Steel material surface quality examining method

A technology of surface quality and inspection method, applied in the field of surface quality inspection, can solve problems such as poor coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

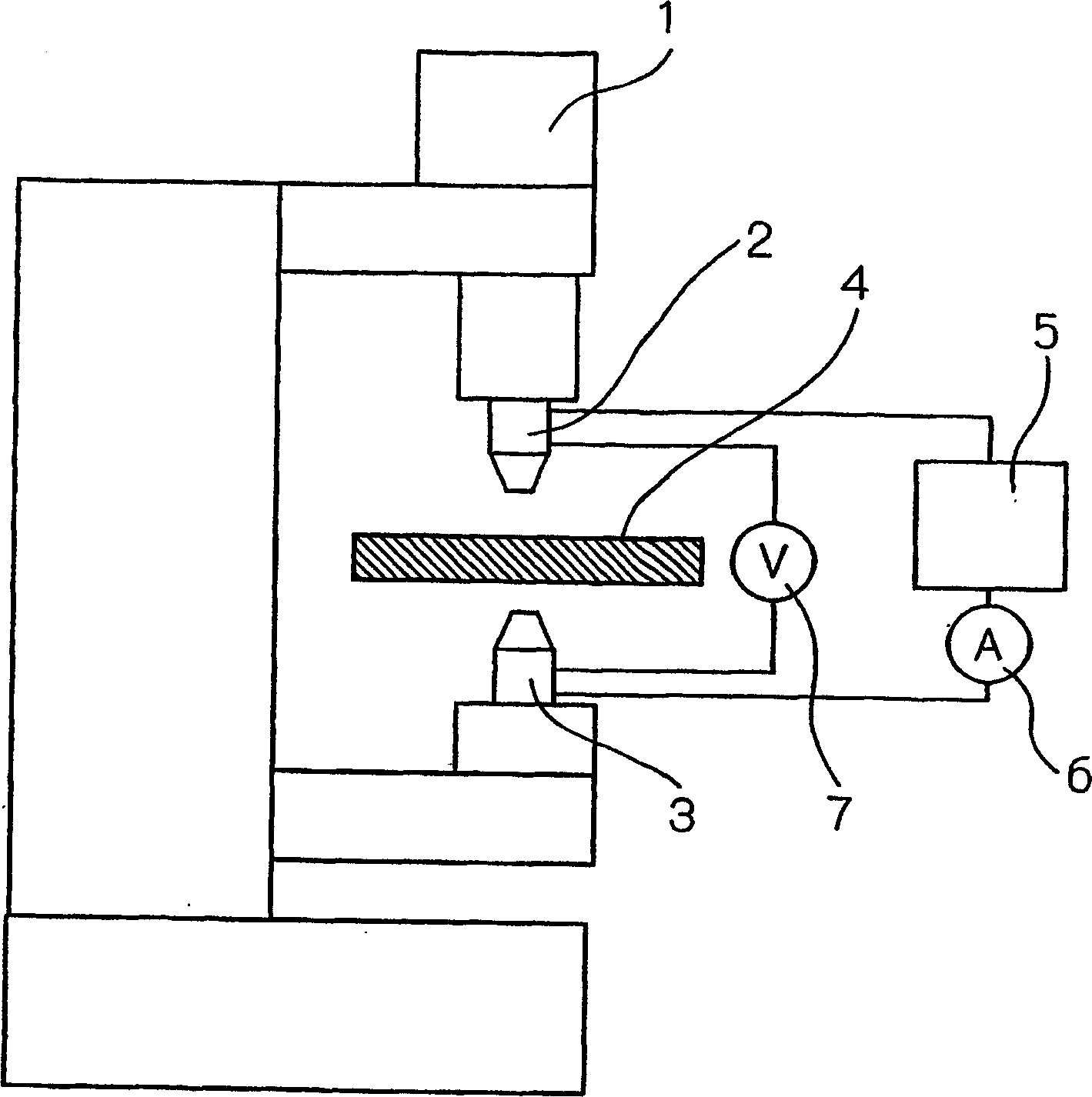

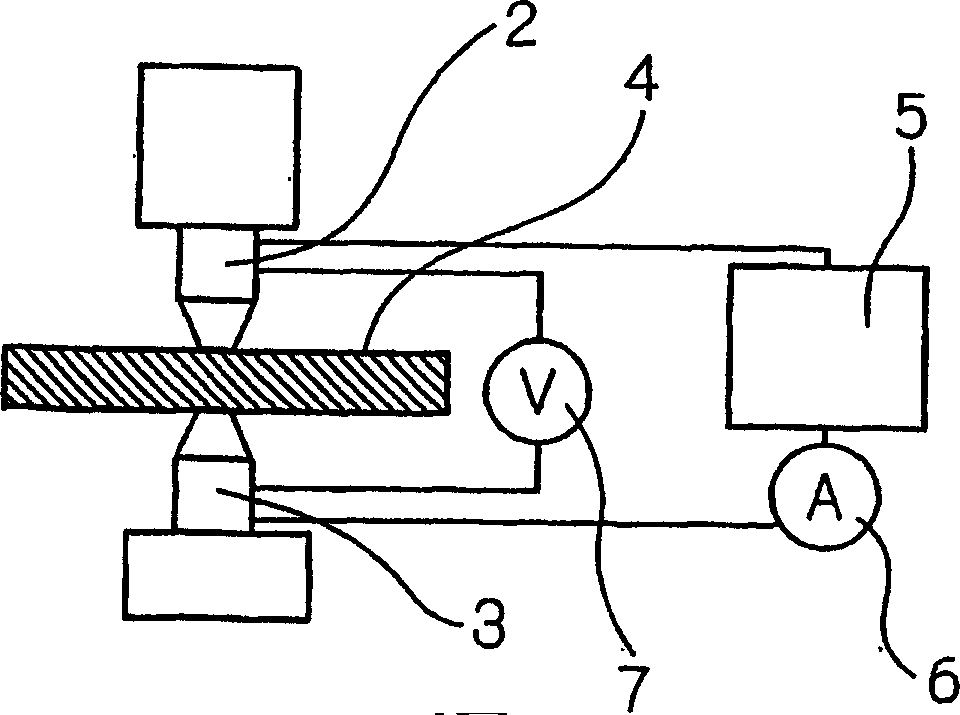

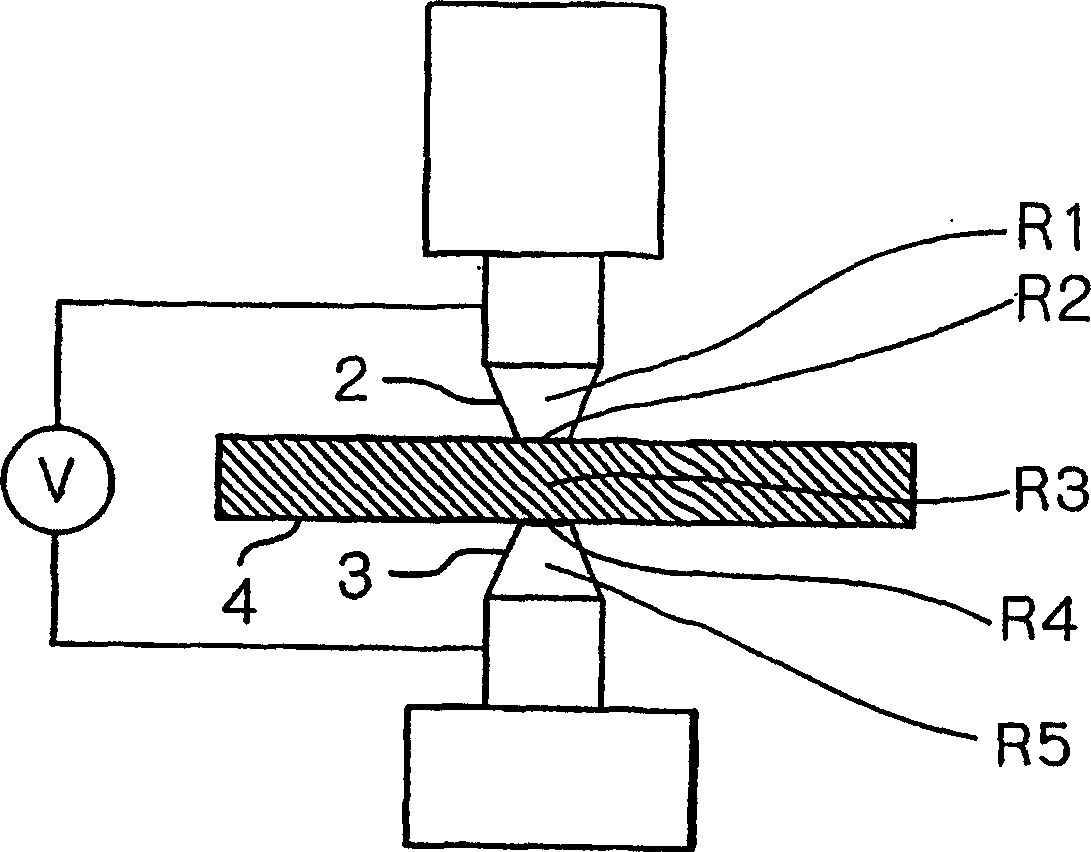

[0087] Using a fixed spot welder as figure 1 The shown pressurization device 1 is used to carry out the method of the present invention. In addition, the measurement terminals 2 and 3 are insulated by removing the copper cable connecting the measurement terminals 2 and 3 and the transformer (not shown). and, if figure 1 As shown, the copper wire of the current generating device 5 and the copper wire of the voltage measuring device 7 are connected to the measuring terminals 2 and 3 .

[0088] set conditions

[0089] Measuring terminal: Cr-Cu electrode, dome radius (dome radius) type

[0090] Base end diameter 16mm Front end diameter 6mm (Front end 40R)

[0091] Pressure: 87N / mm 2 (250kgf)

[0092] Current: DC current 2A

[0093] The "critical value" used as the evaluation standard of the surface quality of the steel sheet is set by repeating operations (a) to (d) as follows: As a sample, a hot-pressed member 4 using a cold-rolled steel sheet with a thickness of...

Embodiment 2

[0101] The difference between this embodiment and the above-mentioned embodiment 1 is that a hot-pressed member obtained by hot-pressing a hot-rolled steel plate with a plate thickness of 1.4 mm was used as a sample. This example is the same as Example 1 except for that.

[0102] The results are shown in Table 2.

[0103]

Sample No

R scale (mΩ)

According to resistance

test result

actually welded

verify results

1

84.2

NG

NG

2

105.3

NG

NG

3

64.3

NG

NG

4

32.5

NG

NG

5

20.7

NG

NG

6

14.0

OK

OK

7

5.1

OK

OK

8

0.4

OK

OK

[0104] The hot-press member 4 judged as "NG" in the inspection result tends to be welded by spot welding. Therefore, it was confirmed that the method of the present invention can accurately inspect spot weldability.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com