Rotary displacement free speed changing device and rotary displacement free speed changing method

A speed change device, a free technology, applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems that the power cannot be compared with the gear speed change, the CVT transmission efficiency is low, and the automatic control is difficult, etc., to achieve light weight, Simple structure, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

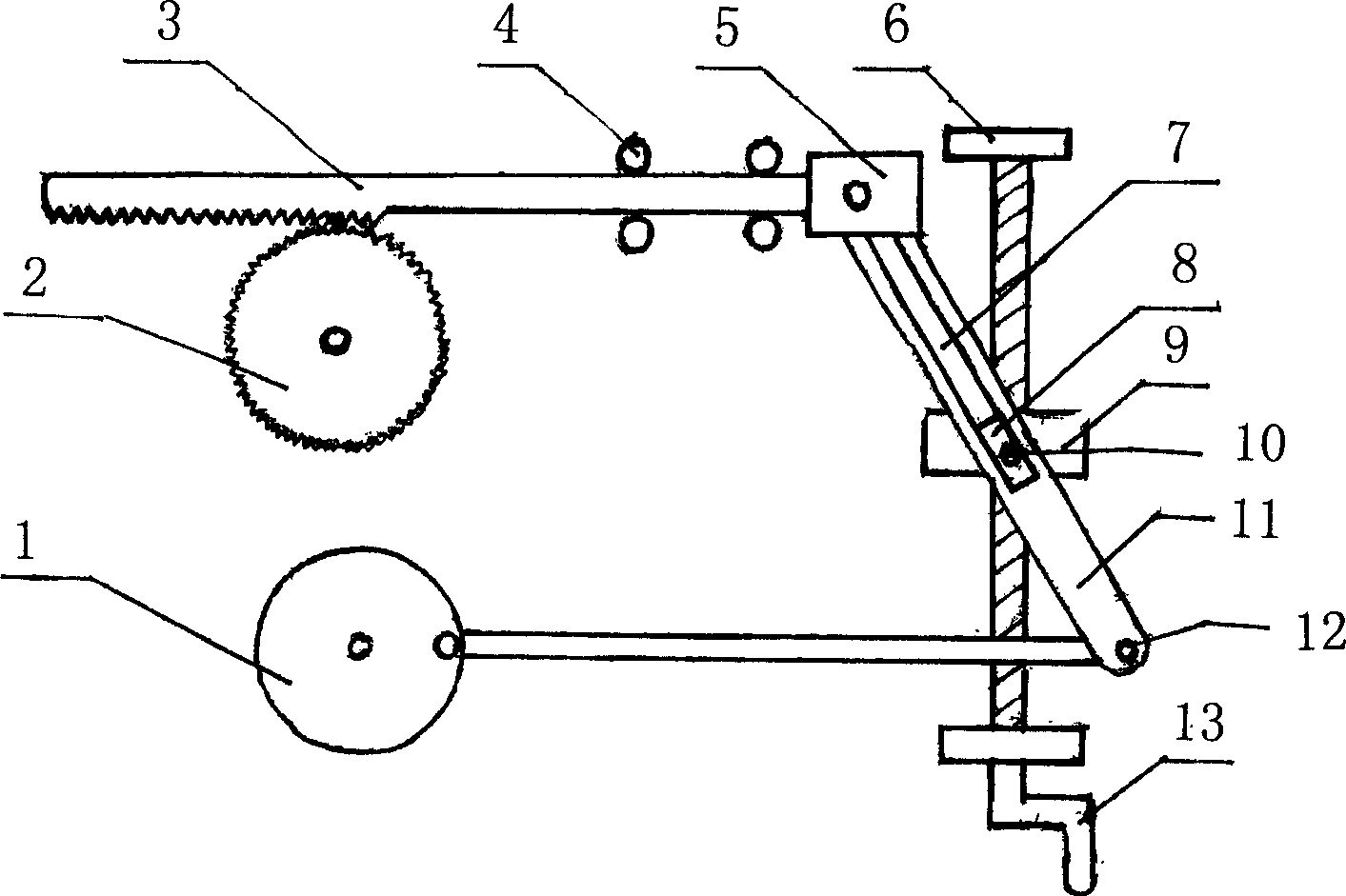

[0026] Accompanying drawing is the embodiment of the present invention

[0027] Below in conjunction with accompanying drawing, content of the present invention is further said:

[0028] refer to figure 1 As shown, the crankshaft linkage mechanism 1 is connected to one end of the rotary shaft 11 through the hinge shaft 12, the rotary shaft 11 is provided with a sliding groove 7, and a sliding block 8 is installed in the sliding groove 7, and the sliding block 8 is fixed to the turbine 9 through the shaft 10. connection, the turbine 9 is inserted into the worm 13 for meshing connection, the two ends of the worm 13 are connected to the support seat 6, the other end of the rotary shaft 11 is connected to the rack end block 5 through a hinge shaft, and the rack end block 5 is connected to the rack 3 The two sides of the rack 3 are provided with guide wheels 4, and the rack 3 is meshed with the one-way gear 2 for transmission connection.

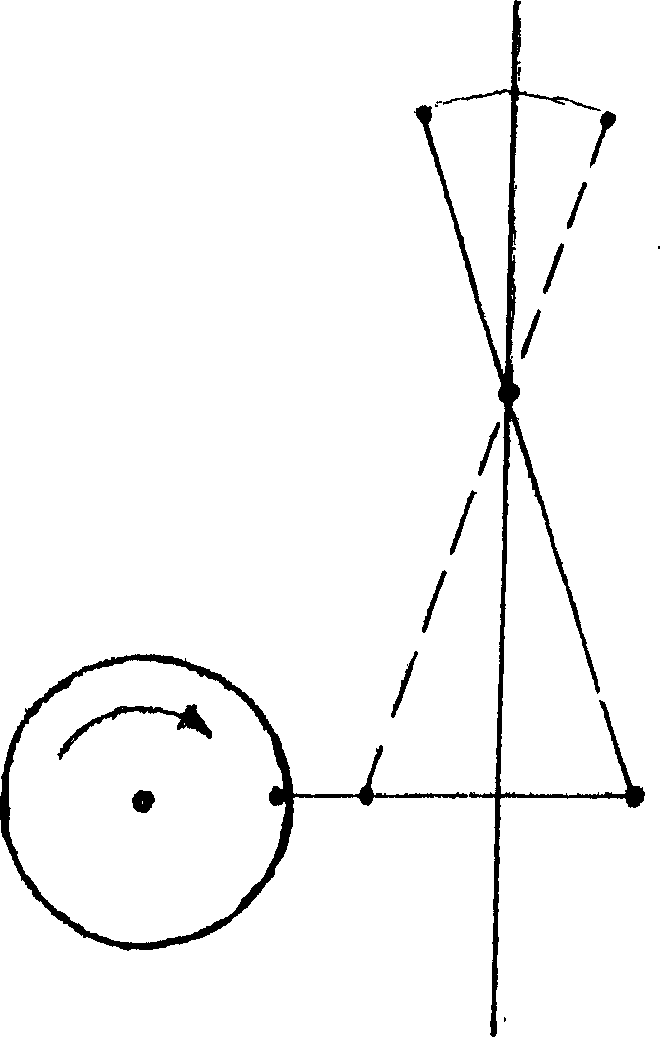

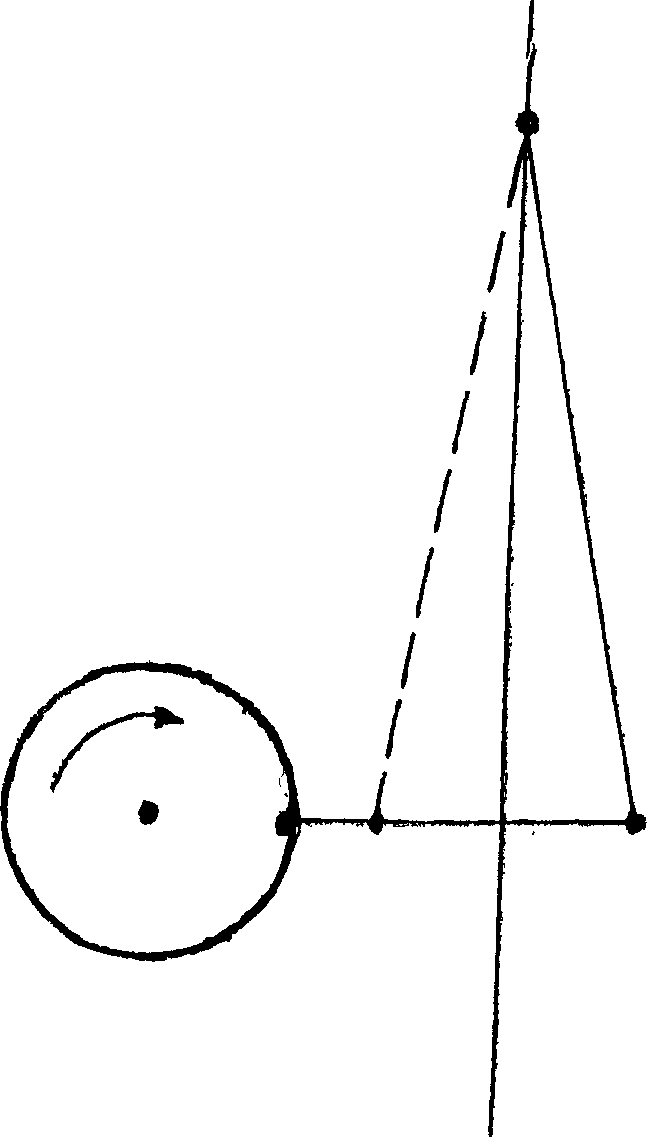

[0029] figure 2 As shown, when the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com