Automatic continuous copper foil annealing system

A copper foil and annealing technology, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems that the physical properties of copper foil cannot meet the requirements, and achieve the effect of bright surface, simple structure and neat edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be described further in conjunction with the embodiment in the accompanying drawing:

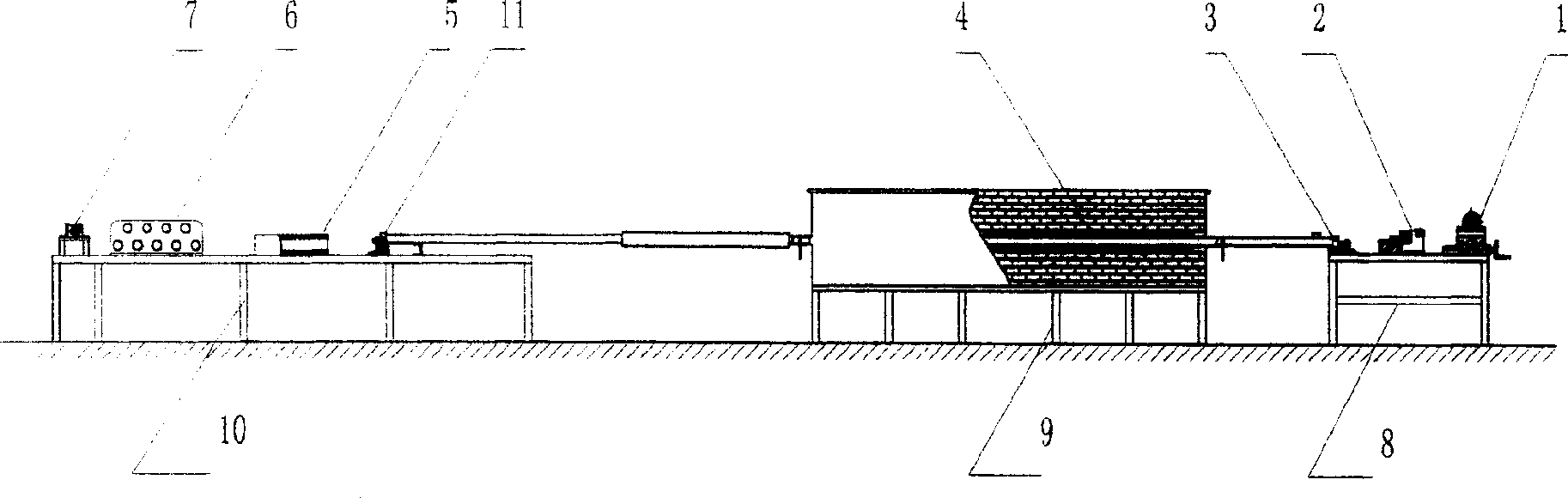

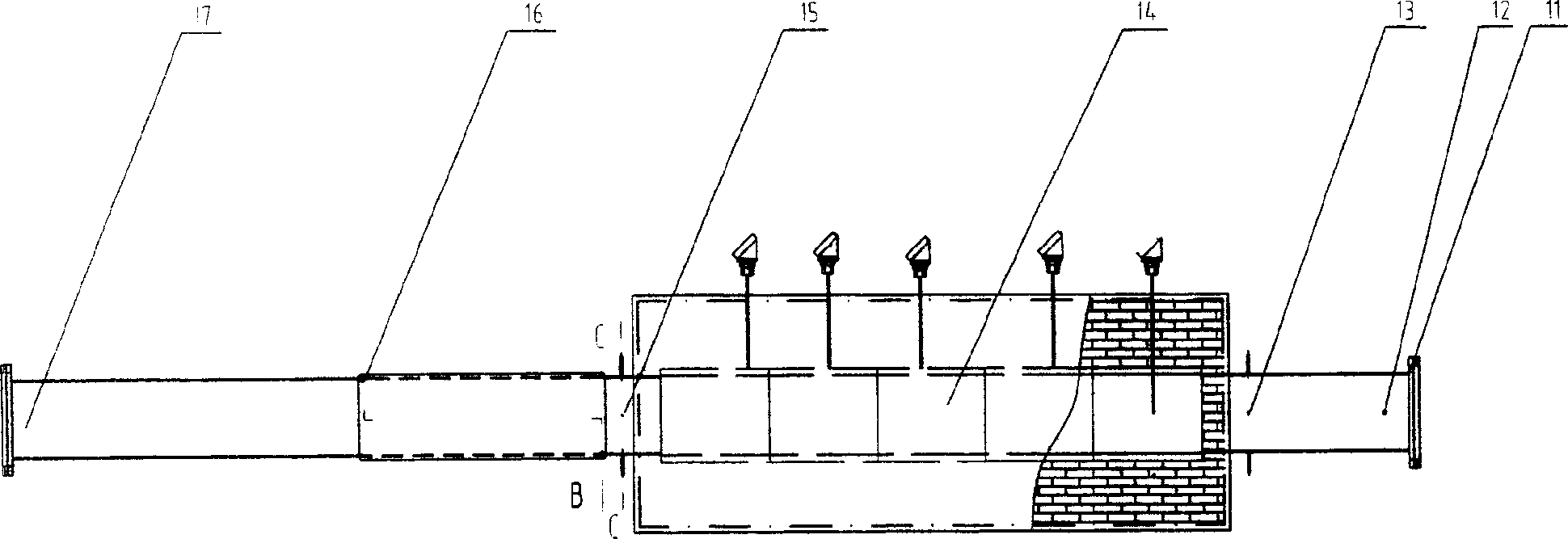

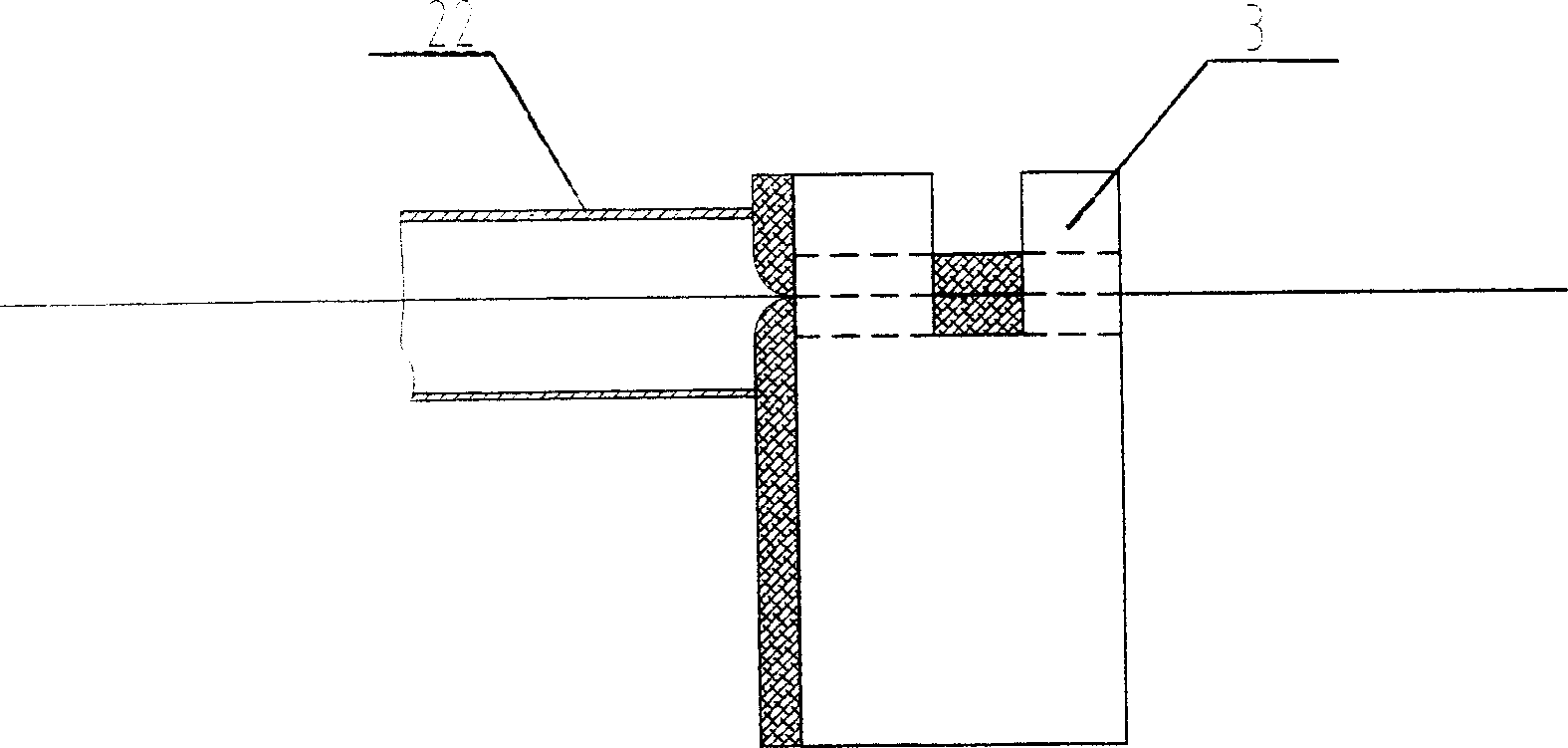

[0015] The present invention mainly consists of a discharge rack 1, a discharge shaft 2, seals 3, 11, a horizontal continuous annealing furnace 4, a dryer 5, a guide roller shaping device 6, a winding device 7, workbenches 8, 10, and a work frame 9 , copper foil inlet 12, first inlet 13 of mixed gas, furnace heating zone 14, air intake zone 15, water jacket cooling zone 16, natural cooling zone 17, thermocouple 18, light refractory material 19, furnace It is composed of a tank shell 20, a furnace tube 21, a furnace tank 22, left and right side plates 23, 27, tracks 24, mounting holes 25, guide rollers 26, magnetic powder couplers 28, and the like.

[0016] The present invention mainly uses the discharging rack 1, the discharging shaft 2, and the seal 3 at one end of the annealing furnace to be placed on the workbench 8 in sequence, the main body of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com