U-shape isochannel repeated extruding apparatus for preparing ultrafine crystal material

A technology of repeated extrusion and ultra-fine grain, applied in the field of material processing, can solve the problems of small upsetting and small deformation, and achieve the effects of wide application, easy processing and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

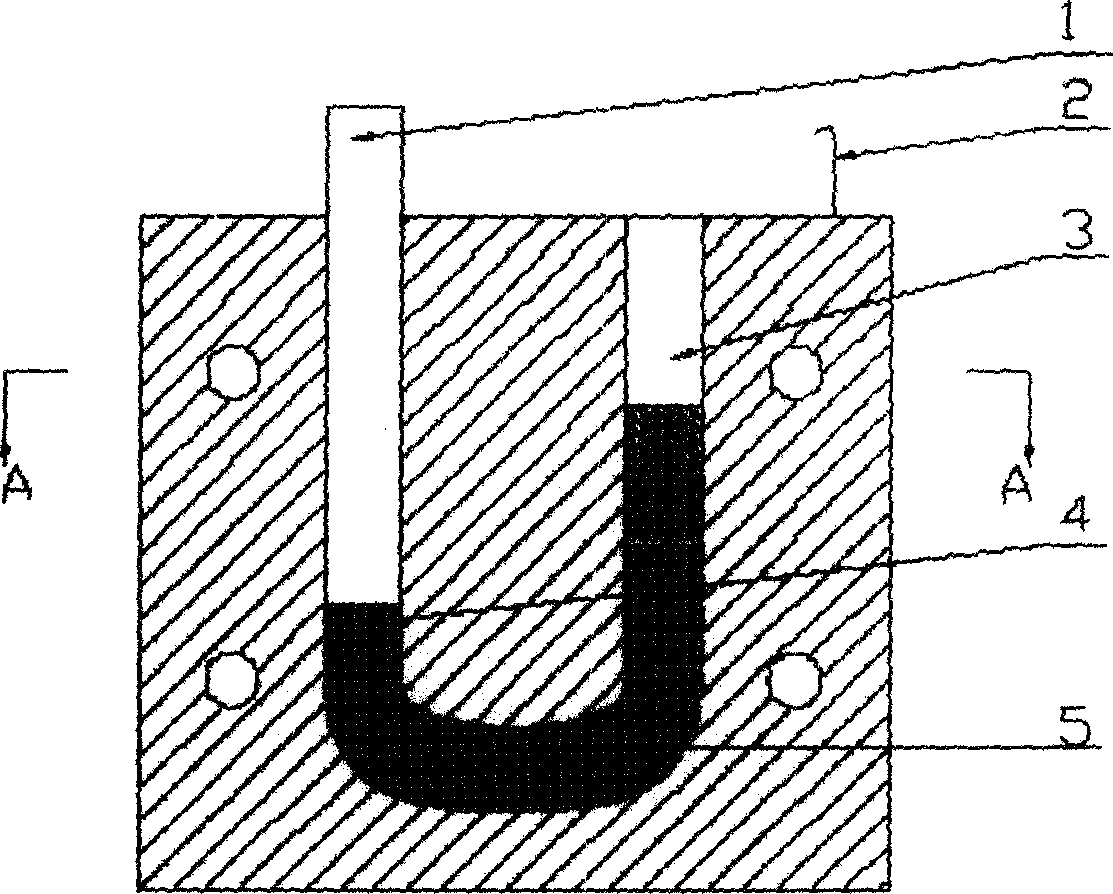

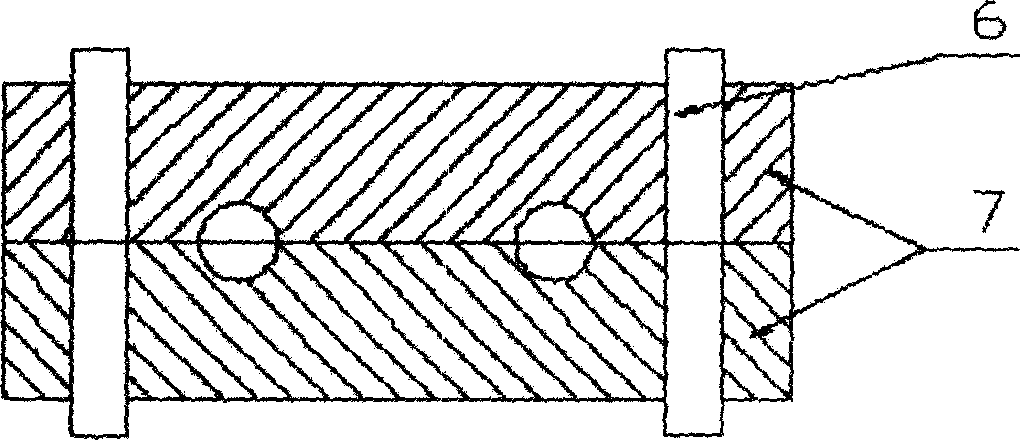

[0010] like figure 1 And shown in Fig. 2, the present invention comprises: extrusion bar 1, handle 2, right die cavity 3, left die cavity 4, arc die cavity 5, bolt 6, die 7. The connection relationship is: the die 7 is symmetrically divided into two halves from the center line, and the left die cavity 4, the right die cavity 3 and the arc-shaped die cavity 5 are arranged on the parting surface. The arc cavity 5 is connected, the left and right cavity 4, 3 have the same cross-sectional area, the same shape, the center lines are parallel to each other, the shape is square or circular, and the arc cavity 5 has the same cross-sectional area as the left and right cavity 4, 3. Equal and same shape, smooth transition with left and right die cavities 4, 3, two halves of die rely on bolt 6 to combine U-shaped extruded equal-section channel, extrusion rod 1 is above the U-shaped extruded equal-sectional channel, passes through guide rail Or the guide of the rotating device can freely e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com