Washing machine with variable-frequency drive

A variable frequency drive, washing machine technology, applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of low efficiency, high energy consumption of washing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

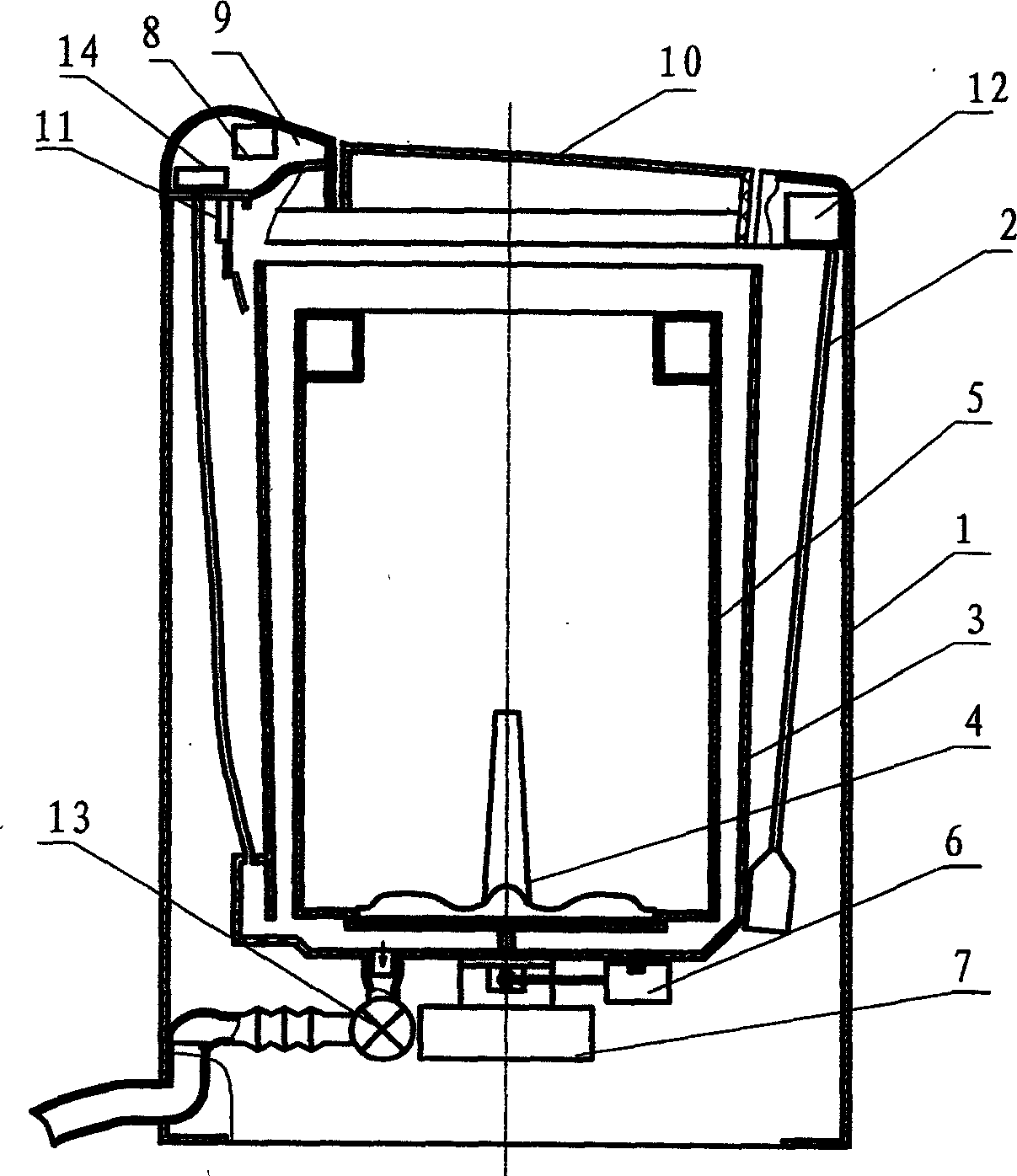

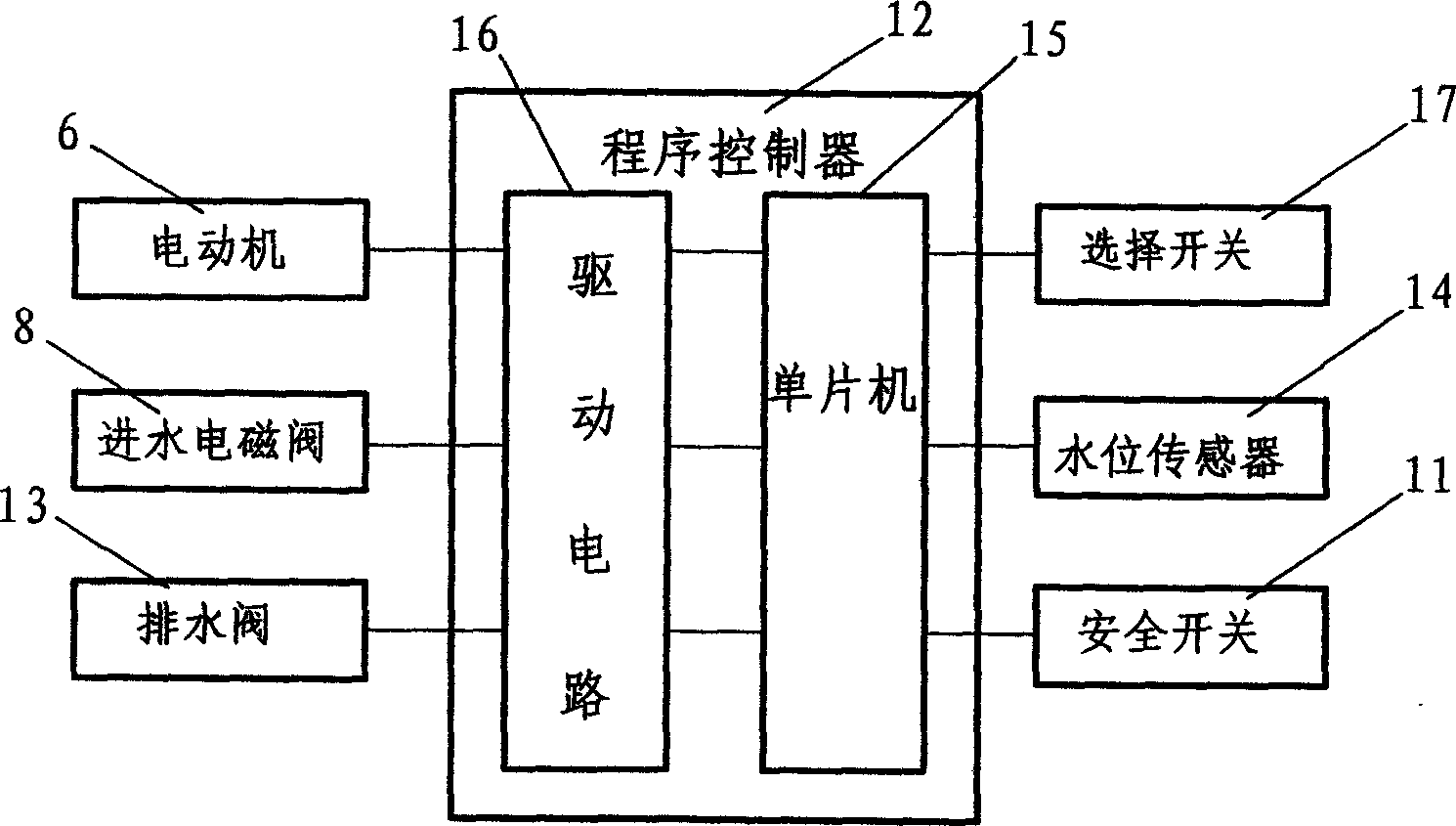

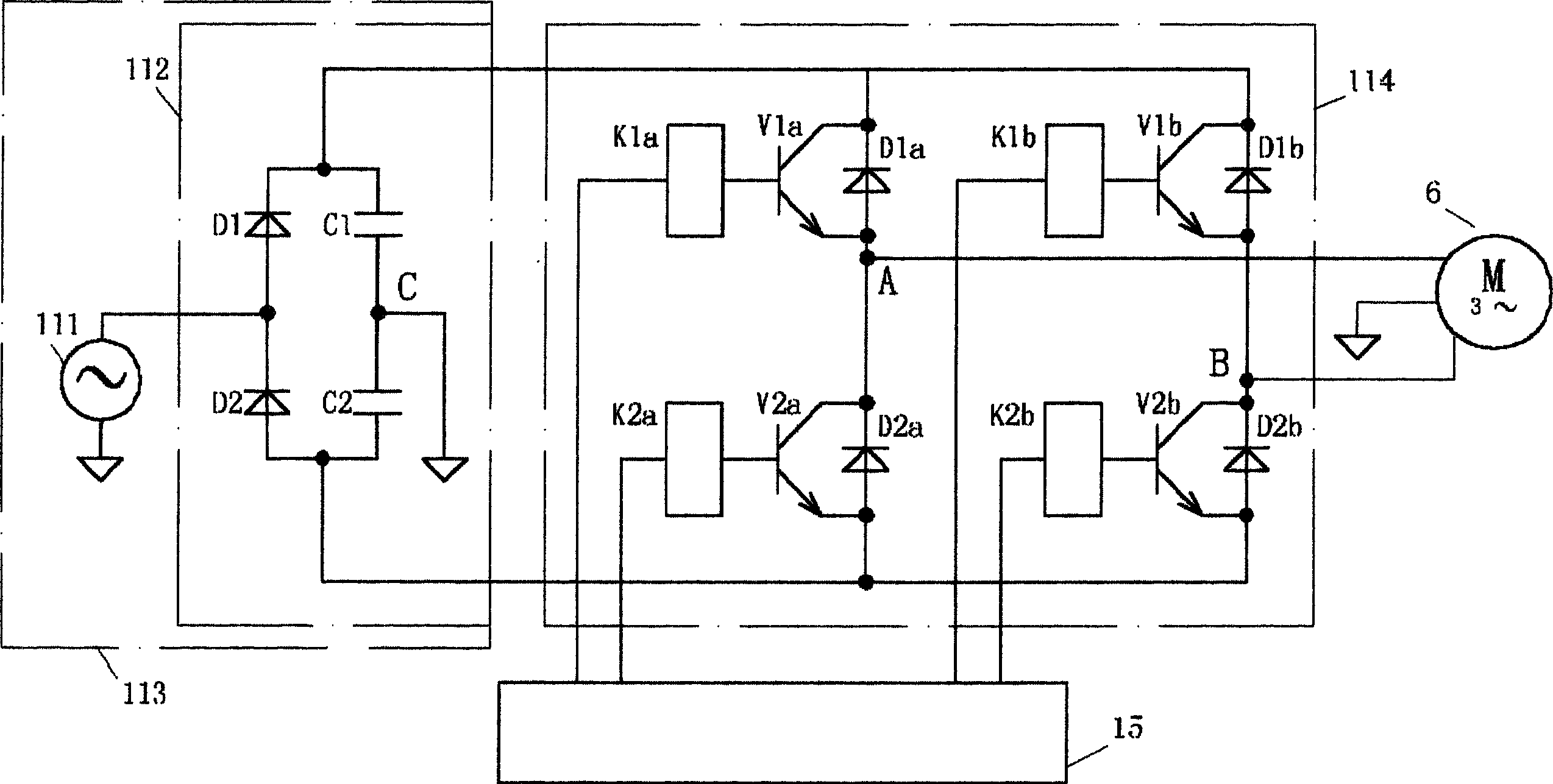

[0015] The overall structure of the fully automatic washing machine in the embodiment of the present invention is as follows: figure 1 shown. In the outer box body 1 arranged on the base, a water bucket 3 is suspended freely through a suspender 2, and a washing and dewatering tank 5 with a rotary agitator 4 at the bottom is freely rotatable in the water bucket 3. The motor 6 and the tractor drain valve 13 which drive the agitator 4 or the washing and dewatering tank 5 through the deceleration clutch 7 are installed at the bottom of the water tank 3, and the top cover 9 is installed on the outer box body 1 and the water tank 3, and the top cover 9 The machine cover 10 that can be opened and closed freely is housed on it, and the program controller 12 and the water inlet electromagnetic valve 8 that the water level sensor 14, receives sensing signal and controls electrical appliances such as motor 6 are installed in the washing machine top cover 9. A safety switch 11 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com