Welding disk vision identifying and positioning system for flexible laser ball implanting machine

A visual identification and positioning system technology, applied in laser welding equipment, welding equipment, electrical components, etc., can solve the problem that cannot meet the development trend of BGA chip miniaturization, high-density I/O number, pad positioning accuracy and repeated positioning Low precision ball planting efficiency, inconvenient popularization, promotion and commercialization, etc., to achieve the effect of reducing precision requirements and the number of sensors, large commercial value, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

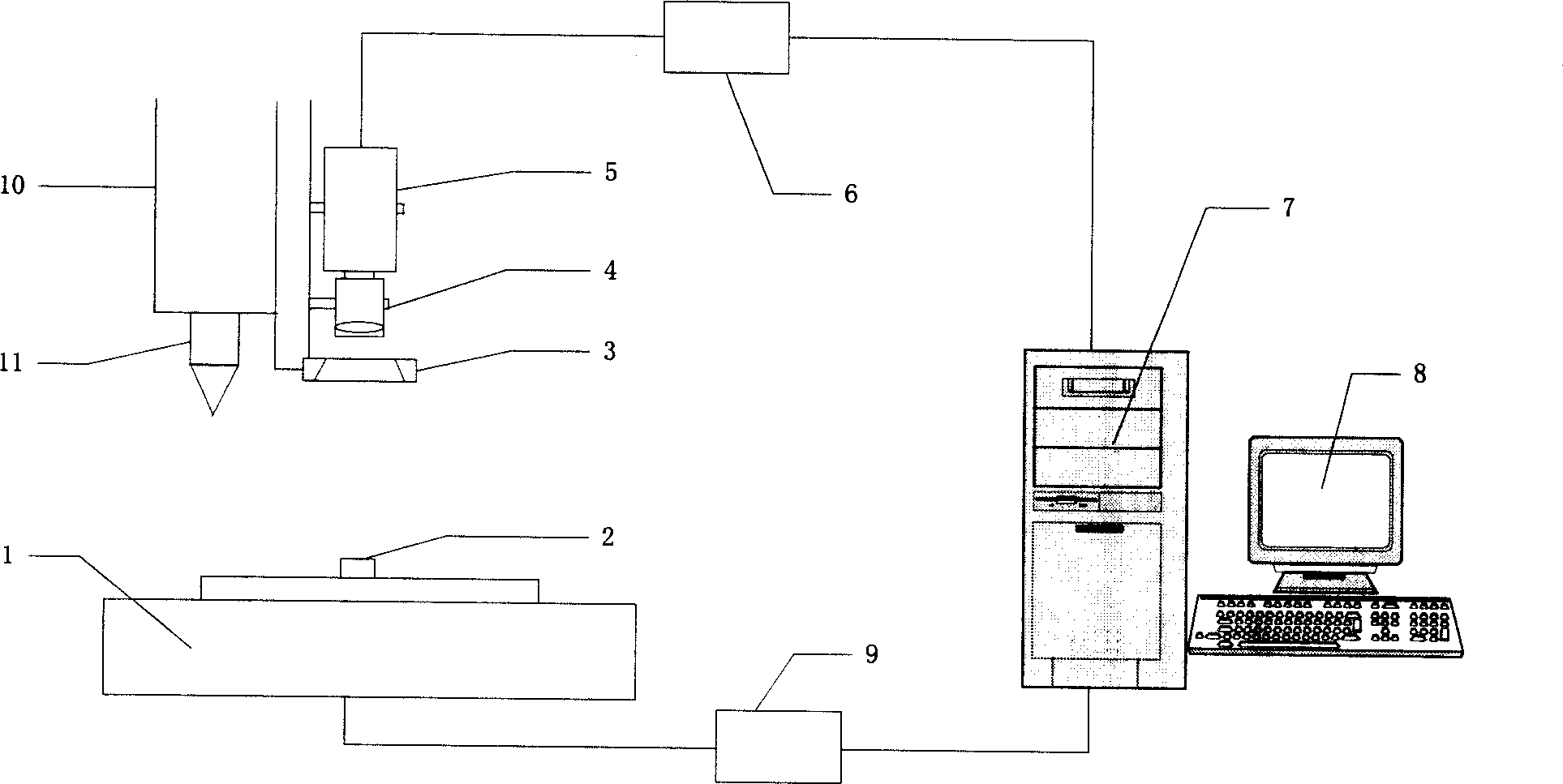

[0008] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0009] The system structure of the present invention is as figure 1 As shown, on the fixed bracket 10 of the ball planting head 11 installed, a CCD camera 5 is installed, the lens 4 is connected with the CCD camera 5 through the C interface, and the lens 4 is fastened on the fixed bracket 10 simultaneously to prevent loosening. When the CCD camera 5 and the lens 4 are fixedly connected to the fixed bracket 10, the central axis and the central axis of the ball planting head 11 should be parallel to each other, and should be as close as possible to each other without interfering with each other. Then, a ring-shaped LED light source 3 is installed directly below the lens 4, the purpose is to avoid the impact of ambient light changes on the later image processing and system positioning accuracy. The type and size of the ring-shaped LED light sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com