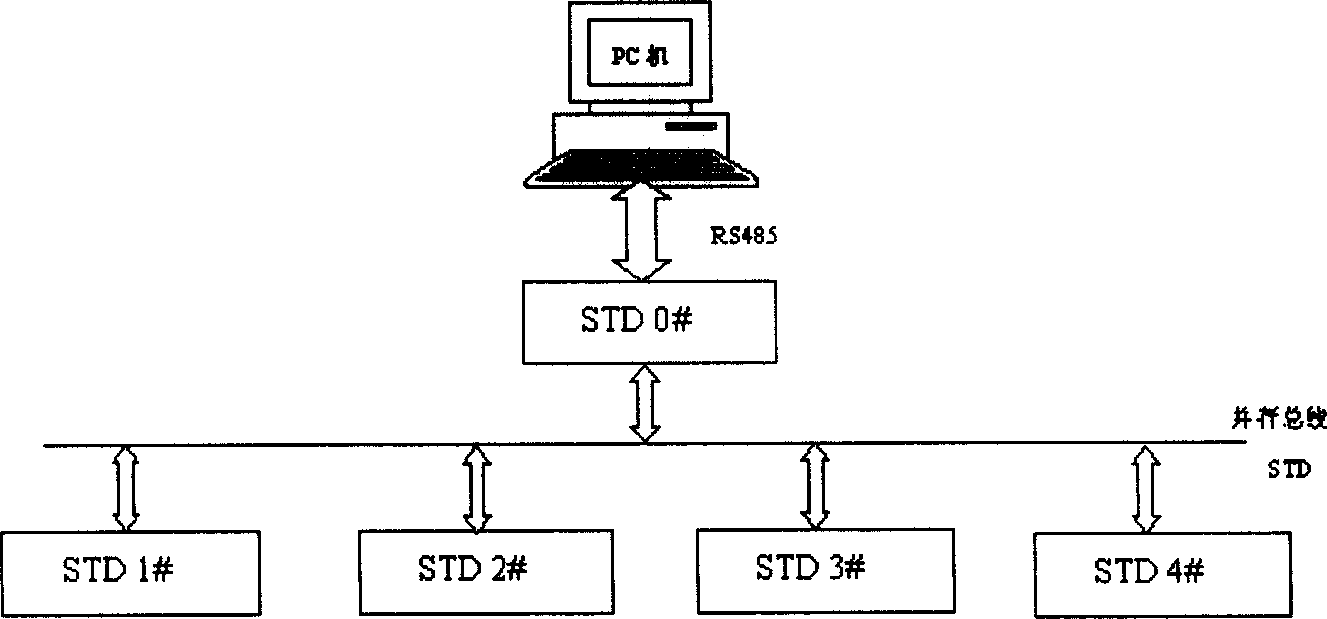

[0018] Such as figure 1 with figure 2 As shown, the present invention consists of a linear array CCD measuring instrument for measuring the height of the longitudinal rib, a photoelectric aiming optical projector for measuring the inner diameter and the height of the transverse rib, a computer control system, a bracket and a guide part 9. Among them, the photoelectric aiming optical projector is composed of a light source 1, a measuring head 7, an imaging system 2, and a photoelectric aiming device 3. The parallel light generated by the light source illuminates the measured piece inside the measuring head, and its projection is amplified by the imaging system to clearly The measurable image is imaged on the projection screen, then targeted and measured by the photoelectric aiming device, and the measured data is input into the computer for processing. The linear array CCD measuring instrument part is composed of a CCD light source 5, a measuring head 7 (8 is the measuring in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com