CWDM light filter

A technology of optical filter and film layer, which is applied in the field of optical filter and can solve problems such as light leakage or noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now, the CWDM (coarse wavelength division multiplex) filter of the present invention will be further described in detail in conjunction with the accompanying drawings.

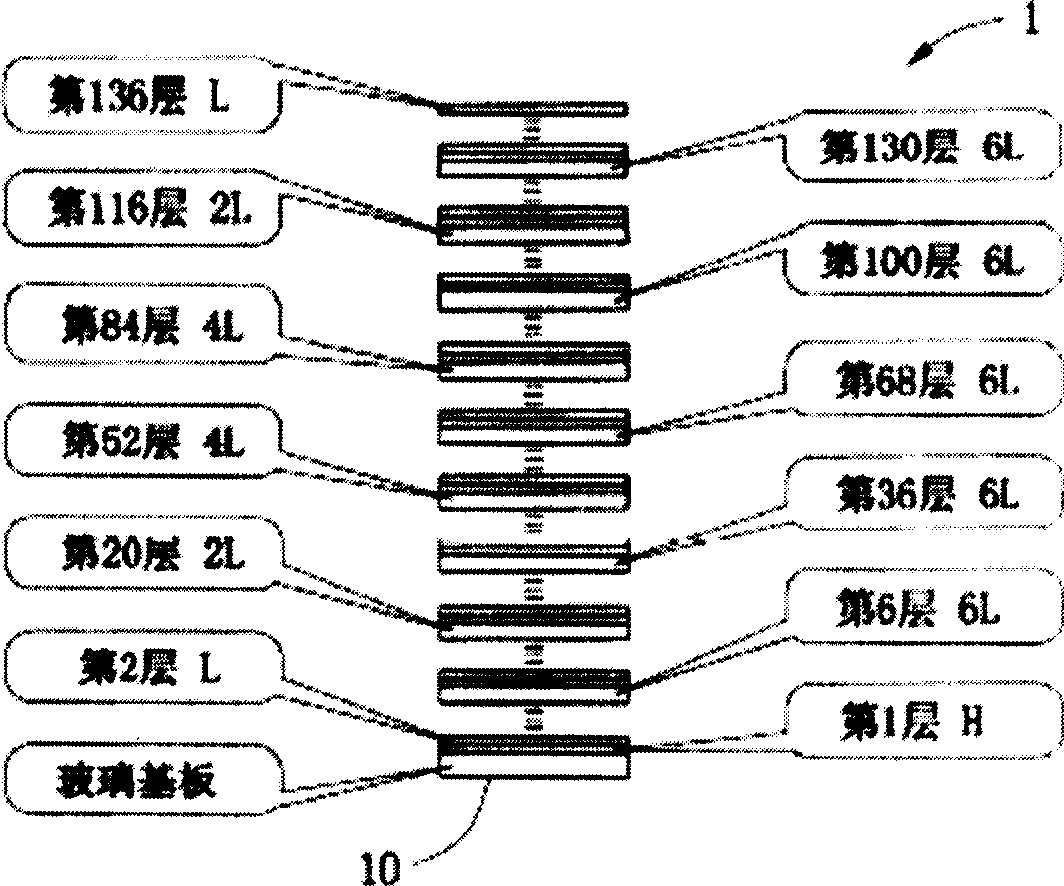

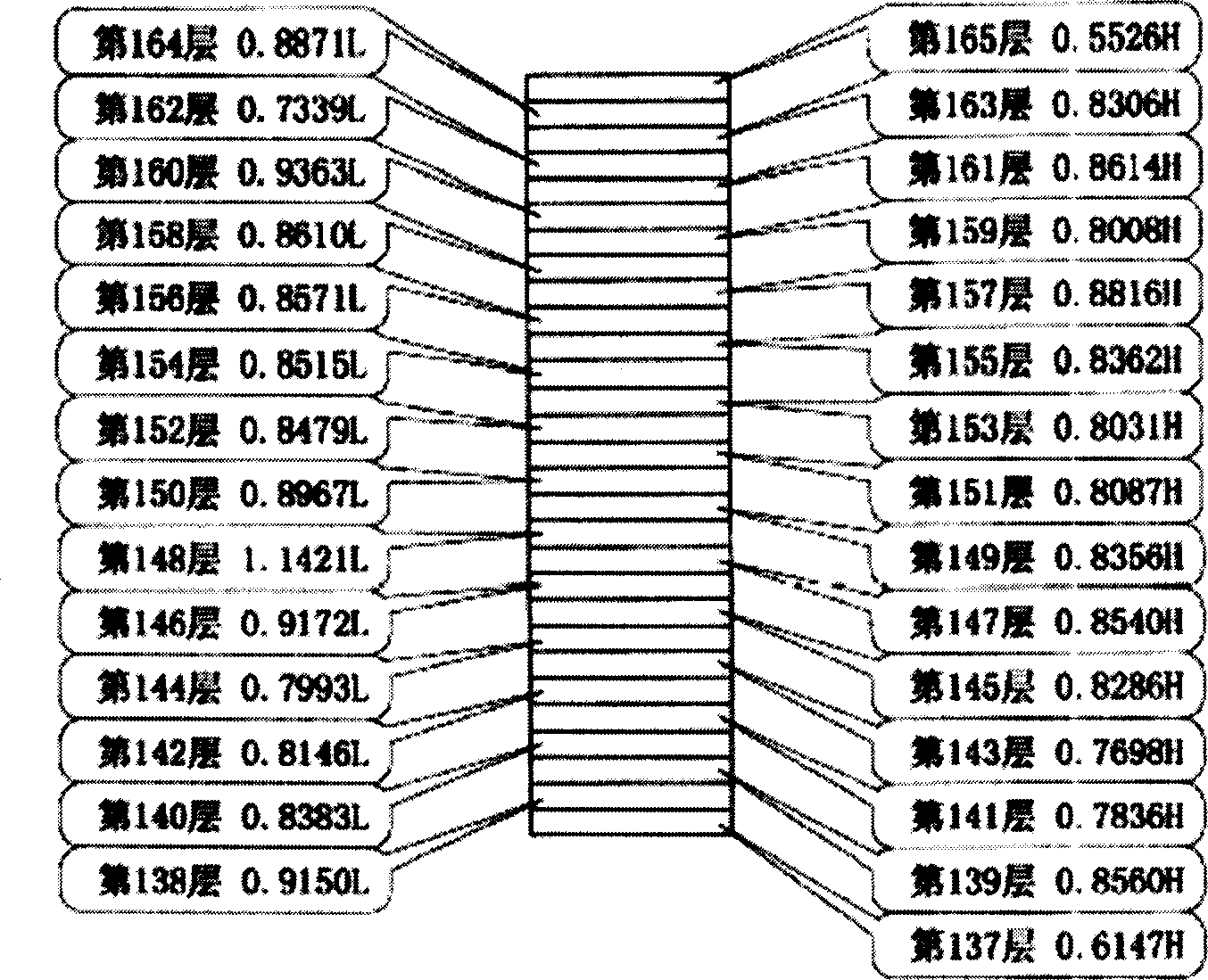

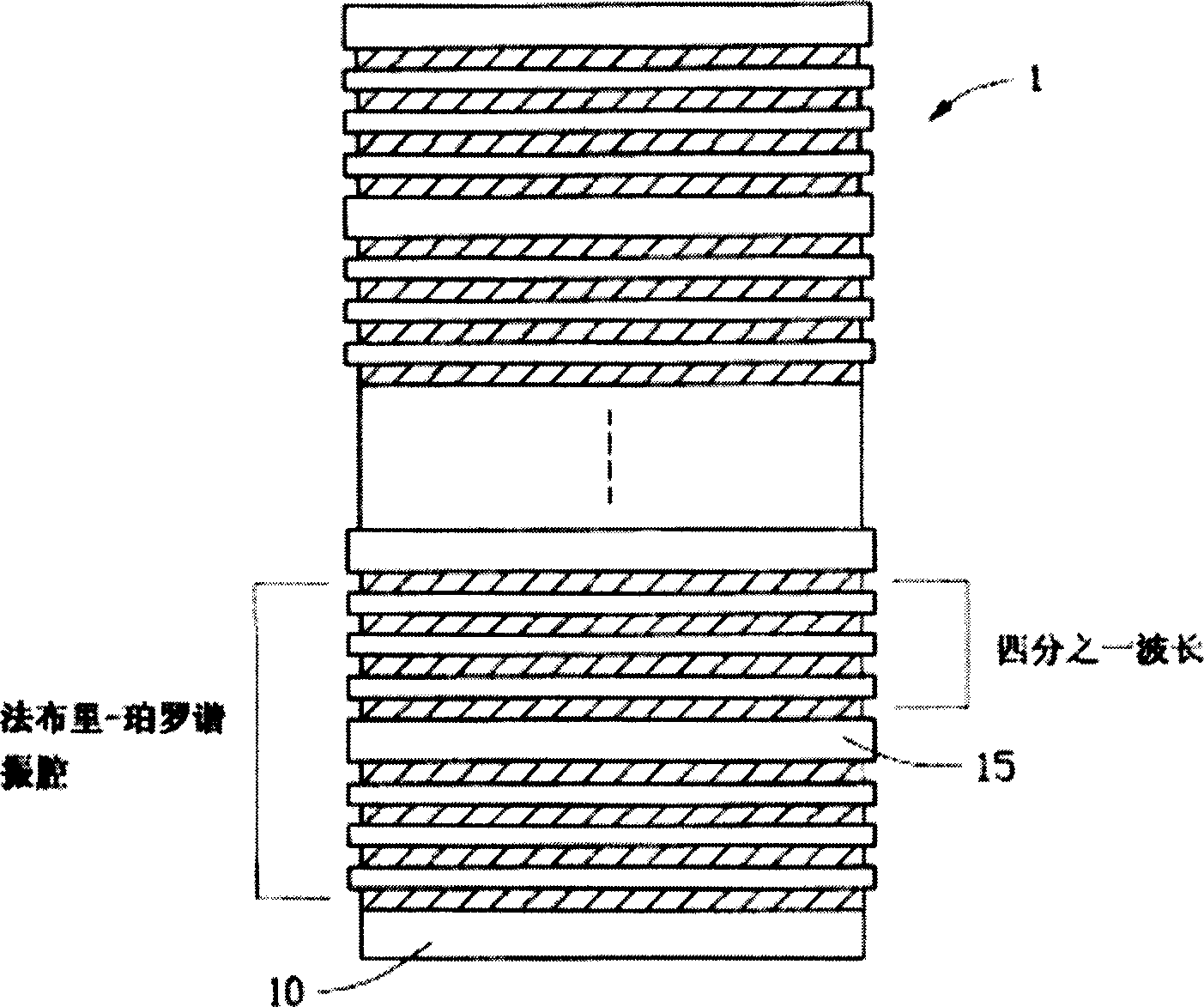

[0026] like figure 1 , 2 As shown in and 3, the present invention relates to a CWDM optical filter 1, including a first part and a second part. Among them, the first part includes at least two Fabry-Perot cavity structures; the second part includes repeated stacking of high and low refractive index film layers on the first part; The layer structure of the wavelength.

[0027]The number of alternately stacked high and low refractive index film layers in the second part can be 28 layers, 40 layers, 50 layers, or 60 layers, etc. The specific number of layers can be determined according to specific requirements and application environment, and the present invention takes 40 layers as the preferred number of film layers for implementation.

[0028] The at least two Fabry-Perot resonator structures of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com