Dynamic compounding controller and method

A control device and dynamic technology, applied in the direction of electric controller, adaptive control, computer control, etc., can solve the problems of high cost, poor integration, and inability to meet modern operations, and achieve enhanced integration, flow detection and control Real-time, the effect of improving the adaptability of the device environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

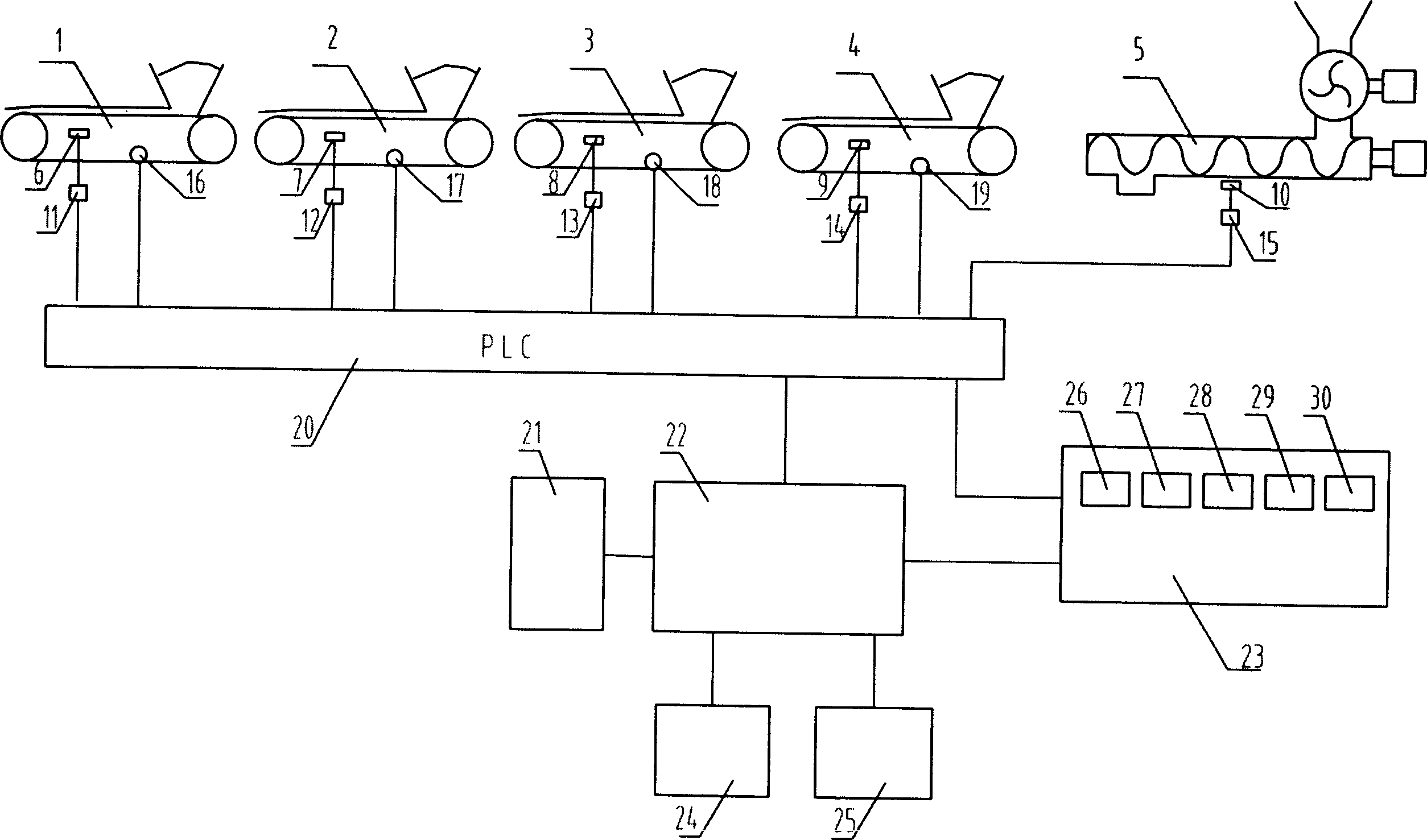

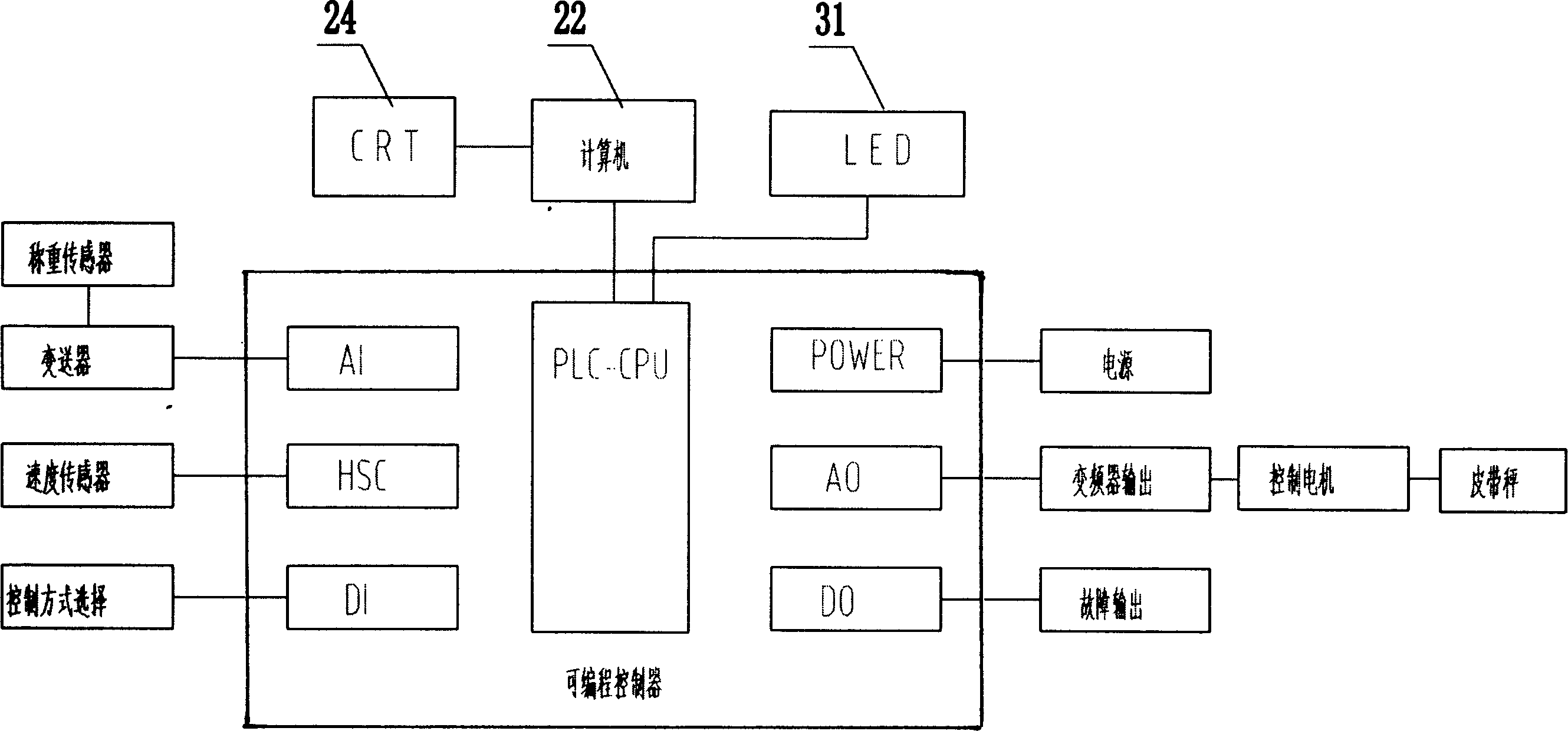

[0031] Dynamic batching control device implements standardized communication, modularized program design, centralized management, decentralized control, upper PC is used as man-machine interface for operation and monitoring, and LED parameter display. The computer 22 is connected to the programmable controller PLC20; the data input end of the programmable controller PLC20 is respectively connected to the signal amplifiers 11, 12, 13, 14 of the load cells 6, 7, 8, 9 of No. 1, 2, 3, and 4 scales And speed sensor 16,17,18,19, the data input end of PLC is also connected with the signal amplifier 15 of the weighing sensor 10 of powder scale 5; The data output end of PLC is respectively connected control No. 1,2,3,4 scale The frequency converters 26, 27, 28, 29 for driving the motors, and the data output end of the PLC are also connected to the frequency converter 30 for controlling the feeding motor of the No. 5 powder scale. The frequency converters 26 , 27 , 28 , 29 , and 30 are ...

Embodiment 2

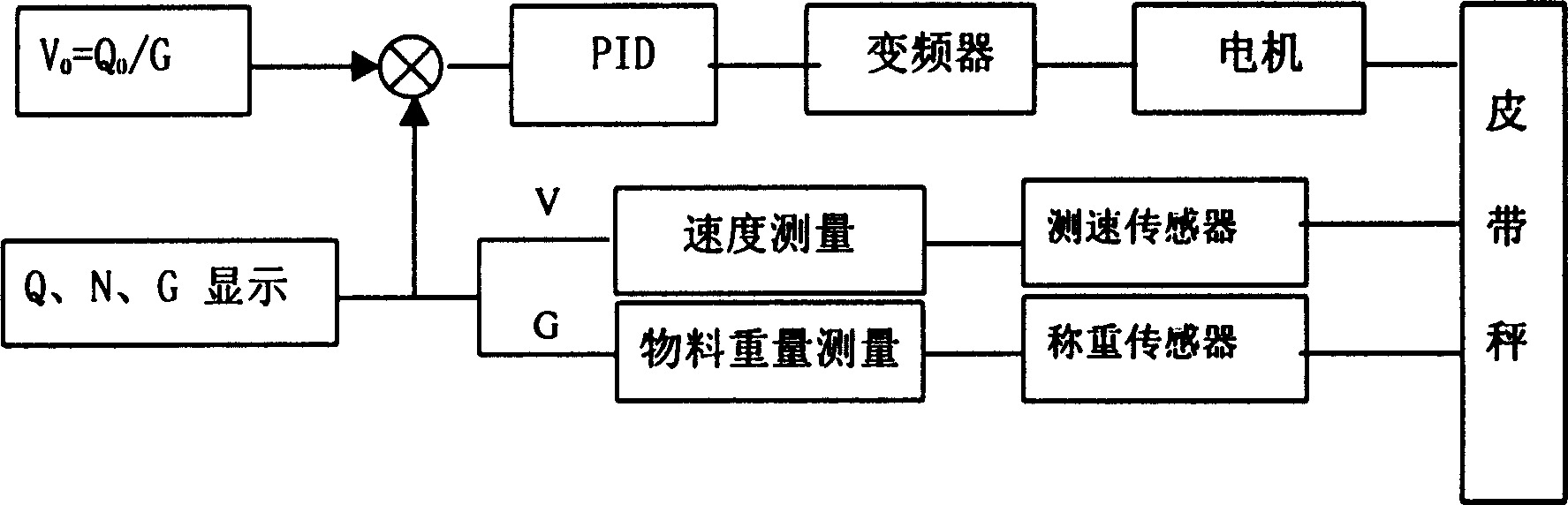

[0035] The dynamic batching control method of embodiment 1 device, by computer 22 through RS-232 communication port and receive and control programmable controller PLC20 data, programmable controller PLC20 dynamically collects the weighing sensor of No. 1, 2, 3, 4 scales The data of the signal amplifier 11,12,13,14 and speed sensor 16,17,18,19 of 6,7,8,9, and the data of the signal amplifier 15 of the weighing sensor 10 of gathering powder scale 5; Through system Required flow Q 0 , system required speed V 0 Compared with the actual flow Q of the system, the actual speed of the system V, the weight of the material G weighed by the load cell, and the actual speed N of the motor, and after data processing, the PLC20 controls the inverters of the drive motors of scales 1, 2, 3, and 4 respectively 26, 27, 28, 29, control the frequency converter 30 of the No. 5 powder scale feeder, so as to control the speed of the drive motor and realize the purpose of dynamic batching quantitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com